In the core supporting field of building drainage systems, round downpipes have become the preferred components for residential, municipal, and industrial buildings due to their smooth drainage performance and aesthetically pleasing appearance. An efficient and precise forming equipment is the key to ensuring the quality and production capacity of downpipes. The Good Quality Round Downspout Round Pipe Roll Forming Machine, as an intelligent device specifically designed to meet the batch production needs of round downpipes, breaks through the limitations of traditional production with its integrated processing capabilities, providing the industry with a highly efficient and stable production tool to help enterprises seize market opportunities.

Application Scenario:

With its efficient production capacity, stable quality, and flexible adaptability, this circular downpipe forming machine has been widely used in various fields such as construction, municipal projects, and agriculture, becoming a core piece of equipment for processing downpipes in diverse engineering applications.

• In the field of residential architecture

Suitable for the processing of conventional downpipes for projects such as commercial housing, resettlement housing, and old neighborhood renovations, with finished products featuring a smooth and even appearance, adaptable to various architectural styles

• In the field of municipal engineering

It can accurately process large-diameter circular downspouts, meeting the high-intensity drainage requirements for projects such as road drainage, park landscape drainage, and urban pipeline network renovation

• In the fields of industry and agriculture

It can process corrosion-resistant and impact-resistant downpipe fittings for special scenarios such as factory drainage and agricultural irrigation pipelines, ensuring the stable operation of drainage systems in various settings.

Accuracy measurement:

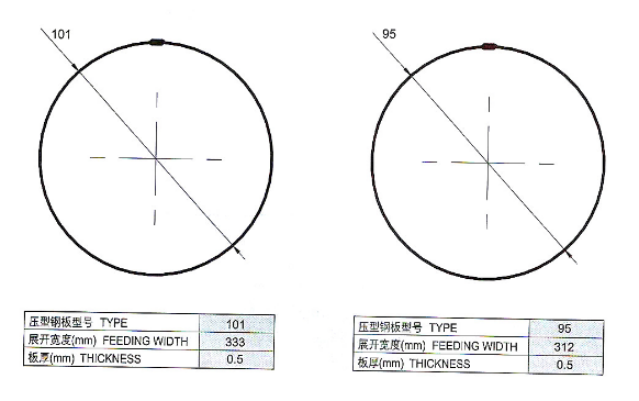

Pattern diagram:

Packing list:

| No | Name | Unit | quantity |

| 1 | 3 tons manual decoiler | Set | 1 |

| 2 | Down Take Pipe Forming Machine with cut part | Set | 1 |

| 3 | Bending machine | Set | 1 |

| 4 | PLC control cabinet | Set | 1 |

| 5 | Hydraulic station | Set | 1 |

| 6 | Run-out table | Set | 1 |

| 7 | Spare parts | Set | 1 |

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI,GL

|

Thickness:0.4-0.8mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

22 rows with a series of vertical rollers

|

||

|

Diameter of shaft

|

70mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

14500*900*1100(customize)

|

|||

|

Weight

|

7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5 KW

|

||

|

Hydraulic system power

|

3.5 KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

Multi dimensional core advantages, building a dual barrier of quality and durability

1. Precision control is the core of the quality of downspouts

This device is equipped with an imported PLC intelligent control system, multiple precision detection and stability protection mechanisms, achieving millimeter level molding accuracy control, ensuring that the diameter and wall thickness of each downspout are uniform and consistent, the spiral lock seam is tight and firm, and common quality problems such as water leakage, deformation, and loose interfaces are eliminated from the source. The finished product qualification rate can reach over 99.8%.

2. In terms of durability

The key components of the equipment are made of high-quality materials: the roller shaft is made of 40Cr material that has undergone quenching and tempering treatment, with a hardness of HB280 and wear resistance; The forming mold is made of GCr15 steel quenched and processed, with a hardness of HRC56-62 ℃. It can withstand long-term rolling and forming of various metal raw materials, and its service life is extended by more than 30% compared to ordinary equipment. At the same time, the equipment adopts gearbox transmission instead of traditional hydraulic transmission, reducing energy consumption by 27%, in line with the green production concept under the dual carbon target, and balancing efficiency and environmental protection.

3. The humanized design is full of highlights

The fully automatic hydraulic cutting system can accurately cut according to the preset length, with a smooth and burr free cut and no need for secondary polishing; Optional shrinking and bending auxiliary modules are available, which can be integrated to complete 45 degree, 90 degree, and S-shaped joint processing, eliminating additional processes and further improving production efficiency and product added value.