Full Automatic Metal Unistrut Rack Solar Bracket for U Solar Strut Channel Roll Forming Machine

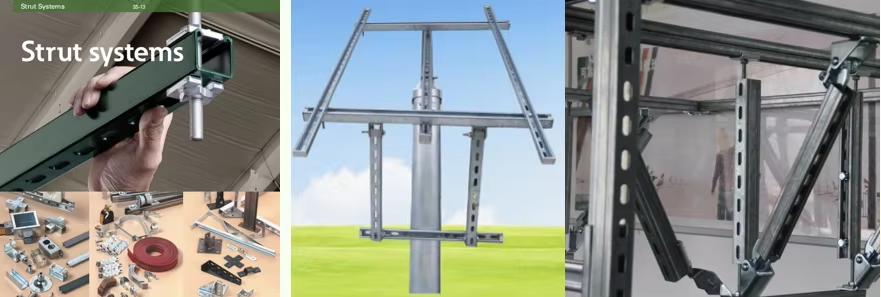

In the wave of clean energy revolution sweeping the world, photovoltaic power generation has become a key force in promoting energy transformation due to its pollution-free and sustainable characteristics. In this hopeful green field, Full Automatic Metal Unistrut Rack Solar Bracket for U Solar Strut Channel Roll Forming Machine is quietly playing a crucial role – it is not only the “skeleton” of solar photovoltaic panels, but also the cornerstone of the efficient and stable operation of the entire system.

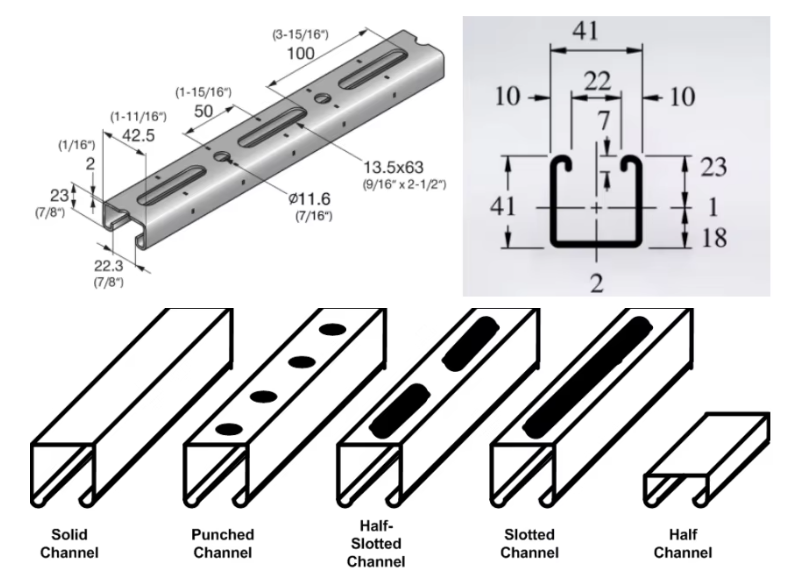

Pattern diagram:

Core Features:

1. High strength and durability: addressing the challenges of extreme environments

Our photovoltaic brackets are made of advanced materials such as high-strength aluminum alloy and hot-dip galvanized steel, and are crafted with precision technology to have excellent load-bearing capacity and wind pressure resistance. Under the extreme weather conditions of strong wind, rainstorm or snow cover, the support is still stable, ensuring the safety of the photovoltaic system and providing a solid guarantee for the continuous output of green energy.

2. Corrosion resistance and oxidation resistance: suitable for complex outdoor environments

Faced with the ever-changing outdoor climate conditions, the bracket material has undergone special anti-corrosion treatment, demonstrating excellent corrosion resistance and oxidation resistance. Whether in humid coastal areas, saline alkali land, or high-altitude environments, brackets can maintain stable performance for a long time, effectively extending the service life of photovoltaic systems and reducing maintenance costs.

3. Intelligent regulation and efficient power generation: improving energy utilization efficiency

The intelligent tracking system with innovative design enables the bracket to automatically adjust its angle according to the position of the sun, achieving “chasing the light while walking”. This technology significantly improves the power generation efficiency of photovoltaic panels, especially during periods of abundant sunlight resources in the morning and evening. It can significantly increase the amount of electricity generated, allowing every ray of sunlight to be fully utilized and bringing higher economic benefits to the power station.

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

60mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

customize

|

|||

|

Weight

|

About 6.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

20m/min(customized)

|

Speed is adjustable according to customer’s request

|

||