In modern architectural material processing, the Gutter and Downspout Roll Forming Equipment is an automated device for producing core components of roof drainage systems. Utilizing continuous forming technology, it transforms metal coils such as color steel plates and aluminum alloy sheets into gutters and downpipes, widely used in drainage systems for factories, residences, and other buildings, significantly enhancing production efficiency and standardization levels.

Equipment advantages

Compared to traditional manual welding and cutting of gutter downspouts, machine production has significant advantages:

• High efficiency:

Automated continuous production, with a daily output of 800-1500 meters per machine, far exceeding manual processing (manual daily output is less than 100 meters).

• Stable quality:

The rolling mill has high forming accuracy, avoiding size deviations and welding leaks caused by manual processing. The sealing and load-bearing capacity of drainage components are more reliable.

• Low cost:

Reduce labor costs (only 1-2 people are needed to operate one machine), while reducing raw material waste (the scrap rate can be controlled within 3%).

• Strong flexibility:

By replacing the forming rollers (which can be completed in 1-2 hours), different cross-sections of gutters or downspouts can be produced to meet the needs of various types of orders.

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI,GL

|

Thickness:0.4-0.8mm

Downspout size:2”*3”,3”*4”

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

19 rows with a series of vertical rollers

|

||

|

Diameter of shaft

|

70mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

11000*900*1100(customize)

|

|||

|

Weight

|

4.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5 KW

|

||

|

Hydraulic system power

|

4 KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

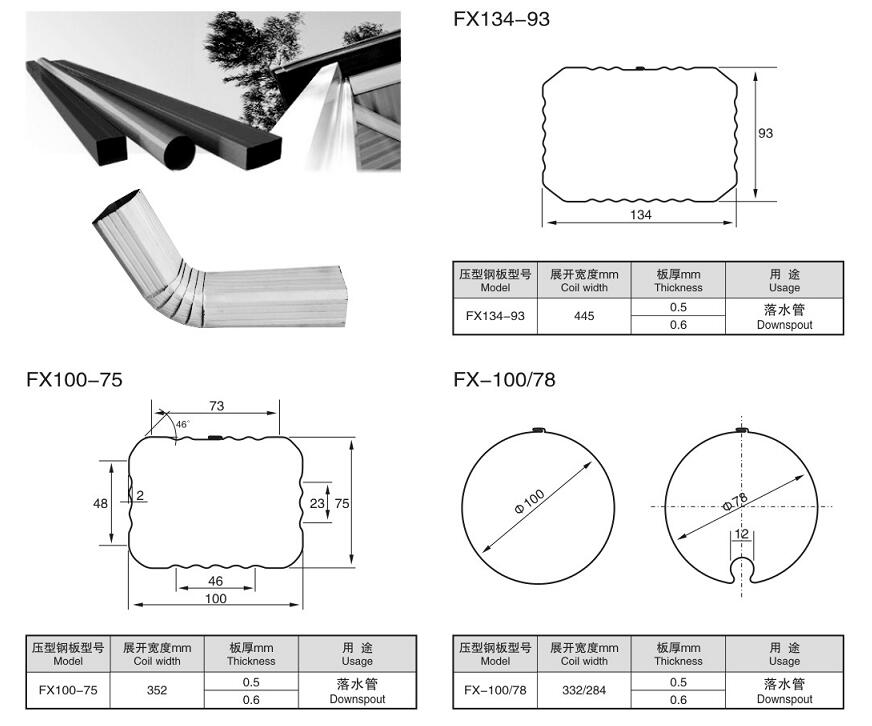

Core functions and working principles that Gutter and Downspout Roll Forming Equipment

1. Roll unwinding:

By using a unwinding machine, the rolled metal raw materials (usually color steel coils and aluminum coils with a width of 100-600mm and a thickness of 0.3-1.2mm) are smoothly released. At the same time, a tension control system is equipped to prevent the coil from deviating or wrinkling, ensuring feeding stability.

2. Leveling preprocessing:

Metal coils are prone to bending and deformation during long-term storage, and need to be compressed by multiple sets of rollers of a leveling machine to restore the coil to a flat state, laying the foundation for subsequent forming accuracy.

3. Continuous cold bending forming:

This is the core component of the equipment. The flattened metal plate enters the forming machine and is gradually extruded, bent, and shaped by 10-20 sets of forming rollers designed according to specific trajectories, ultimately forming the cross-sectional shape of a gutter (such as U-shaped, semi-circular) or a downspout (such as circular, square, rectangular). The entire process does not require heating and relies on the plastic deformation of the metal to complete, avoiding damage to material properties due to high temperatures.

4. Cut to length:

The formed continuous components are conveyed to the cutting device through a servo feeding system, and are precisely cut by hydraulic or pneumatic cutting knives according to user needs (such as 3 meters, 6 meters/piece). The cutting error can be controlled within ± 1mm, meeting the size requirements of construction.

5. Finished product output:

The cut gutter or downspout is transported to the finished product area by a conveyor belt and can be stacked and stored directly, or combined with subsequent punching, drilling and other auxiliary processes (such as reserved installation holes for downspouts) to form a complete drainage component.