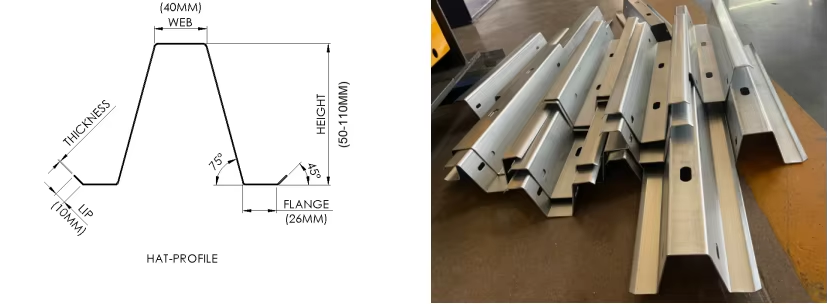

In the field of modern architectural decoration, light steel keel has become the core material for ceiling and partition construction due to its lightweight and sturdy characteristics. As an important branch of light steel keel, hat shaped keel is leading the new trend of architectural decoration with its unique shape and excellent performance. The Metal Omega Furring Channel Forming Machine Furring System , as a key equipment for producing hat shaped keels, is injecting a continuous stream of innovative vitality into the construction decoration industry with its efficient and precise characteristics.

Application Scenarios :

• In the field of architecture

The keel products produced by the hat type keel machine are widely used in light steel keel systems as the skeleton of suspended ceilings, partition walls, floor slabs, and external wall support structures. For example, in light steel villas, industrial plants, and commercial buildings, they can effectively improve the seismic resistance and space utilization of buildings; The thickness range of materials processed by the equipment is usually 0.8mm to 3.5mm, compatible with corrosion-resistant materials such as galvanized steel plates, ensuring durability in humid or high load environments.

• In industrial manufacturing

This equipment is suitable for processing structural components in automated production lines, such as storage shelves, mechanical equipment frames, etc. Its hydraulic post cutting system and high-precision forming technology (speed up to 45m/min, cutting accuracy ± 1mm) can meet the production needs of large quantities and high consistency.

• In the field of transportation

Hat shaped keel may be used in the manufacturing of vehicle chassis, container frames, or rail transit components. Thanks to its aluminum alloy body design and automatic tension control function, the equipment can adapt to dust-free or high cleanliness environments, indirectly supporting the production of structural components for medical equipment or food packaging machinery.

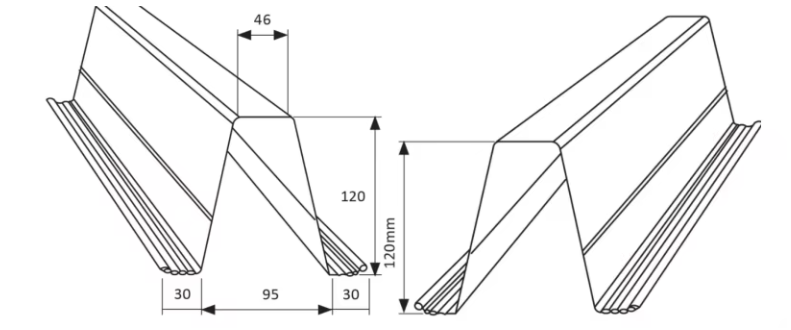

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.4-0.8mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

40-45m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Hat type keel machine: the core tool for efficient production

1.Precise molding, excellent quality

The hat shaped keel machine adopts advanced cold bending technology, which can accurately bend the metal coil into the standard shape of the hat shaped keel. This technology ensures the consistency and stability of the keel size, enabling each keel to meet strict dimensional accuracy requirements. During the production process, the equipment is equipped with precise measurement and control systems that can monitor and adjust the forming parameters in real time, ensuring that the geometric shape and dimensional accuracy of the keel meet the design standards. This precise molding ability enables the hat shaped keel to fit tightly during installation, reducing gaps and misalignment, and improving overall installation quality.

2.Efficient production, increased production capacity

The hat shaped keel machine has efficient production capacity and can quickly process metal coils into hat shaped keels. Its high degree of automation reduces the need for manual operations and improves production efficiency. At the same time, the equipment is also equipped with a quick mold changing system, which can quickly change molds according to different specifications of keel requirements, achieving flexible production of multi specification products. This efficient production method not only reduces production costs, but also meets the large demand for hat shaped keels in the market, providing timely and sufficient material supply for building decoration projects.

3.Durable and sturdy, stable operation

During the production process, the hat type keel machine needs to withstand significant mechanical force and pressure, therefore its structural design is sturdy and durable. Made with high-quality steel and reinforced technology, the equipment has good resistance to deformation and wear, and can maintain stable performance under long-term high-intensity use. The key components of the equipment, such as the transmission system and molding molds, have undergone special treatment and strengthening to improve their wear resistance and service life. This sturdy and durable feature enables the hat type keel machine to produce continuously and stably, reducing failures and downtime, and bringing long-term economic benefits to users.