C Z Purlin Roll Forming Machine,In modern architecture and manufacturing, steel sections, as an important structural material, are widely used in various fields. To meet the ever-growing market demand and improve the production efficiency and quality of steel sections, fully automatic C Z Purlin Roll Forming Machines have emerged. This advanced equipment, characterized by its automation, high precision, and high efficiency, has become a capable assistant for steel section production enterprises.

Product Attributes of C Z Purlin Roll Forming Machine:

|

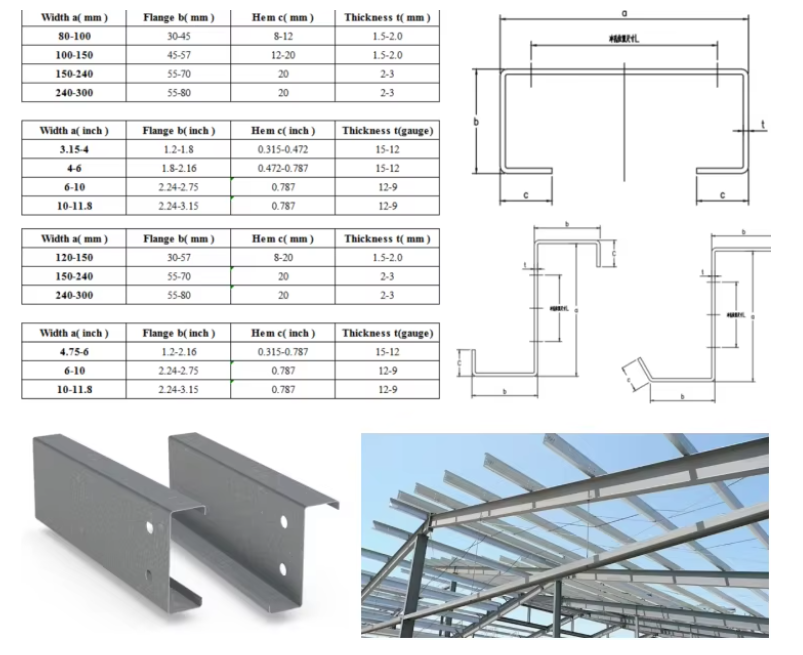

1.Formed Material

|

GI

|

Thickness:1.5-3 mm (standard)

|

||

|

2.Decoiler

|

3 Tons Hydraulic automatic decoiler

|

3 Tons Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

20 rows (As your requirement)

|

||

|

Diameter of shaft

|

80 mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gear and chains transmission

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

15T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW*2 sets,Siemens brand

|

||

|

Hydraulic system power

|

15 KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

25 m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

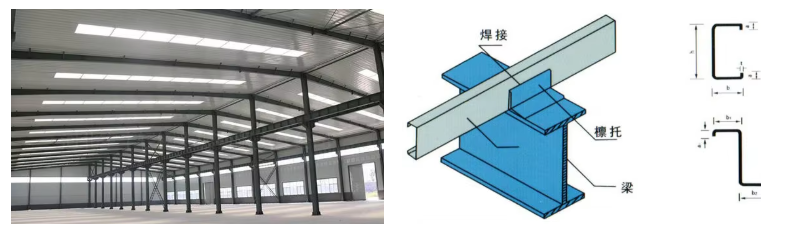

Widely applicable scenarios

1.Construction industry:

In the field of construction, CZ steel is widely used in the roof and wall purlins of steel structure buildings. The fully automatic C Z Purlin Roll Forming Machine can produce various specifications of C-type and Z-type purlins to meet the needs of different building designs. Its high-precision processing quality ensures the accuracy and stability of purlins during installation, improving the overall safety and reliability of building structures.

2.Manufacturing industry:

In industries such as machinery manufacturing and automobile manufacturing, CZ steel is often used to make equipment frames, support structures, etc. The steel produced by the fully automatic C Z Purlin Roll Forming Machine has good strength and accuracy, which can meet the manufacturing industry’s requirements for high-precision and high-quality components. At the same time, the efficient production capacity of the equipment can provide sufficient raw material supply for manufacturing enterprises, improve their production efficiency and market competitiveness.

3.Storage and logistics:

Storage shelves are important facilities in the storage and logistics industry. CZ steel, as the main structural material of shelves, directly affects their load-bearing capacity and stability in terms of quality and specifications. The fully automatic CZ steel machine can produce customized C-shaped and Z-shaped steel according to the design requirements of storage shelves, providing reliable material guarantee for the warehousing and logistics industry.

Working principle revealed

The working principle of the fully automatic C Z Purlin Roll Forming Machine is based on advanced automation control technology and precise mechanical structure. The main workflow is as follows:

1. Feeding system: Firstly, the raw materials (usually steel strips or steel coils) are placed on the feeding rack. The feeding system is driven by a motor to smoothly feed raw materials into the equipment, ensuring the stability of feeding speed and accuracy.

2. Molding system: After entering the molding system, the raw materials undergo a series of carefully designed molding molds. These molds gradually bend and shape the raw materials according to the preset specifications of C-shaped or Z-shaped steel. The forming process is achieved through the collaborative action of multiple sets of rollers, and the spacing and shape of the rollers are accurately calculated to ensure the dimensional accuracy and surface quality of the steel section.

3. Punching and cutting system: During the formation of the steel section, the punching device performs punching operations on the steel section according to the set hole position and aperture requirements. This process usually uses hydraulic or pneumatic driven punches, which can quickly and accurately complete punching tasks. When the steel reaches the set length, the cutting system starts, and the high-speed cutting tool cuts the steel to ensure a smooth and flat cutting surface.

4. Collection and organization system: The formed and cut CZ steel is transported to the collection area. The collection system can automatically stack or classify according to needs, facilitating subsequent handling and storage. The entire work process is precisely monitored and adjusted by a computer control system. Operators only need to input the corresponding parameters on the control interface, and the equipment can automatically run according to the set program.

Technical feature display

1.High degree of automation:

The fully automatic C Z Purlin Roll Forming Machine realizes the full process automation operation from raw material feeding, forming, punching, cutting to finished product collection, greatly reducing manual intervention, lowering labor intensity, and improving production efficiency. Operators only need to set parameters and debug the equipment before operation, and the equipment can run continuously and stably, producing steel products that meet the requirements.

2.High precision machining:

Through advanced CNC technology and precise mechanical structures, the equipment can ensure the dimensional accuracy and surface quality of the steel section. During the forming process, the high-precision machining of the rollers and the precise positioning system enable the dimensional deviation of the steel to be controlled within a very small range. The precision of punching and cutting can also meet various high standard engineering requirements, ensuring the quality stability of steel products.

3.Quick changeover:

In order to meet the market demand for different specifications of CZ steel, the equipment has a quick changeover function. The operator only needs to input the new specifications of the steel in the control system, and the equipment can automatically adjust the position and parameters of the forming mold, punching mold, and cutting tool, achieving rapid switching of production of different specifications of steel, greatly reducing production preparation time, and improving the production flexibility of the equipment.

4.Efficient and energy-saving:

The equipment is designed with full consideration of energy utilization efficiency, using energy-saving motors and advanced transmission systems to reduce energy consumption. Meanwhile, the efficient production process and fast processing speed significantly increase the output per unit time, further improving energy utilization efficiency and reducing production costs.