The glazed tile roll foming machine is an automated equipment that uses metal sheets such as color steel plates and aluminum alloy plates as raw materials to produce roof building materials with both antique appearance and metallic characteristics through multiple processes. It solves the drawbacks of traditional glazed tiles, achieves standardized molding and pattern restoration of metal tiles, ensures coating adhesion, meets modern architectural needs, and is applied in various building scenarios.

Applicable scenarios and selection suggestions

1. Small regional building materials factory (with a production capacity of 500-1000 pieces/day, serving rural residential areas)

• Selection: Semi automatic roll forming machine (equipped with simple leveling, manual feeding, optional laminating)

• Advantages: Investment of 200000 to 350000 yuan, easy to operate; Roller pressing technology is suitable for lightweight requirements and coated with film to prevent damage.

2. Medium sized building materials enterprises (with a production capacity of 1000-3000 pieces/day, balancing conventional and antique styles)

• Selection: Composite molding machine (roller press+stamping linkage, semi-automatic/fully automatic), equipped with automatic leveling and waste recycling

• Advantages: Efficient mass production and customized patterns, fully automatic cost reduction and quality improvement.

3. Large scale metal building materials base (with a production capacity of over 3000 pieces/day, undertaking large-scale projects)

• Selection: Fully automatic production line (including online color coating, automatic stacking, MES system)

• Advantages: 1-2 people monitor the entire process, integrated color coating, MES ensures batch quality.

4. Ancient building restoration/high-end customization (small batch high-precision special tiles)

• Selection: Customized stamping machine (multiple sets of antique molds)+manual trimming

• Advantages: Accurately restoring the texture of ancient buildings, hand polishing ensures perfect details.

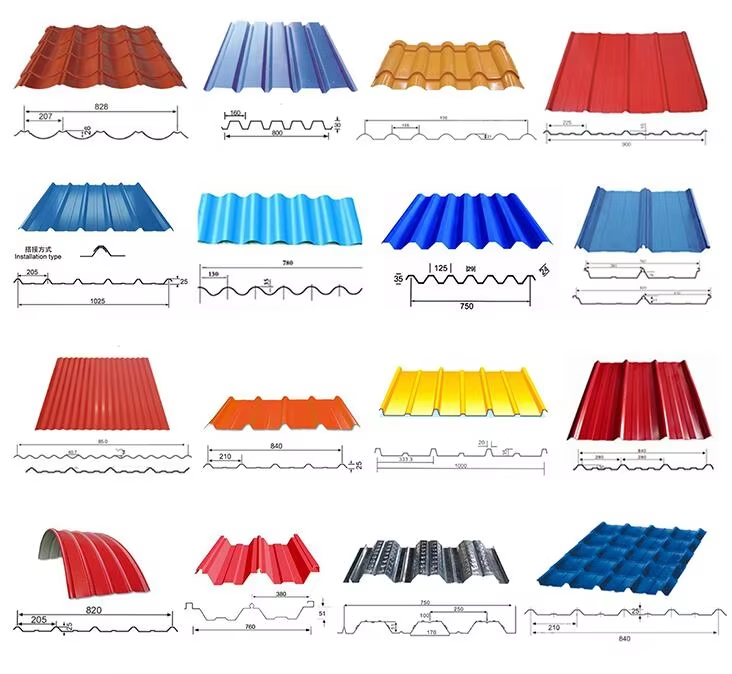

Pattern diagram:

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.3-0.8mm Width:1000mm/1250mm(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

13 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

9500*1600*1600(customize)

|

|||

|

Weight

|

11T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW

|

||

|

Hydraulic system power

|

15KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

8-9m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||