In fields such as architectural decoration, furniture manufacturing, and warehouse shelving, angle steel keel serves as a core component for support, load-bearing, and frame construction. Its processing efficiency and precision directly impact project quality and cost. Angle steel keel machines, as automated equipment specifically designed for angle steel keel production, can rapidly process metal coils or profiles into angle steel keels that meet specific specifications. With their high efficiency, precision, and customizability, they have become essential equipment in the modern metal processing industry.

Basic Definition and Core Functions of Angle Steel Keel Machine

Wall Angle High Speed Rotary Punching Roll Forming Machine, also known as an “angle steel keel forming machine,” is a set of equipment that uses metal coils such as cold-rolled steel plates and galvanized steel plates as raw materials. Through a continuous and automated forming process, it processes the coils into long strip-shaped components with specific cross-sectional shapes (such as L-shaped, U-shaped, etc., suitable for angle steel keel structures). Some models can also be compatible with pre-formed angle steel profiles for further processing such as punching and cutting.

Its core functions mainly include the following three aspects:

1.Continuous forming processing:

Breaking away from the traditional decentralized processing mode of manual cutting and bending, it realizes continuous production from metal coils to formed angle steel keels, greatly improving processing efficiency;

2.Precise specification control:

Strictly following preset dimensional parameters (such as the width, height, thickness, and angle of the keel) to ensure that the finished product dimensional error is controlled within a very small range (usually the width and height error ≤ ±0.5mm, and the angle error ≤ ±0.3°), meeting the installation and load-bearing requirements of different scenarios;

3.Multi-functional integrated processing:

In addition to the basic forming function, most models also integrate functions such as punching, cutting, and straightening, which can complete the drilling of angle steel keels (for subsequent installation and fixing), fixed-length cutting (cutting to the length required by the project), and raw material straightening (correcting the bending deformation caused by the transportation of coils) in one go, realizing “one-stop” processing.

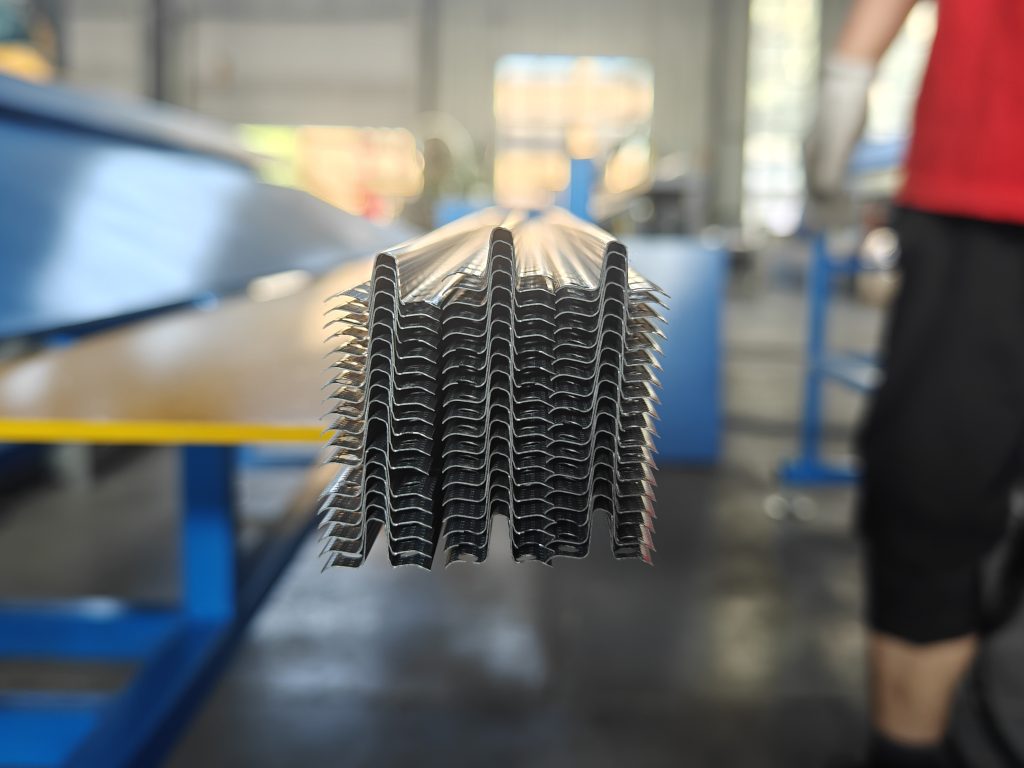

Finished product image:

Main Application Areas

- Architectural Decoration:

Angle steel keel serves as the core support for ceilings, partitions, and other decorative projects, used to fix various panels. Angle steel keel machines can quickly process and customize keels, ensuring the stability and safety of decorative structures in residential and commercial buildings. - Furniture Manufacturing:

In the production of furniture frames such as wardrobes and shelves, the high-precision keels processed by angle steel keel machines can significantly improve component compatibility and production efficiency. - Warehousing and Logistics:

Suitable for warehouses, logistics centers, and other scenarios, it can produce high-strength angle steel keels to meet the load-bearing requirements of light and medium-duty shelves. - Industrial Equipment:

Different specifications of keels can be customized for mechanical equipment frames, operating tables, etc., ensuring the stable operation of industrial equipment. - Agricultural and Livestock Industry:

Mass production of corrosion-resistant galvanized angle steel keels for the construction of facilities such as greenhouses and livestock pens.

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.2-0.3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Punching device

|

Punching type

|

High speed rotary punching

|

||

|

4.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

5.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

6.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

7.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

8.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

9.Forming Speed

|

70m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Machine image: