In the current pursuit of “efficiency, durability, and aesthetics” within the construction industry, trapezoidal roof tiles have emerged as the preferred roofing material for various structures, including industrial factories, warehousing and logistics centers, residential villas, and agricultural markets. Their tightly sealed waterproofing, visually balanced three-dimensional appearance, and long-lasting corrosion resistance make them an ideal choice. The key to capturing the market has always relied on a “high-performance” production machine—Hot Sale Trapezoid Steel Roof Tile Making Machine , which serves as the core tool to reduce costs, enhance competitiveness, and unlock new wealth opportunities!

Product Attributes:

|

No.

|

Item

|

Specification

|

||

|

Material

|

Raw material

|

Galvanized steel or PPGI,PPGL,AI

|

||

|

Thickness

|

0.3-0.8 mm

|

|||

|

Decoiler

|

Operation

|

Manual(buy machine give you free) Or Hydraulic

|

||

|

Weight capacity

|

3T 5T 7T 10T

|

|||

|

Machine

|

Roller station

|

10-18(depend on customer’ drawing)

|

||

|

Shaft diameter

|

70-80mm

|

|||

|

Body frame

|

350H steel

|

|||

|

Roller material

|

Cr12

|

|||

|

Machine size

|

About 6.5*1.5*1.2 m

|

|||

|

Machine weight

|

4-8 tons

|

|||

|

Drive

|

gear and Double Chain or gearbox

|

|||

|

Working speed

|

12-60 m/min

|

|||

|

Hydraulic Cutting

|

Cutter Hardness

|

50-65 HRC

|

||

|

Cutter Material

|

Cr12

|

|||

|

Cutting tolerance

|

± 1mm

|

|||

|

Power

|

Main motor

|

5.5kw

|

||

|

Pump motor for cutter

|

7.5kw

|

|||

|

Control system

|

PLC brand

|

Delta or Siemens

|

||

|

Touch screen

|

Delta or Siemens

|

|||

|

Language

|

6000+ languages customized according to customer needs

|

|||

|

Voltage

|

380V/50HZ, 3P

|

customized according to customer needs

|

||

Choosing us is not just a machine, but also a worry free profit guarantee throughout the entire process!

We have been deeply involved in the machinery manufacturing industry for many years, strictly controlling every production process to provide you with high-quality and cost-effective trapezoidal roof tile machines. At the same time, it is equipped with comprehensive pre-sales consultation (providing free capacity planning and site layout plans), in sales installation and commissioning (professional team on-site guidance), and after-sales maintenance (24-hour response, quickly solving faults) full chain services, allowing you to purchase the machine without risk and production without concerns.

Whether a startup building materials factory wants to quickly open up the market or an established enterprise wants to upgrade equipment and expand production capacity, this Hot Sale Trapezoid Steel Roof Tile Making Machine can become your profit partner, helping you seize the dividends in the huge potential roof tile market and achieve a two-way surge in production capacity and profits!

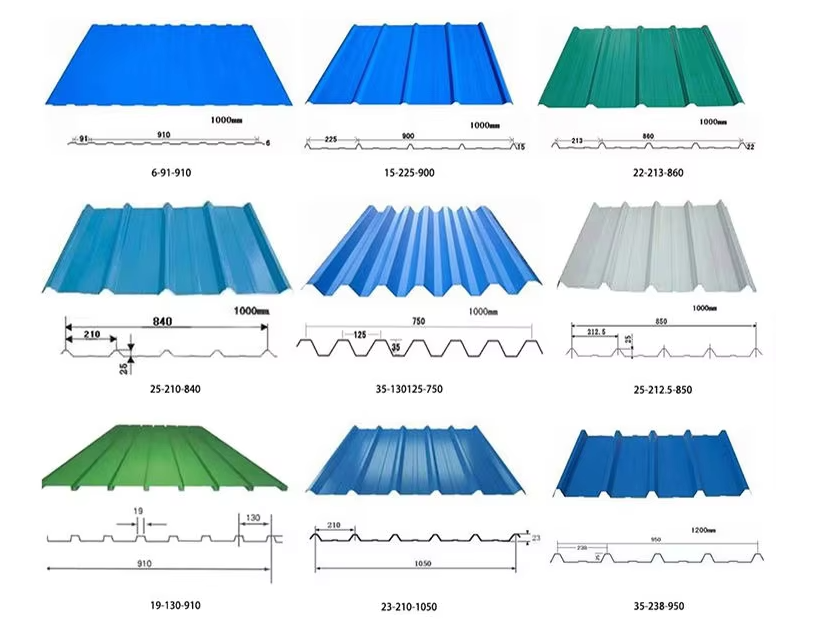

Pattern diagram:

core advantages

1. High production efficiency, handling even the largest orders with ease

Equipped with an advanced PLC automation control system, the process of raw material feeding, shaping, and cutting can be completed with a single button press, achieving an output of 1,200-1,800 meters per hour and a 30%+ efficiency boost. The intelligent feeding mechanism ensures a 99% raw material utilization rate, effectively reducing costs and enhancing productivity.

2. Precision Craftsmanship, Tile Pass Rate 99%+

The core pressure roller of CNC machining has a hardness of HRC55+, a tile-type error of ±0.5mm, and excellent waterproof performance. It supports various materials and raw materials with thicknesses ranging from 0.3 to 1.2mm. The finished product is resistant to compression and wear, easily meeting diverse requirements.

3. Hassle-free and Effortless, Even Novices Can Get Started Quickly

The high-definition touch screen features intuitive operation, allowing operators to work independently after just 1-2 days of training. The reinforced steel structure, paired with renowned brand accessories, requires only basic maintenance in daily use, reducing costs by up to 40%.

4. Energy Conservation, Environmental Protection, and Green Production for Greater Competitiveness

The power system has been upgraded, reducing energy consumption by 25% and maintaining noise levels below 75 decibels. With zero wastewater and exhaust emissions, it helps enterprises adhere to environmental protection standards and seize market opportunities.

5. Customized Adaptation, Covering All Scenario Needs

Supports wave-shaped personalized customization, allowing flexible adjustments to parameters such as wave height and wavelength. Suitable for various architectural scenarios, from industrial factories to residential villas, creating differentiated advantages.