In the field of modern horticulture, innovation and efficiency are key to enhancing the horticultural experience and results. The metal raised garden bed roll forming machine, as a breakthrough technology, is gradually changing the way people create gardens. It not only provides efficient and convenient solutions for gardening enthusiasts, but also brings unprecedented creative possibilities for professional horticulturists.

1. Efficient production, saving time and costs:

The metal raised garden bed roll forming machine stands out for its excellent production efficiency. The traditional method of making garden beds often requires a lot of manual operation and time investment, from cutting, bending to assembly, each step may consume a lot of energy. And this roll forming machine can quickly process metal sheets into the desired garden bed shape through advanced automation technology. Whether it is a simple rectangle or a complex curved design, it can easily handle it, greatly shortening the production cycle and saving labor costs.

Taking the production of a standard sized metal raised garden bed as an example, traditional handmade production may take several hours or even a whole day, while using a roll forming machine can be completed in just a few tens of minutes, increasing efficiency several times. This means that gardening enthusiasts can create their ideal gardens in a shorter amount of time, and professional horticulturists can undertake more projects and increase business volume.

2. High precision machining to ensure consistent quality:

In addition to efficiency, the processing accuracy of the roll forming machine is also a major highlight. It adopts precision rollers and advanced control system, which can accurately control the bending angle and size of metal sheets, ensuring that the production accuracy of each garden bed can reach extremely high standards. This high precision not only ensures the beauty of the garden bed, but also enhances its structural stability and durability.

Compared to the size deviation and irregular shape that may occur in handmade production, garden beds produced by roll forming machines have a high degree of consistency. Every garden bed seems to be carved from the same mold, whether used for private courtyards or commercial landscape projects, it can showcase a professional and exquisite effect. Moreover, due to high processing accuracy, the assembly of garden beds is also easier, reducing installation difficulties caused by size mismatch.

3. Diverse designs to meet personalized needs:

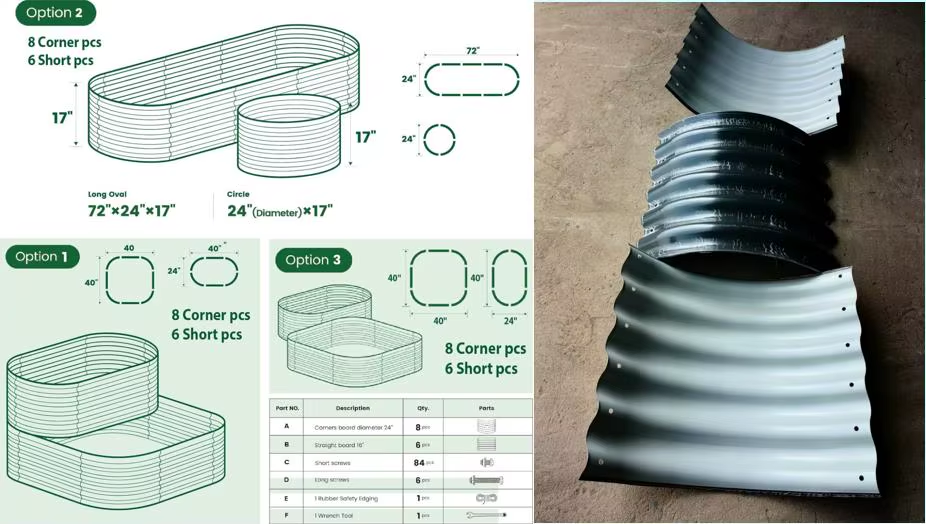

Modern horticulture emphasizes personalization and creativity, and the metal raised garden bed roll forming machine provides strong support for this demand. It can process metal sheets into various unique shapes and styles according to user design requirements. Whether it is a circular, elliptical, wavy or customized irregular shape, it can be easily achieved through a roll forming machine.

Horticultural enthusiasts can customize unique garden beds according to their own courtyard style and personal preferences. Professional horticulturists can also utilize the flexibility of the rolling machine to boldly innovate in landscape design and create eye-catching characteristic gardens. This diverse design capability makes the metal raised garden bed a beautiful landscape in the garden, adding infinite possibilities to horticultural creation.

4. Durable materials create long-lasting garden landscapes:

The metal raised garden bed roll forming machine is usually processed using durable materials such as galvanized steel plates. These materials have excellent rust and corrosion resistance, and can maintain good condition in various harsh outdoor environments. Compared with traditional wooden garden beds, metal garden beds are more sturdy and durable, less susceptible to factors such as pests and moisture, and have a greatly extended service life.

The metal garden bed made by the roll forming machine not only provides a stable growth environment for plants, but also maintains its beauty for a long time, reducing the cost of maintenance and replacement in the later stage. Whether in the sunny south or the cold and humid north, metal garden beds can withstand the test of time and create long-lasting beautiful garden landscapes for you.

5. Environmental protection and energy conservation, in line with modern concepts:

While pursuing efficiency and aesthetics, the metal raised garden bed roll forming machine also fully considers the needs of environmental protection and energy conservation. It has low energy consumption in the production process, and due to the use of metal materials, it can be recycled and reused, which meets the requirements of modern society for environmentally friendly products. Compared with some traditional garden bed making materials, the use of metal materials reduces the consumption of natural resources such as wood, which helps to protect the ecological environment.

Choosing a metal raised garden bed roll forming machine is not only an efficient and high-quality way of making garden beds, but also an environmentally friendly and sustainable lifestyle concept. It not only creates beautiful gardens for us, but also contributes to the future of the earth.

The metal raised garden bed roll forming machine has become an ideal choice in the field of horticulture due to its high efficiency, precision, diversity, durability, and environmental friendliness. Both individual gardening enthusiasts and professional landscape designers and gardening contractors can benefit greatly from this innovative device. If you are planning to create a beautiful garden, you may consider introducing a metal raised garden bed roll forming machine to start your horticultural innovation journey and make your garden shine with unique charm.