Full Automatic Roofing Accessories Making Drip Edge Roll Forming Machine

In construction projects, rainwater erosion is always a hidden killer that threatens the safety of wall structures and affects the lifespan of buildings. From mold and peeling off of residential exterior walls to leakage of curtain walls in commercial buildings, from weathering damage of cultural relics and historic sites to structural corrosion of industrial plants, problems caused by rainwater are constantly emerging. As a key component of building waterproofing systems, Full Automatic Roofing Accessories Making Drip Edge Roll Forming Machine is empowered by technology to break traditional limitations and provide efficient, durable, and precise rainwater drainage solutions for various types of buildings, becoming an indispensable core equipment in modern construction engineering.

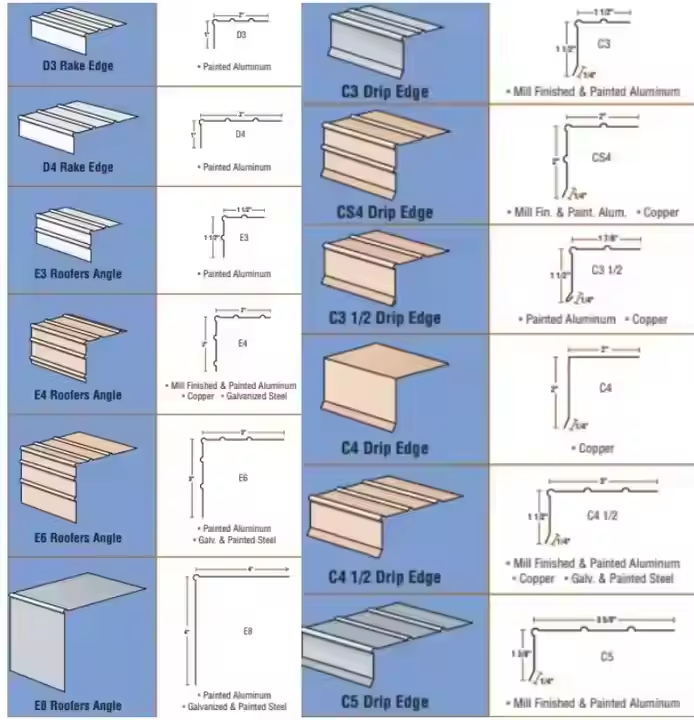

Pattern diagram:

Global adaptation, empowering diverse architectural scenes

• In residential and commercial buildings

aluminum alloy drip eaves can be processed by equipment to adapt to exterior wall decoration and roof waterproofing projects, providing strong home protection for thousands of households.

• In the industrial field

the finished products processed by specialized drip eaves equipment for color steel accessories replace traditional bending machine operations, providing efficient waterproof solutions for color steel roofs such as factories and warehouses.

Product Attributes :

|

1.Formed Material

|

PPGI,PPGL,AI,Etc.

|

Material Thickness:0.5-0.7mm

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

14 rows (as your requirement)

|

||

|

Diameter of shaft

|

60mm solid shaft

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

Due to your requirement profile

|

|||

|

Drive

|

gear and Double Chain transmission/gearbox transmission optional

|

|||

|

Dimension(L*W*H)

|

Due to design

|

|||

|

Weight

|

Due to design

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW(normally)

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

As your requirement

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

0-45m/min

|

Provide customized

|

||

Multi dimensional advantages, building the first line of defense for building protection

1.In terms of protective performance

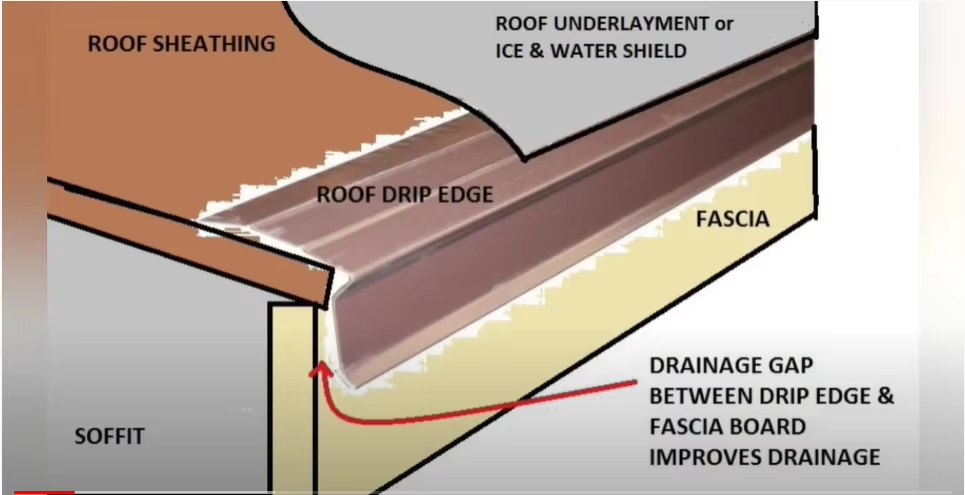

the drip eaves processed by professional equipment have achieved precise rainwater drainage through scientific structural design. The drip line in the shape of an eagle beak can forcibly change the direction of rainwater flow, guiding it to areas far away from walls and foundations, effectively avoiding problems such as wall mold and structural corrosion caused by rainwater infiltration. It is especially suitable for areas such as balconies, bay windows, and eaves where rainwater is prone to accumulate. Paired with an integrated glass fiber mesh structure, it can enhance the crack resistance of wall connections, improve the stability of the overall waterproofing system, and extend the service life of the building.

2.In terms of economy and convenience

the new generation of drip eaves equipment has achieved a dual optimization of cost and efficiency. The finished products processed by the equipment do not require complex cutting and adjustment, and can be directly embedded into the wet primer for quick installation, greatly reducing on-site construction time and labor costs; Finished products made of materials such as plastic and aluminum alloy are lightweight and have strong weather resistance. They can resist strong ultraviolet rays, wind and rain erosion, and can be freely cut to adapt to different building sizes. They are suitable for various scenarios such as new construction projects and old house repairs. For large-scale construction projects, standardized processing of drip eaves can better ensure construction consistency, reduce maintenance costs in the later stage, and achieve long-term cost-effectiveness maximization.

3.In terms of aesthetics and compatibility

drip eaves devices better balance building functionality and aesthetic quality. The finished products processed by factory standardization have smooth edges and lines, which can perfectly fit various exterior wall materials and roof shapes, avoiding the roughness of traditional manual craftsmanship and enhancing the overall beauty of the building. At the same time, the device supports multi material and multi specification customization, which can accurately adapt to the simple style of modern commercial buildings or the “repair as old” needs of cultural relics protection projects, achieving a harmonious unity of protection and aesthetics.

Choose professional equipment to safeguard the long-term value of buildings

Choosing equipment is not only about choosing efficient processing tools, but also about choosing a long-term construction guarantee. Making every eaves a precise node for rainwater drainage, ensuring that every building can withstand the erosion of time and maintain stability and beauty in wind and rain, is the core strength injected by drip eaves equipment into modern architecture.