Today, as the construction industry moves towards lightweighting and assembly, the keel machine, as the core equipment of cold bending forming technology, is becoming the “hidden champion” of efficient production of partition walls and ceiling systems. High-Speed Steel Keel Profile Roll Forming Machine For M6 M10 Beacon Channel, with innovative design and precision technology, provides construction enterprises with a full process solution from materials to finished products, helping customers reduce costs and increase efficiency, and seize market opportunities.

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness: 0.32mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

10rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

3KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

70m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Packing list:

| N/M | Item | Unit | Quantity |

| Part 1 | 3t hydraulic decoiler | set | 1 |

| Part 2 | High speed punching machine with servo feeder | set | 1 |

| Part 3 | Main roll forming machine | set | 1 |

| Part 4 | PLC control system | set | 1 |

| Part 5 | Hydraulic system | set | 1 |

| Part 6 | 3m collecting product table | set | 1 |

| Part 7 | Tools | set | 1 |

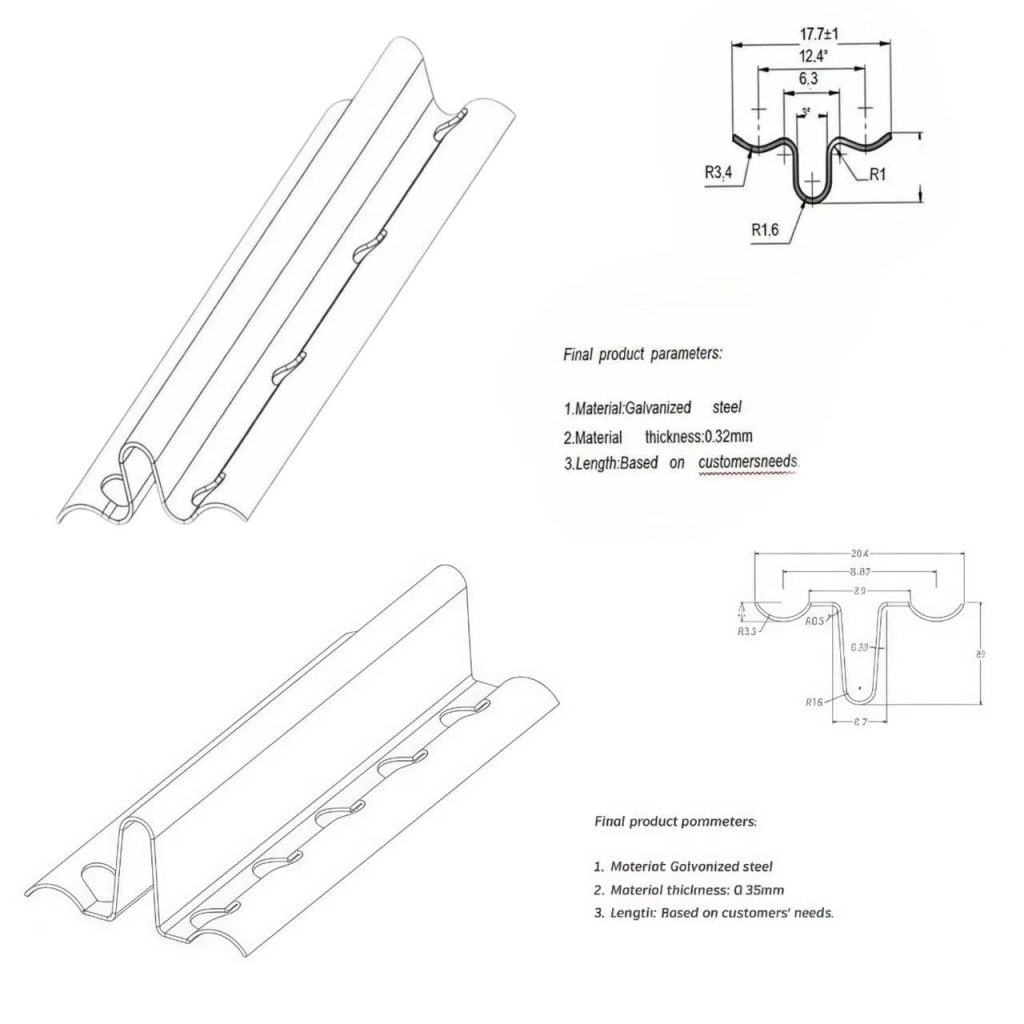

Pattern diagram:

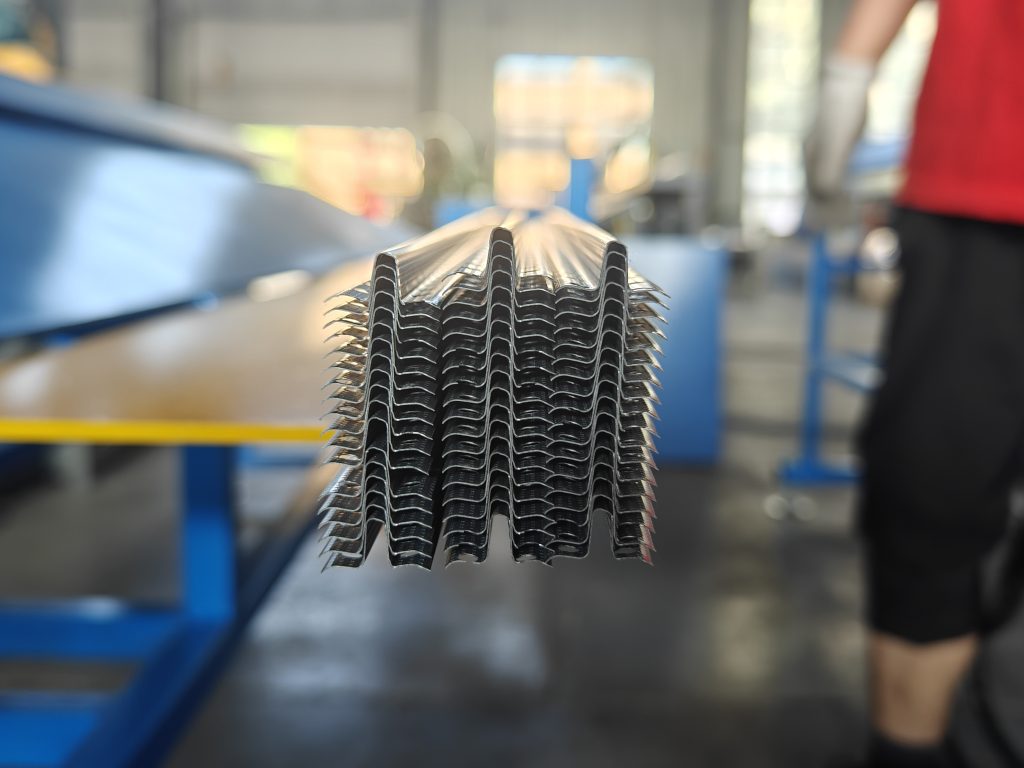

Core technological advantage: dual breakthrough in precision and efficiency

1.High speed continuous production, doubling production capacity

By optimizing the forming roller group and transmission system, the production speed can reach 6-13 meters per minute, and the single shift production capacity breaks through the limitations of traditional processes. Cooperate with the automatic cutting and receiving system to achieve the full process automation of “feeding forming cutting stacking”, reduce manual intervention, and improve the yield rate.

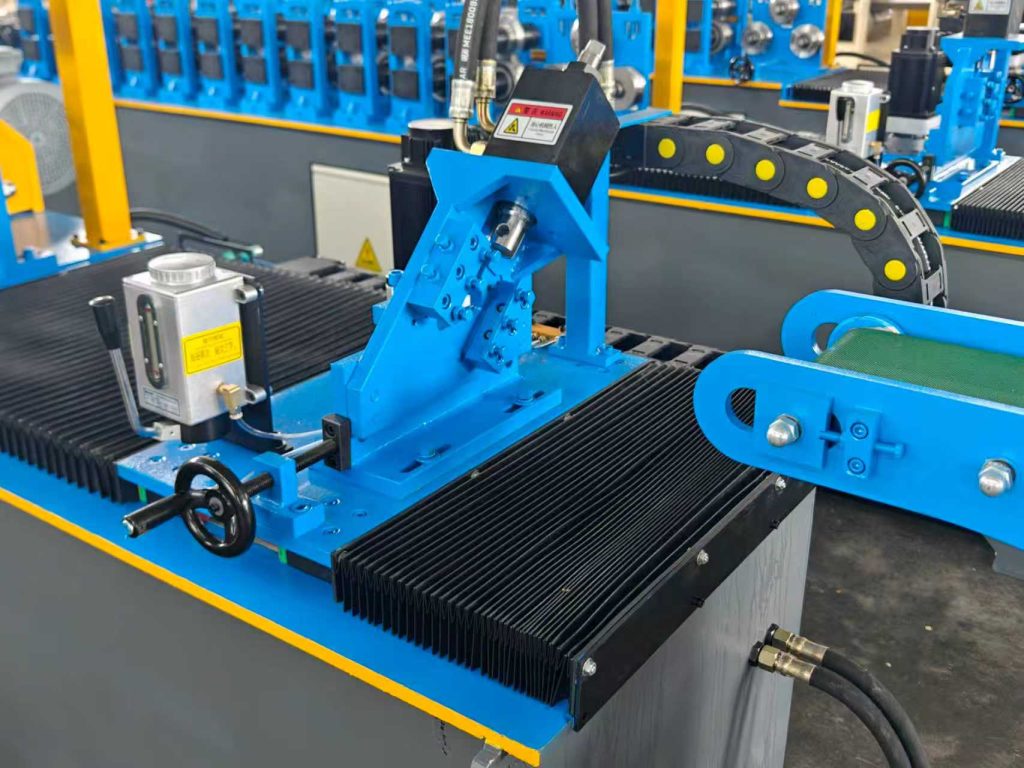

2.Intelligent control, stable quality

Integrated PLC control system and touch screen human-machine interface, real-time monitoring of molding pressure, speed, dimensional accuracy and other parameters, automatic correction and alarm functions ensure product consistency. Through the data traceability system, production anomalies can be quickly located and the scrap rate can be reduced.