In modern power transmission and low-voltage signal transmission systems, Cable Tray Punching Machine Sheet Metal Cable Tray Making Machine serves as the core infrastructure for ensuring the safe installation, efficient management, and convenient maintenance of cables. Through standardized structural design, it organizes, supports, and protects scattered cables, widely applied in various scenarios such as industrial plants, commercial buildings, rail transit, data centers, and energy chemical facilities. It is a critical component in building stable and reliable electrical systems.

Core Definition and Functions of the Equipment

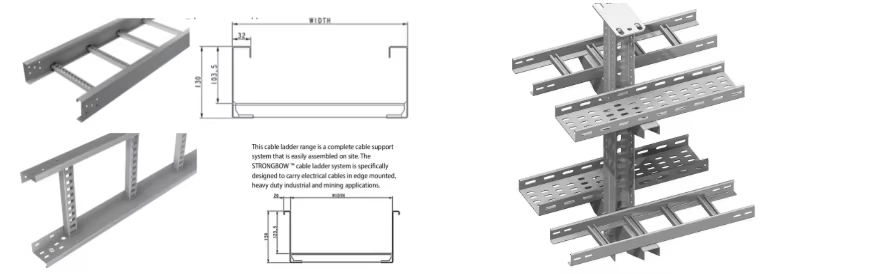

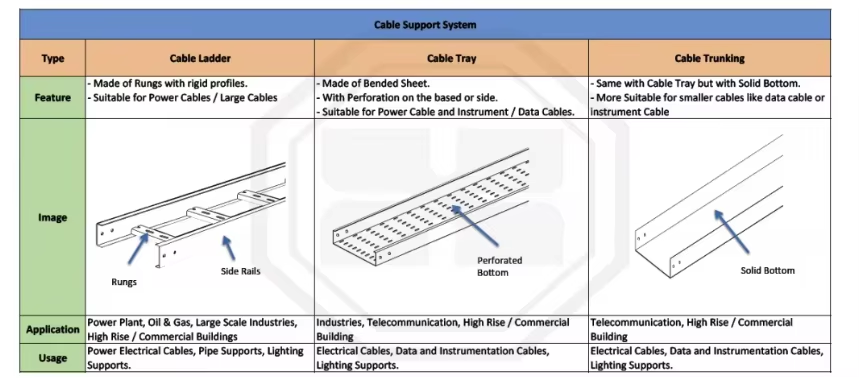

Cable Tray Punching Machine Sheet Metal Cable Tray Making Machine is essentially a rigid structural system made of metal or non-metal materials, designed for supporting and laying cables. It typically consists of the tray body, support components, connecting parts, cover plates, and accessories (such as grounding wires and fireproof sealing materials). Its core functions primarily encompass three key dimensions:

1.Cable Protection:

Effectively isolates dust, moisture, corrosive gases, and mechanical impacts from the external environment, preventing damage to the cable insulation layer, reducing safety hazards such as short circuits and leakage, and extending the service life of the cable;

2.Ordered Management:

Through hierarchical and zonal cable laying design, different types of cables such as power cables, control cables, and communication cables are classified and isolated to prevent signal interference, while significantly improving the neatness of cable layout and providing clear pathways for future maintenance;

3.Flexible Adaptation:

The system can be flexibly adjusted in routing, specifications, and installation methods based on on-site space constraints (e.g., within ceilings, under floors, sidewall mounting, or high-altitude hoisting) and cable quantities, accommodating complex building structures and dynamic expansion needs.

Core performance advantages

1.High installation efficiency:

Modular design enables fast splicing without the need for on-site pouring or complex excavation, and the installation period is shortened by more than 50% compared to cable trenches;

2.Low maintenance cost:

Open or semi open structures facilitate cable maintenance, replacement, and expansion without damaging the original building structure, reducing maintenance costs by 30% -40% in the later stage;

3.Strong safety and stability:

By classifying and isolating the installation, signal interference is reduced, while also possessing fire prevention, corrosion resistance, and impact resistance, reducing the incidence of electrical accidents;

4.High space utilization:

It can be flexibly arranged along walls, ceilings, and columns, making full use of vertical space, especially suitable for high-rise buildings, factories, and other tight space scenarios.

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.7-2.0 mm Width: as request

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

33 rows(As your requirement)

|

||

|

Diameter of shaft

|

90mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

500 H steel

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

15T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW*2 sets,Siemens brand

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||