https://www.youtube.com/watch?v=T2hRPY_aZk4

High-Performance Two Waves Highway Guardrail Roll Forming Machine in Road Construction

Highway guardrail roll forming machines stand as pivotal equipment in the manufacturing of road safety facilities, engineered to transform metal sheets into corrugated guardrail panels that adhere to national standards. They find extensive application in safety protection projects across highways, first-class roads, and key urban-rural thoroughfares. Leveraging automated and continuous roll forming techniques, these machines enable the efficient conversion of raw materials into finished guardrail panels, thus fortifying road traffic safety.

Key Components and Technical Nuances of Highway Guardrail Roll Forming Machine

The design of highway guardrail roll forming machines is rooted in the pursuit of “high precision, efficiency, and stability,” comprising the following essential parts:

– Uncoiling and Feeding System:

A heavy-duty uncoiler takes center stage here, capable of holding coil steel strips weighing several tons—typically crafted from Q235 low-carbon steel or galvanized sheets. A tension control mechanism ensures steady uncoiling, preventing processing inaccuracies caused by loose raw materials. The feeding unit, powered by a servo motor, achieves a feeding precision of ±0.1mm, keeping the steel strip steady during the forming process.

– Leveling and Pretreatment Unit:

To tackle issues like bending and warping in coiled steel strips, the leveler employs multiple sets of leveling rolls for “gradual correction.” This ensures the raw material’s flatness error stays within ≤0.5mm/m, laying a solid groundwork for subsequent forming accuracy. Some advanced models integrate surface pretreatment features, removing oil stains and oxide scales from the steel strip’s surface to boost the adhesion of later galvanizing or plastic coating.

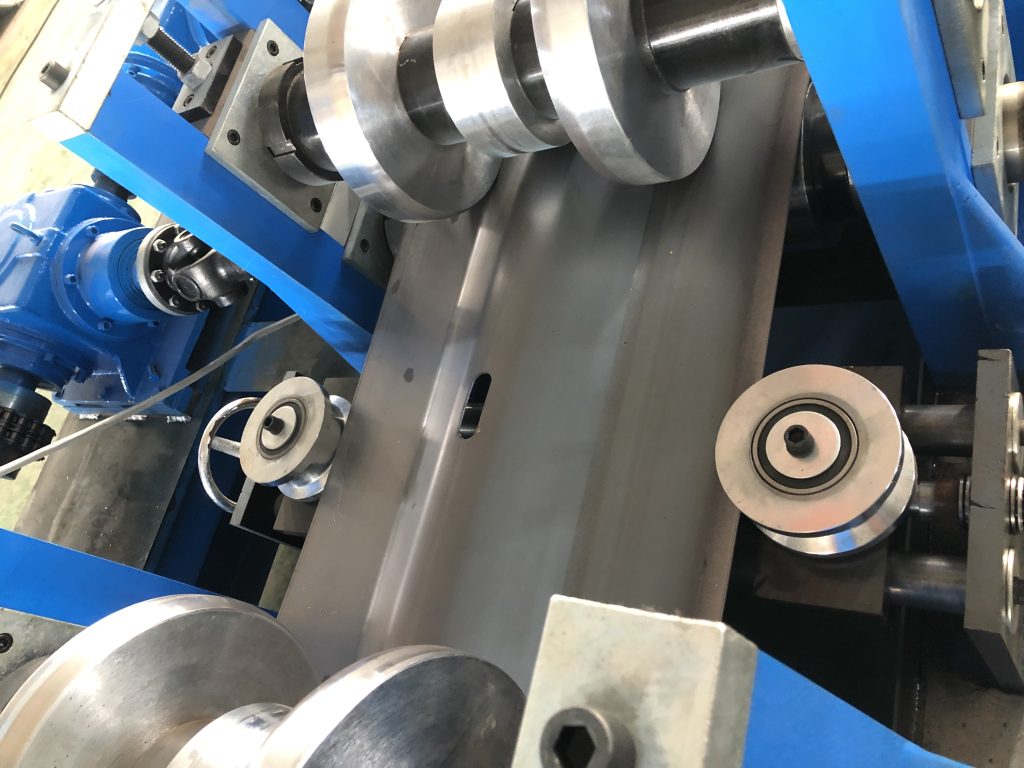

– Roll Forming Mainframe:

As the core processing component, it consists of 15-25 sets of forming rolls (the count varies with guardrail panel specifications). Each roll’s contour is segmentally designed based on the guardrail’s corrugated curve. Made from high-hardness alloy steel such as Cr12MoV, these rolls undergo quenching to reach a hardness of HRC58-62, ensuring resistance to wear under prolonged high-pressure operation. During processing, the steel strip passes through the roll sets, undergoing “initial bending → corrugation shaping → finishing and setting” to form standard corrugations—for instance, the “W” shape of two-wave guardrails (85mm wave height, 310mm width) or the composite shape of three-wave ones (506mm total width).

– Punching and Cutting Mechanism:

The punching unit, driven hydraulically, comes with high-precision molds to drill 18-22mm diameter connection holes at designated positions on the guardrail. Hole position deviation is limited to ±0.3mm, guaranteeing a precise fit with columns and brackets during installation. The cutting device, choosing between hydraulic shears or circular saws, operates swiftly (single cut ≤1 second) with clean, burr-free edges, eliminating the need for post-cut grinding.

– Control System and Smart Features:

A PLC programmable control system, paired with a 10-15 inch touchscreen, allows for easy setting of parameters like forming speed (3-15m/min adjustable), cutting length (3-6m for common sizes), and number of punch holes. It can store over 100 process recipes, avoiding repeated debugging when switching between guardrail specifications. Some machines also feature intelligent monitoring, using sensors to track forming pressure and steel strip thickness deviations, triggering an immediate shutdown and alarm in case of anomalies to minimize waste.

Production Process and Technological Benefits

The manufacturing flow of highway guardrail roll forming machines is a fully automated closed-loop system, with steps as follows:

1. Raw Material Loading: The coiled steel strip is hoisted onto the uncoiler, manually guided through the leveler, and positioned initially.

2. Pretreatment and Leveling: The steel strip is leveled to relieve stress, while the surface pretreatment device cleans it simultaneously.

3. Continuous Roll Forming: The steel strip enters the mainframe, gradually taking shape into the preset corrugation under the rolls’ action, with infrared monitoring ensuring dimensional compliance.

4. Punching and Cutting: The formed continuous guardrail is punched with mounting holes and then cut to the set length.

5. Finished Product Discharge: Cut guardrail panels are conveyed to the stacking rack via a conveyor belt, completing one production cycle.

Main roll forming machine of Highway Guardrail Roll Forming Machine

| Roller station | 16 rows(As your requirement) | ||

| Diameter of shaft | φ95mm | ||

| Material of rollers | 45# steel with tempering | ||

| Machine body frame | 400 H steel | ||

| Drive | Gearbox transmission | ||

| Dimension(L*W*H) | 18500*1200*1500mm | ||

| Weight | 15T |

Compared to traditional welding or stamping, its key advantages of Highway Guardrail Roll Forming Machine

– High Material Utilization: Cold roll forming avoids excess material cutting, achieving a raw material utilization rate of over 95%—far higher than the 70%-80% of stamping.

– Enhanced Mechanical Properties: Cold working refines the steel’s internal grains, increasing the guardrail’s tensile strength by 10%-15% and significantly improving impact resistance.

– Stable Efficiency: Under continuous production, a single machine can produce 500-800 meters daily, with consistent product quality (dimensional error ≤1mm).

Application Scopes and Industry Norms

Guardrail panels produced by these machines are core to road safety systems, used primarily in:

– Central dividers and edges of highways and first-class roads;

– High-risk areas like mountain roads and bridge approaches;

– Perimeter protection of large industrial parks and logistics centers.

Products must strictly meet standards such as GB/T 31439-2015 “Road Corrugated Beam Steel Guardrails”. For example, two-wave guardrails must weigh ≥49.1kg per meter, three-wave ones ≥102kg per meter, and have a galvanized layer thickness ≥85μm. This ensures they can absorb impact energy, guide vehicles, and reduce casualties in collisions.

Maintenance and Selection Tips of Highway Guardrail Roll Forming Machine

For long-term stable operation, regular maintenance is crucial:

– Inspect forming rolls for wear every 5,000 meters produced, grinding and repairing them promptly.

– Replace hydraulic system filters monthly to prevent pipeline blockages from oil impurities.

– Calibrate control system parameters quarterly to maintain sensor accuracy.

When selecting a machine, consider:

– Opt for two-wave/three-wave dedicated models or multi-functional ones (supporting production switching) based on needs.

– Prioritize equipment with servo feeding and intelligent monitoring to cut labor costs.

– Ensure compatibility with different steel strip thicknesses (3-4mm commonly used) to handle diverse orders.

Highway guardrail roll forming machines, with their precise process control and efficient production, form the backbone of the road safety facilities industry. Their performance directly impacts guardrail quality, which in turn safeguards the lives of countless road users.