Solar Panel Mounting Structure Roll Forming Machine

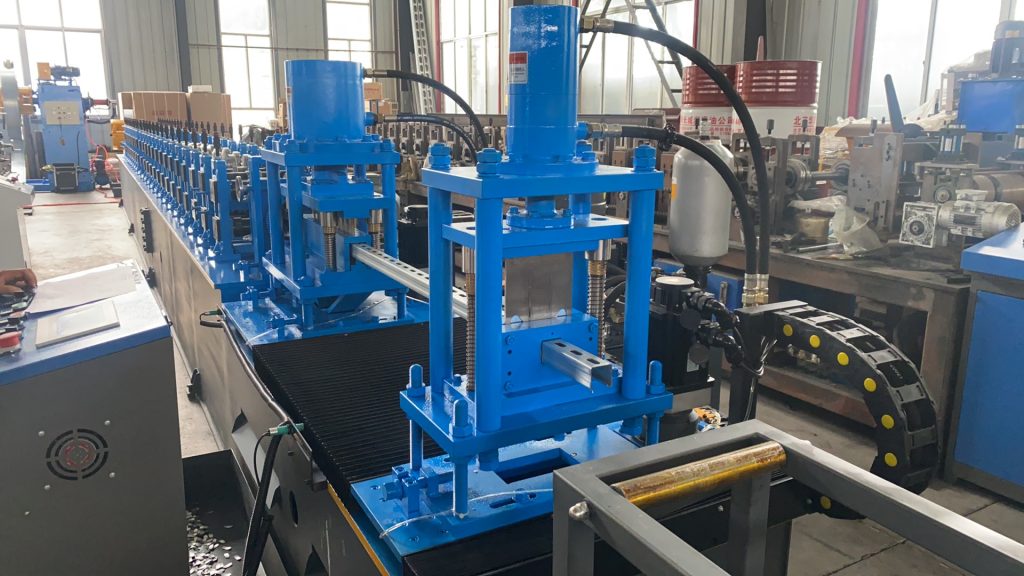

The Solar Panel Mounting Structure Roll Forming Machine is a production equipment specially designed for photovoltaic power station brackets (key structural components supporting solar panels). It is mainly used for integrated processing such as cold bending, punching, and cutting, and can efficiently produce bracket profiles that meet the needs of photovoltaic projects. It is a core equipment in the field of new energy photovoltaic equipment manufacturing and widely serves the production of brackets for ground photovoltaic power stations, roof distributed photovoltaics, agricultural photovoltaic complementary power stations, and other projects.

Applicable scenarios:

1.Large scale ground photovoltaic power station:

suitable for mass production of long specification (6-12 meters) brackets to meet the needs of large-scale construction of power stations;

2.Roof distributed photovoltaics:

can flexibly process short and irregular brackets, suitable for complex spatial layouts on roofs;

3.Photovoltaic bracket manufacturer:

As a core production equipment, it supports the standardization and mass supply of bracket products, and assists manufacturers in undertaking orders for photovoltaic projects of different scales.

Core Features:

1. High adaptability

The mold and parameters can be adjusted according to the requirements of photovoltaic projects (such as bracket materials: galvanized steel, aluminum alloy; bracket types: fixed, single axis tracking, double axis tracking), covering more than 90% of photovoltaic bracket specifications without the need to replace the entire equipment, reducing production investment.

2. Efficient and stable

The processing speed of the fully automated production line can reach 15-20 meters per minute, and the daily production capacity can meet the support requirements of 500-800 square meters of photovoltaic power plants; The body is made of high-strength steel and precision servo system, with a continuous operation failure rate of less than 0.3%, ensuring the continuity of mass production.

3. Accurately meet the standards

The precision control of the entire process of forming, punching, and cutting is strict, and the produced bracket profiles can meet the requirements of the photovoltaic industry for load-bearing (wind resistance, snow resistance) and anti-corrosion (adaptation to harsh outdoor environments), avoiding installation delays or safety hazards caused by insufficient bracket precision in power plants.

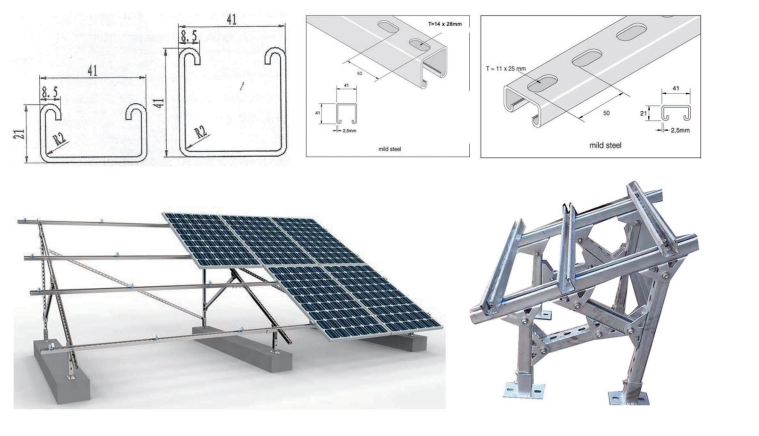

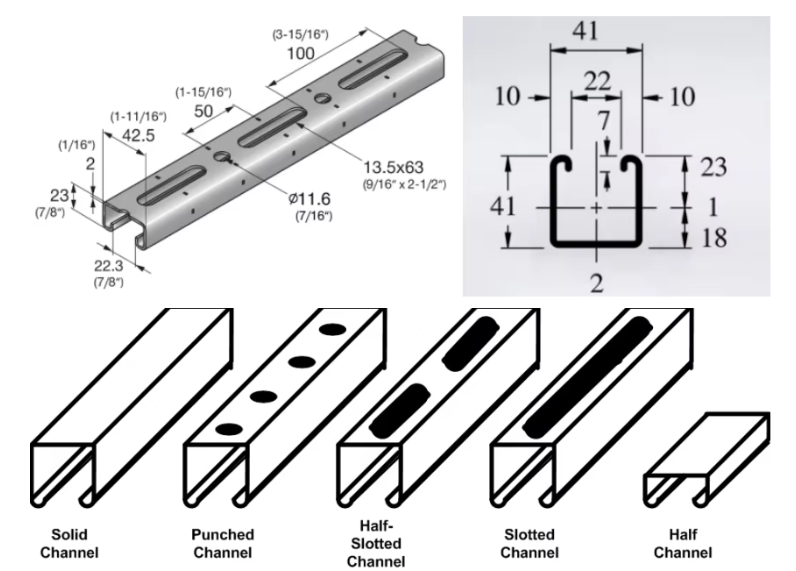

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.5-2.0mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

14 rows(As your requirement)

|

||

|

Diameter of shaft

|

60mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

chain transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW

|

||

|

Hydraulic system power

|

11KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

70m/min(customized)

|

Speed is adjustable according to customer’s request

|

||