Are you still worried about the production capacity of dragon bones being unable to keep up with the schedule, the proportion of labor being too high, and the difficulty of switching specifications? Don’t worry! The dual unit keel machine is here – integrating “dual line parallel, intelligent speed control, and multi adaptability”, allowing one device to play the value of two single machines, helping you easily break through production bottlenecks and seize industry dividends!

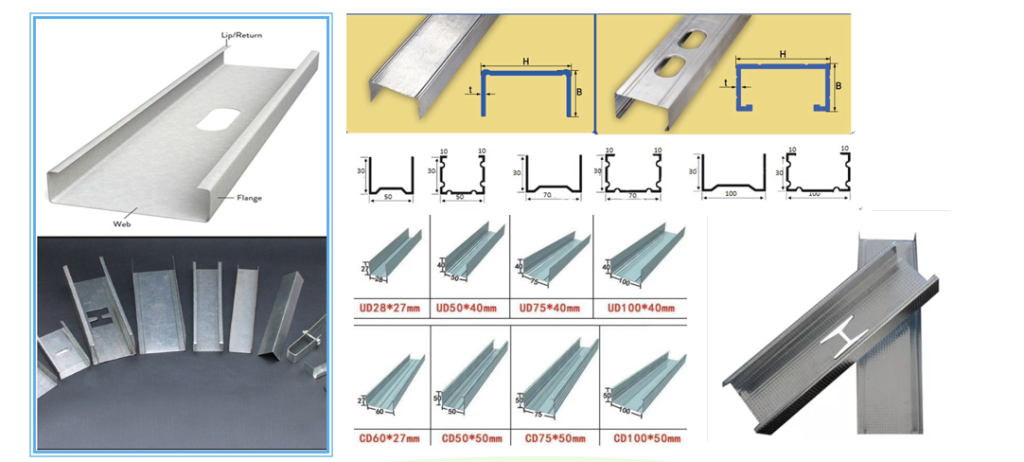

Pattern diagram:

Product Attributes :

| 1.Formed Material | PPGI,GI,AI | Thickness:0.5-1.2mm | ||

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) | ||

| 3.Main body | Roller station | 12 rows(As your requirement) | ||

| Diameter of shaft | 50mm solid shaft | |||

| Material of rollers | 45# steel, hard chrome plated on the surface | |||

| Machine body frame | Metal steel welded | |||

| Drive | gearbox transmission | |||

| Dimension(L*W*H) | 5500*800*1200(customize) | |||

| Weight | About 3T | |||

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation | ||

| 5.Power | Motor Power | 7.5KW | ||

| Hydraulic system power | 5.5KW | |||

| 6.Voltage | 380V 50Hz 3Phase | As your requirement | ||

| 7.Control system | Electric Box | Customized(famous brand) | ||

| Language | English(Support multiple languages) | |||

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |||

| 18.Forming Speed | 60-70m/min(customized) | The speed depends on the shape of the tile and the thickness of the material. | ||

Why is it called a ‘cost reducing and efficiency enhancing tool’? 3 core advantages directly targeting pain points

1. Doubling efficiency, no longer dragging down the project schedule

The traditional single machine can produce up to 20 tons of keel per zenith, but when it comes to large-scale projects, they often have to work late into the night. The dual unit keel machine is equipped with dual independent forming production lines, which can directly double the production capacity during synchronous operation! Taking the Shanghai Wohua dual servo model as an example: under no punching conditions, the speed can reach 120 meters per minute, and one production line can produce 30 tons in one day. The monthly production capacity of two parallel lines can easily exceed 600 tons – three times faster than traditional equipment. The original 30 day construction period can now be completed in 10 days!

More considerate is the “quick change” design: traditional equipment requires dismantling rollers and adjusting parameters to change specifications, which can easily lead to errors even after 2 hours of tinkering; The dual unit relies on a fully automatic changeover system, which can switch between C-type, U-type, T-type and other specifications in 10 minutes. Even if it accepts orders for three different projects at the same time, it can flexibly respond without delaying work.

2. Save space and labor, reduce costs by 50% directly

Buying 2 single machines requires a 20 square meter workshop and 4 workers? The dual unit integrates two production lines on one rack, saving 30% of the floor space and allowing for easy installation in small workshops; And the entire process is automated – from unwinding, forming to cutting, 1-2 workers can manage the entire line, reducing labor costs by half!

Not to mention ‘material saving’: the servo cutting system has a cutting error of ≤ 0.5mm, and the cumulative error of the 16 meter long column is only ± 1mm. The material utilization rate exceeds 95%, and there is no need to worry about the cost of ‘too much waste’ anymore.

3. The accuracy is stable enough and the adaptability is wide enough, with one unit used for up to N units

Whether it’s the 50mm national standard secondary keel for building ceilings, the 200mm C-shaped steel purlins for factory steel structures, or even the YX50 beam for agricultural greenhouses and the irregular frame for photovoltaic projects – the dual unit keel machine can “set N sets on top of one machine”! Taking the Dahe Zhongbang MF6S2000 model as an example, it is compatible with various specifications ranging from 89-200mm, from low rise residential buildings to 6-story light steel experimental buildings (such as the Chongqing University project), from domestic decoration to Singapore seismic bracket exports, all of which can accurately match the needs.

And the quality is hard enough: 45 # round steel spindle+GCr15 quenching mold, shear blade life exceeds 1 million times; Each device undergoes 12 quality inspections with a pass rate of ≥ 99.8%, and has also passed certifications such as ISO9001, CE, UL, etc. It is exported to more than 20 countries worldwide without fear of “card standards”.