C Z Purlin Cold Roll Forming

https://www.youtube.com/watch?v=zVpxDTzz9pE

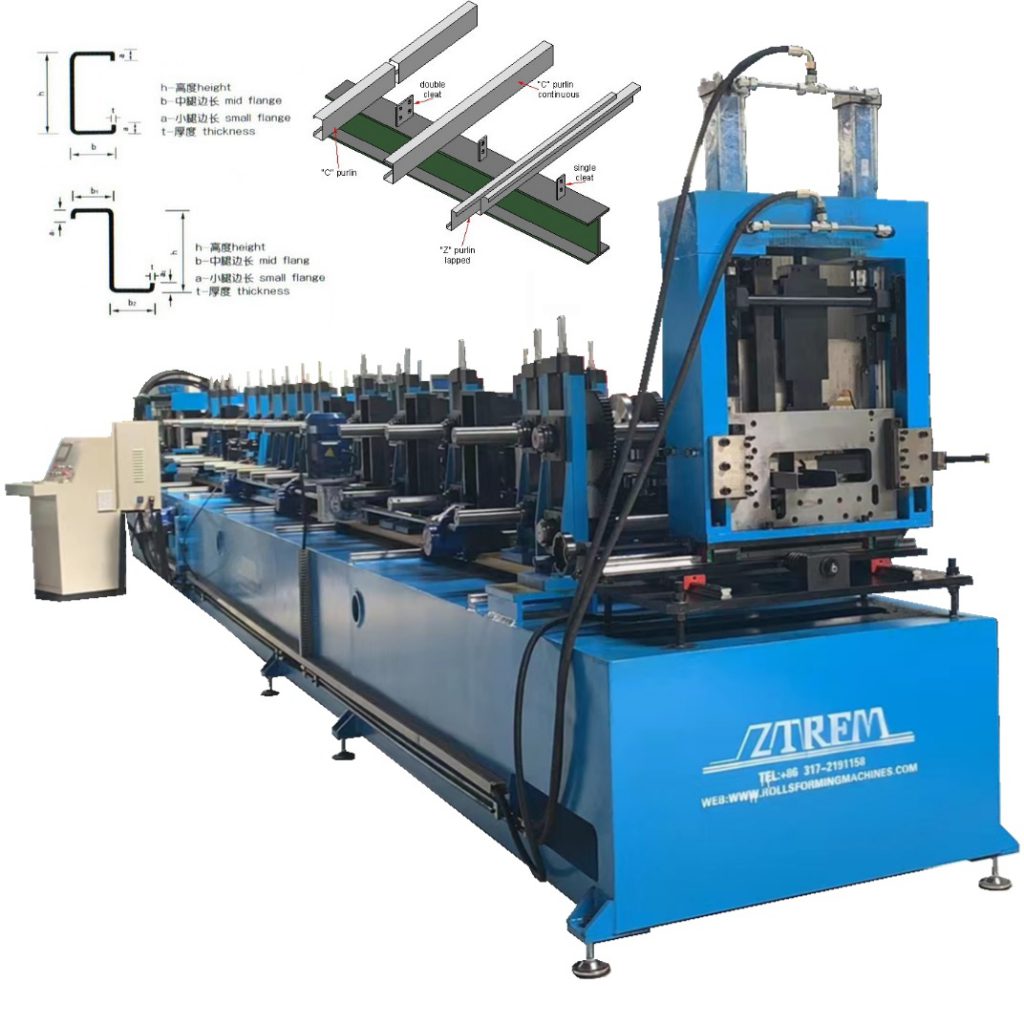

In the fields of modern industrial and technological production, automated machinery has become a core pillar for improving efficiency, ensuring safety, and optimizing quality. The fully automatic CZ interchangeable purlin machine is a typical example under this trend. With its highly integrated design and intelligent control, it demonstrates significant advantages in the field of section steel processing, and its unique features also bring many innovations to the production process. The following will elaborate on its advantages and features in detail.

Core Advantages of the Fully Automatic CZ Interchangeable Purlin Machine

As an intelligent equipment integrating the processing functions of C Z purlin, the fully automatic CZ interchangeable purlin machine (also known as CZ purlin all-in-one machine) has its core advantage in breaking the limitations of traditional processing modes. It realizes highly automated operation through the PLC computer control system, enabling quick switching between C-type and Z-type purlins in a short time and supporting flexible adjustment of various specifications. This means that it can continuously produce purlins of different models without repeated manual debugging, greatly reducing the downtime during specification conversion and fundamentally improving the continuity and efficiency of the production line.

More importantly, this equipment has completely changed the traditional mode of configuring separate C-type and Z-type machines in the past. In traditional processing, the two types of machines not only occupy a large amount of space but also require repeated investment in equipment costs. However, the fully automatic CZ interchangeable purlin machine, with its integrated design, saves equipment investment and significantly reduces the production floor space, lowering the space and capital costs for enterprises.

In addition, its automation degree runs through the entire production process: key parameters such as the input length, production quantity, and longitudinal hole spacing of purlins can be automatically executed through system presets without manual adjustment for each piece; the processing precision of stamped holes is extremely high, with errors controlled within a very small range, ensuring product consistency; the equipment operates stably and reliably, and with efficient power output, it can achieve high output while ensuring quality, providing users with full-process convenience from parameter setting to finished product output.

Main parameters of the C Z purlin machine

|

1.Formed Material

|

GI

|

Thickness:1.5-3 mm (standard)

|

||

|

2.Decoiler

|

3 Tons Hydraulic automatic decoiler

|

3 Tons Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

20 rows (As your requirement)

|

||

|

Diameter of shaft

|

80 mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gear and chains transmission

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

15T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW*2 sets,Siemens brand

|

||

|

Hydraulic system power

|

15 KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

25 m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Distinctive Features of the Fully Automatic C Z Purlin Machine

From product performance to equipment design, the features of the fully automatic C Z purlin machine fully reflect the combination of intelligence and practicality. Taking the equipment produced by Zhejiang Jinggong as an example, the C Z purlin processed by it have excellent flatness, strong structural stability, and outstanding compressive and bending resistance, which can meet the needs of various load-bearing scenarios; the Z-type purlins support reverse lap installation, and through optimizing the design of connection points, the installation strength is greatly improved, making them suitable for engineering scenarios with higher requirements for structural stability.

In terms of the control system, the equipment is equipped with a fully automatic electrical system integrated with an intelligent error reporting function. When problems such as parameter abnormalities or insufficient material supply occur during production, the system will alarm in real-time and stop operation, effectively avoiding batch defective products or equipment damage caused by faults, and providing double guarantees for the safe and stable operation of the production line. The drive system adopts a combination of a reduction motor and frequency conversion control, which can not only precisely regulate the production speed but also ensure the accuracy of fixed-length positioning, controlling the dimensional error of each purlin within strict standards.

The most prominent feature lies in its design of “converting profiles without changing forming rolls”. When traditional equipment switches between CZ purlin, it is necessary to disassemble and replace the forming rolls, which is time-consuming and laborious and may affect precision. However, this equipment can realize the rapid conversion of C Z models by virtue of its ingenious mechanical structure design, combined with partial manual rotation of fixed components (such as rotating plates). The whole process takes little time and is easy to operate, greatly improving production flexibility and truly realizing the core value of “one machine with multiple uses and efficient conversion”.

In summary, the fully automatic CZ interchangeable purlin machine, with its advantages in automated integration, cost optimization, and precision control, as well as features such as flexible conversion, stability and reliability, and strong adaptability, has become an efficient solution in the field of modern section steel processing, providing strong support for the intelligent upgrading of industrial production.

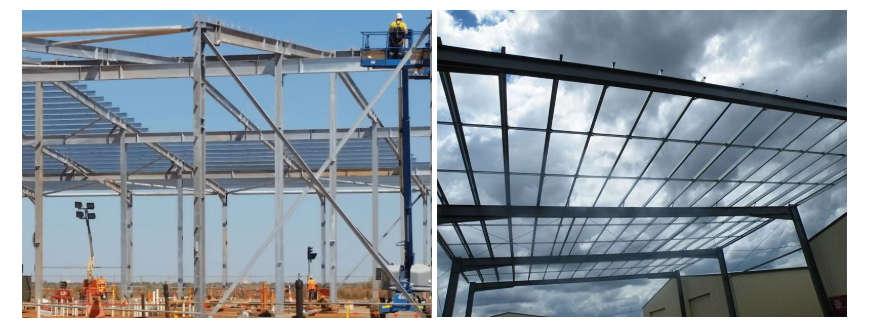

Application of C Z purlin

Recommend related machine