Omega Metal Track Hat Stud Dryawall Roll Forming Machine

In the field of light steel building materials production, the hat shaped keel, with its unique “hat shaped” cross-sectional structure, has excellent load-bearing capacity and stability, becoming the core component of light steel villa walls, decorative ceilings, partition systems and other scenes. The Omega Metal Track Hat Stud Dryawall Roll Forming Machine, as an automated equipment specialized in producing such keels, provides stable production capacity support for building materials enterprises through standardized and efficient production processes, and is an indispensable key equipment in the modern light steel building materials industry chain.

In practical applications, hat shaped keels have become the core components of light steel villa walls, decorative ceilings, partition systems, and other scenarios. In the field of light steel villa construction, when used as the main keel of the wall, it can be closely combined with insulation and sound insulation materials to construct a composite wall with both high strength and energy-saving characteristics; In commercial space decoration ceiling projects, with the modular assembly characteristics, a flat and stable ceiling frame can be quickly built, greatly reducing the construction period; In the office partition system, its precise dimensional tolerances and reliable connection methods ensure the vertical accuracy and seismic performance of the partition walls.

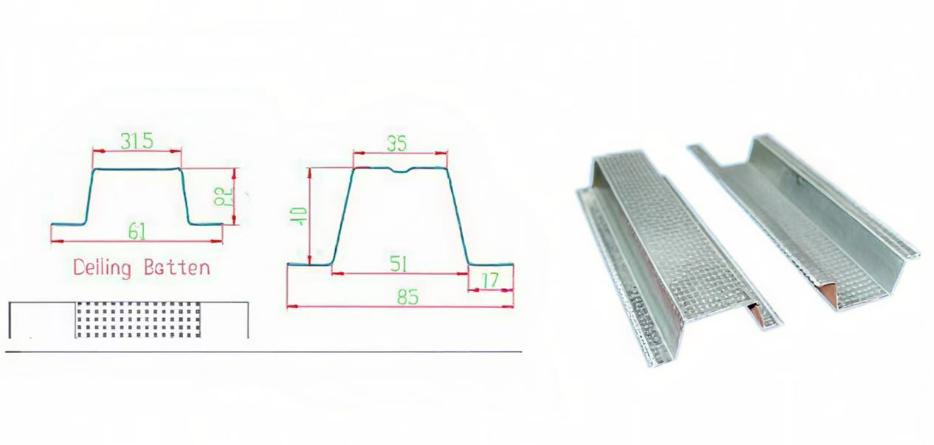

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.4-0.8mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

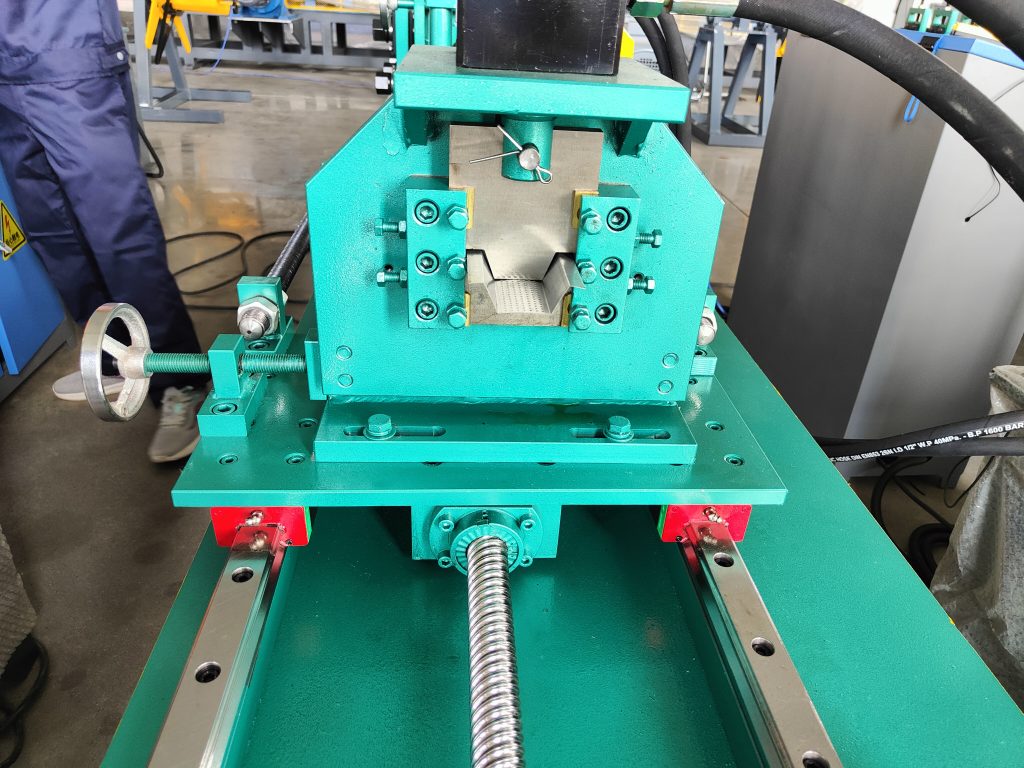

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

40-45m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Machine Core performance characteristics

1. High precision production:

using servo drive and CNC control technology, the forming accuracy can reach ± 0.1mm, the cutting accuracy is ≤± 0.5mm, and the punching position error is ≤ 0.2mm, far higher than industry standards, ensuring the consistency of keel size and reducing adjustment costs during installation;

2. High efficiency output:

The maximum production speed of the equipment can reach 15 meters per minute, and the production capacity can reach 7200 meters under an 8-hour workday, which is 2-3 times that of traditional equipment. It also supports 24-hour continuous operation, effectively shortening the order delivery cycle;

3. Flexible changeover:

Adopting modular mold design and one click changeover system, when changing hat shaped keels of different specifications (such as 50 #, 75 #, 100 #), there is no need to disassemble the mold, only the preset parameters need to be called on the touch screen, and the changeover can be completed in 15-20 minutes, suitable for small batch and multi specification production needs;

4. Low energy consumption:

Equipped with energy-saving motors and intelligent frequency conversion technology, the power is automatically adjusted according to the production speed, and the energy consumption per ton of keel production is reduced by more than 25% compared to traditional equipment; At the same time, automated production reduces reliance on manual labor, requiring only one person to operate a single device, significantly reducing labor costs;

5. Stable and durable:

Key components such as forming rollers and punching molds are made of high-strength alloy materials and undergo special heat treatment, with a service life of over 1 million meters; The overall equipment adopts a steel structure frame, which has strong seismic resistance and can operate stably for a long time with a failure rate of less than 1%;

6. Safe and reliable:

equipped with a fully enclosed protective cover to prevent metal debris from splashing during the production process; Equipped with an emergency stop button and infrared sensing protection device, the equipment will immediately stop when the human body approaches the dangerous area, ensuring the safety of operators.