In today’s booming construction industry, roofing material processing equipment is also constantly innovating. As a professional roofing tile processing equipment, trapezoidal roofing tile machine is becoming the first choice for many construction enterprises, roofing contractors and building materials processing factories with its excellent performance and efficient production capacity.

Product Attributes :

|

1.Formed Material

|

PPGI,PPGL

|

Material Thickness:24/26 Gauge (0.3-0.8 mm)

Width:43inch(1092mm)

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

Manual decoiler(will give you as free)

|

||

|

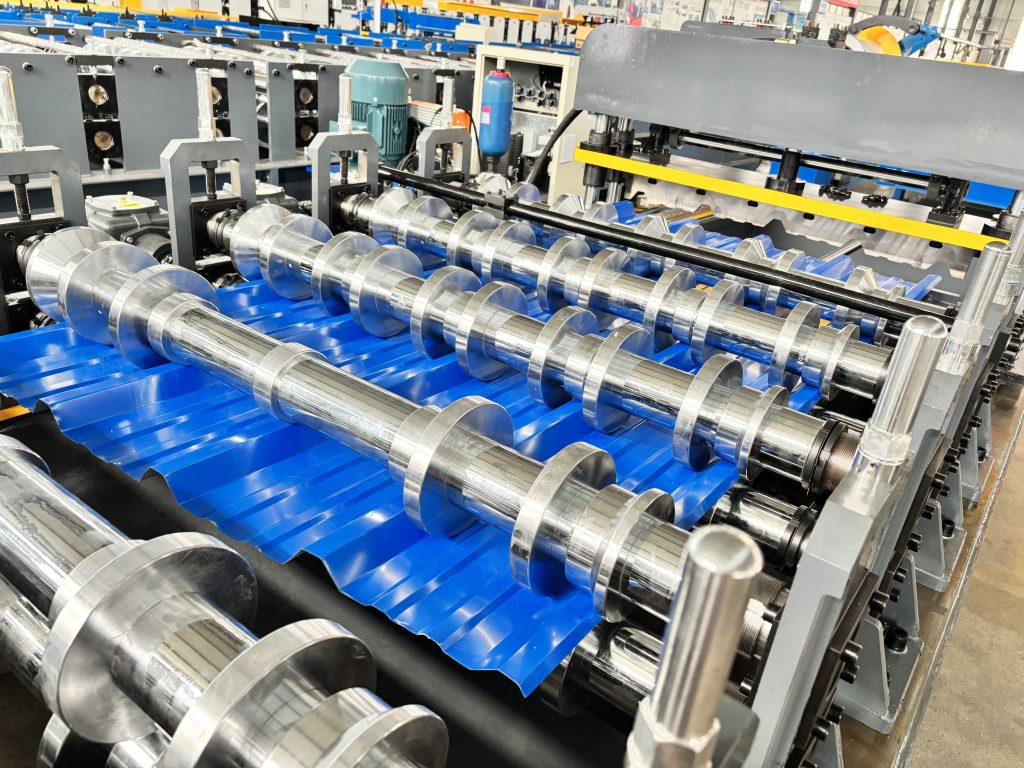

3.Main body

|

Roller station

|

18 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

350mm H Beam Structure, With 18mm Welded Steel Middle Support Plate.

|

|||

|

Drive

|

gear and Double Chain transmission

|

|||

|

Dimension(L*W*H)

|

9.5m*1.65m*1.5m

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

4.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

Excellent performance:

1.Efficient automated production:

The trapezoidal roofing tile machine adopts an advanced automation control system, which can achieve continuous production and greatly improve production efficiency. From the feeding and forming of raw materials to the cutting and stacking of finished products, the whole process is completed in one go, which effectively reduces manual intervention, reduces labor intensity, and also ensures the stability of product quality. Compared with traditional handmade or semi-automated equipment, the production speed of trapezoidal roofing tile machine can be increased several times or even dozens of times, which can meet the urgent needs of large-scale engineering projects.

2.High-precision molding process:

Through precise mold design and advanced pressing technology, the equipment can accurately process raw materials such as sheet metals and synthetic resins into various specifications of trapezoidal roofing tiles. The high dimensional accuracy of the tiles, good surface flatness, and regular corrugated shape not only enhance the waterproof performance of the roof, but also improve the overall aesthetics of the building. Whether it’s standard roof tiles or special-shaped tiles tailored to special architectural design requirements, trapezoidal roof tiles can be easily handled, providing architectural designers with a broad creative space.

3.Wide Material Adaptability:

The trapezoidal roof tile tile machine is suitable for a wide range of raw materials, including galvanized steel sheets, color-coated steel plates, aluminum-zinc coated steel, synthetic resins, and more. Different materials have their own unique properties, such as galvanized steel plates have good corrosion resistance, color-coated steel plates are rich in color and strong decoration, and synthetic resins have the advantages of light weight, sound insulation, and heat insulation. Users can flexibly choose the appropriate raw materials according to the actual needs and budget of the project, and the trapezoidal roofing tile machine can process it into high-quality roofing tile products to meet the needs of different construction scenarios.

Diversified application fields:

1.Industrial Buildings:

In industrial buildings such as industrial plants and warehouses, trapezoidal roofing tiles are ideal for roofing covering materials due to their good waterproof, fireproof, and corrosion resistance properties, as well as high strength. The trapezoidal roof tile machine can produce tile types suitable for the needs of large-span and large-area roofs of industrial buildings, with convenient installation and short construction period, which can effectively reduce the construction cost of industrial buildings. At the same time, its diverse colors and appearance designs can also make industrial buildings meet functional needs while having a certain aesthetics.

2.Civil buildings:

Whether it is residential communities, villas, or public buildings such as schools and hospitals, trapezoidal roof tiles can add a unique charm to them. In civil buildings, the aesthetics and durability of roof tiles are particularly important. The roofing tiles produced by the trapezoidal roof tile machine not only have rich colors and diverse shapes, which can be integrated with various architectural styles to create a warm and comfortable living and working environment, but also have excellent weather resistance, which can withstand long-term wind and sun, rain and snow erosion, ensuring the long-term stability and safety of the roof.

3.Tourist attractions and ancient building restoration:

In the restoration of gardens, antique buildings and ancient buildings in tourist attractions, trapezoidal roof tiles also play an important role. By choosing the right raw materials and molds, the equipment can produce glazed tiles, antique tiles, etc. with traditional styles, and its realistic appearance and exquisite craftsmanship can perfectly restore the charm of ancient buildings and add historical and cultural atmosphere to tourist attractions. At the same time, these new roofing tile materials have advantages over traditional materials in terms of performance, which can better protect ancient buildings and extend their service life.

High-quality service guarantee:

Buying a trapezoidal roof tile machine is not only to buy a piece of equipment, but also to get a full range of service support. Zhongtuo has a professional pre-sales team, which can provide customers with personalized equipment selection plans and technical consulting services according to customer needs and actual production conditions. During the equipment installation and commissioning stage, we will send experienced technicians to the site to guide and ensure that the equipment can be put into use smoothly. In addition, we also provide perfect after-sales service, regularly return to customers, solve the problems encountered by customers in the process of use in a timely manner, and provide customers with one-stop services such as equipment repair, maintenance, and accessories replacement, so that customers have no worries.

With its efficient production capacity, excellent performance, wide range of applications and high-quality service guarantee, trapezoidal roofing tile machine has become the best choice in the field of roofing engineering. If you are looking for a reliable roofing tile processing equipment, you may wish to choose our trapezoidal roofing tile machine to create a better future together!