Work flow of the roll forming machine

https://www.youtube.com/watch?v=jG-d6ySUK9k

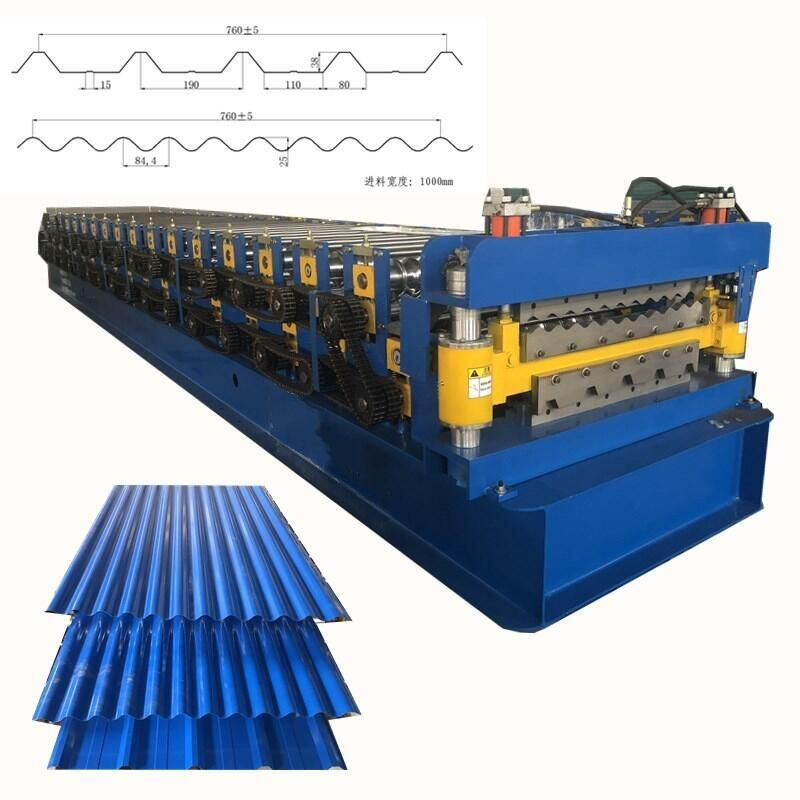

Introduction of double layer roll forming machine:

To meet the demand for forming two cross-sectional products within a limited space and facilitate quick product changeover, the double layer roll forming machine (also known as double layer color steel tile forming machine or double layer integrated equipment) has emerged as an innovative solution in the industry for multi-variety and small-space production scenarios.

Its ingenious design lies in the layered arrangement of high and low frames to achieve compatibility with two panel types: the roll set for producing one profile is fixed on the low frame, dedicated to processing panel types such as lapped tiles for bungalows; the roll set for the other cross-section (e.g., roof panels) is installed on the high frame.

The two sets of rolls operate independently while sharing the basic configurations of a production line, including an uncoiler and a cutting press. When raw materials are fed into the lower rolls, the first panel type can be quickly formed; if switched to feeding into the upper rolls, the machine can immediately produce the other cross-sectional product without occupying additional equipment or space.

To adapt to the double layer production mode of two panel types, key components of the equipment have been designed in a coordinated manner: the cutting die adopts a two-layer height structure to ensure that panels of different heights can be accurately cut, avoiding cutting errors caused by height differences;

the finished product handling equipment (such as conveying and stacking devices) behind the cutting die is equipped with flexible up and down adjustment functions, which can be real-time adapted to the exit heights of the two panel types, ensuring smooth connection of the whole process from forming to collection of finished products and reducing material jamming or damage caused by mismatched heights.

The advantages of this double layer integrated equipment are particularly prominent:

– Maximized space utilization: It enables the production of two panel types in the same space without the need to configure separate production lines for each product, significantly saving factory floor space. It is especially suitable for small and medium-sized processing plants with limited space or multi-variety and small-batch production scenarios.

– Significantly improved changeover efficiency: Product changeover can be completed through quick switching between high and low frames, eliminating the cumbersome process of replacing roll sets (such as disassembly, installation, and debugging) in traditional single-type machines.

The changeover time is shortened to minutes, effectively reducing production downtime and improving the effective operating rate of the equipment.

– Steady improvement in overall productivity: Due to convenient changeover and compact space, the equipment can flexibly switch between two panel types, adapting to rapid changes in orders, avoiding idle capacity during single panel type production, thus producing more diversified products per unit time and increasing the overall output rate.

– Better cost control: Sharing core equipment such as uncoilers and cutting presses reduces equipment procurement and maintenance costs; at the same time, reduced space occupation lowers operating costs such as rent, water, and electricity, balancing production flexibility and economy.

However, due to the compact structure, the equipment also has certain limitations: the dense layout of high and low frames restricts the installation space for auxiliary roll frames, which may affect the auxiliary support for the panel forming process; operators have relatively crowded operating space when adjusting roll parameters or checking forming details, increasing the difficulty of precise debugging.

But overall, its significant advantages in space saving, efficiency improvement, and cost control make it an ideal choice for balancing flexibility and economy in modern color steel tile production, especially suitable for enterprises that need to quickly respond to market demands and produce multiple varieties alternately.

The main parameters of the double layer machine

|

1.Formed Material

|

PPGI,PPGL

|

Material Thickness:24/26 Gauge (0.3-0.6 mm) Width:43inch(1092mm)

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

26 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

350mm H Beam Structure, With 18mm Welded Steel Middle Support Plate.

|

|||

|

Drive

|

gear and Double Chain transmission

|

|||

|

Dimension(L*W*H)

|

1.3m*1.65m*1.5m

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

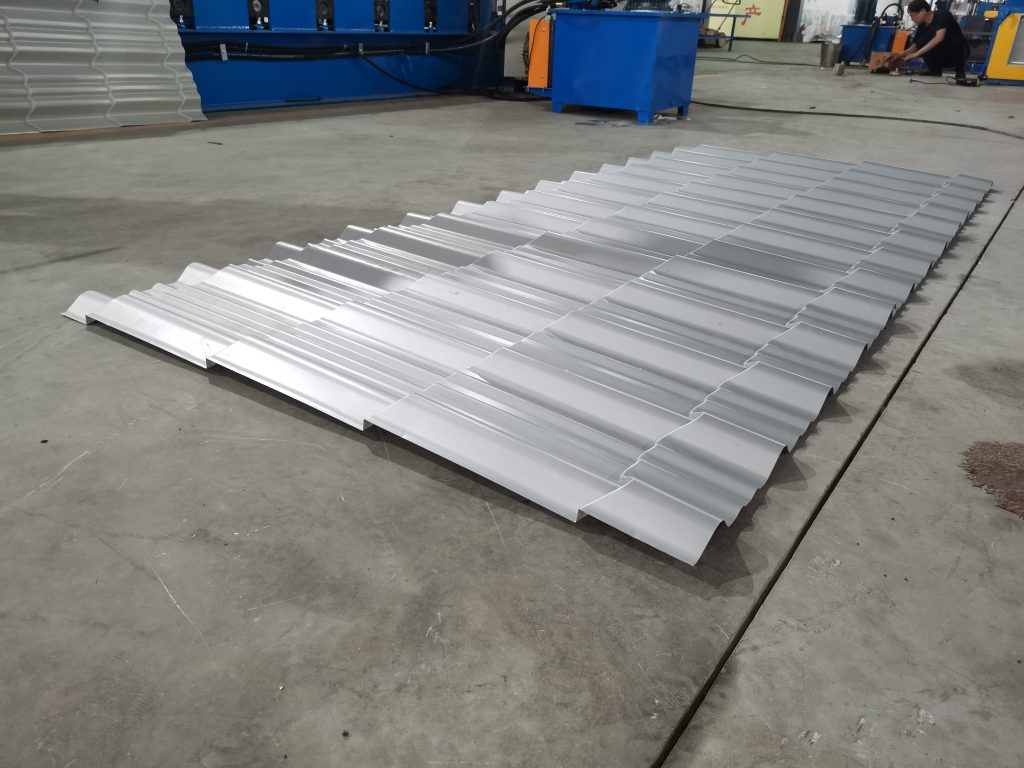

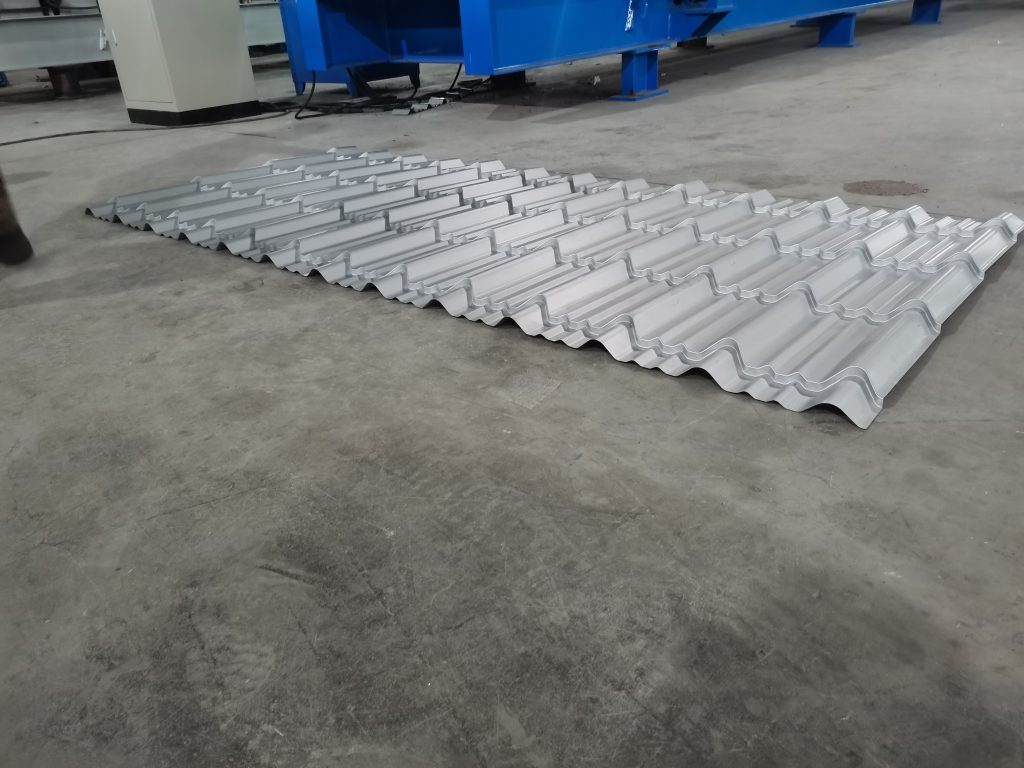

Finished product display about double layer roll forming machine

Related machine recommendations