Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.3-0.8mm Width:1000mm/1250mm(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

will give you as free

|

||

|

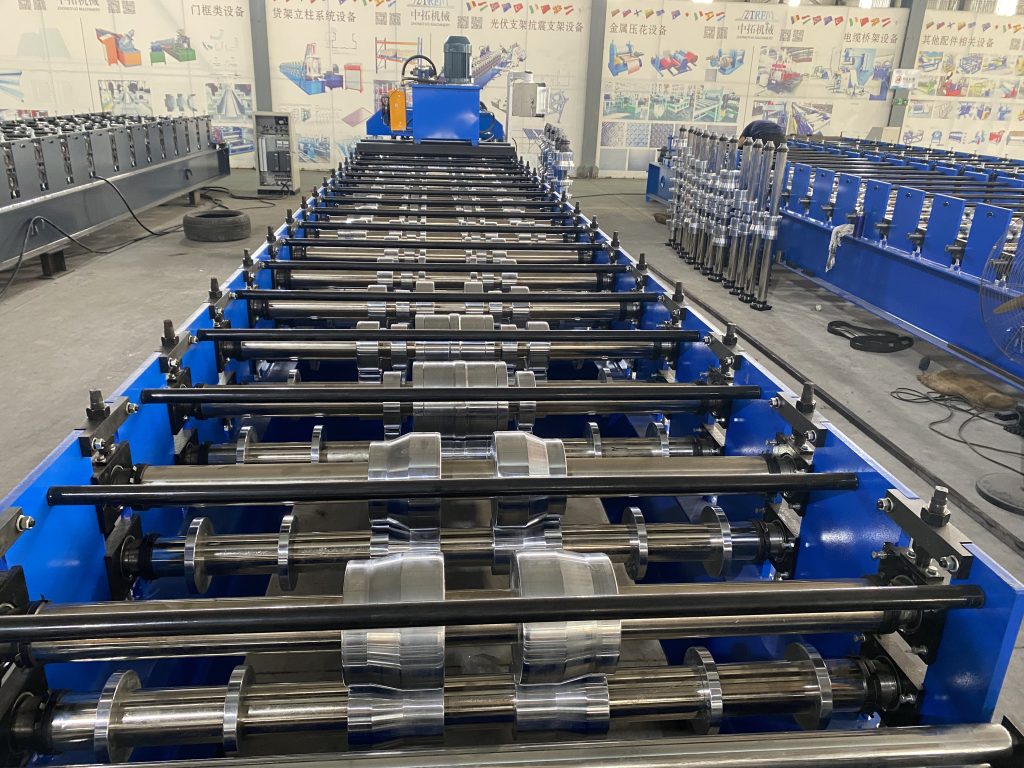

3.Main body

|

Roller station

|

18 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

as your requirement

|

|||

|

Dimension(L*W*H)

|

9500*1600*1600(customize)

|

|||

|

Weight

|

10T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

6.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

7.Forming Speed

|

15-25m/min

|

The speed is adjustable

|

||

Product Introduction:

In the construction industry, the selection of roofing materials and the performance of production equipment play a crucial role in the quality, aesthetics, and durability of buildings. Trapezoidal roof tiles are widely used in various buildings due to their unique shape design, excellent performance in drainage, windproof and structural stability. As the core equipment for the production of trapezoidal roof tiles, the performance of the trapezoidal roof tile machine directly affects the quality and production efficiency of the tiles. Trapezoidal roof tile machines mainly produce tiles through the process of cold forming or molding. Taking common cold-forming as an example, first place the coiled metal sheet (such as galvanized steel plate, color-coated steel plate, etc.) on the unloader, and the unloader smoothly unfolds the plate and feeds it into the guide device to ensure that the plate can accurately enter the subsequent process. The sheets then enter a forming system consisting of multiple forming rollers. These forming rollers bend the sheet step by step according to a pre-designed trapezoidal profile. In this process, the sheet is accurately bent into a trapezoidal section by precisely adjusting the spacing, angle, and travel speed of the forming roller. When the tiles are initially formed, enter the cutting device. The cutting device uses a high-speed cutter to cut off continuous tiles according to a set length to obtain trapezoidal roof tiles of the required specifications. The entire production process is usually monitored and adjusted by advanced control systems, and operators only need to input relevant parameters on the console, such as tile size, production speed, etc., and the equipment can automatically and efficiently complete production tasks.

Machine Features:

1.Efficient production:

The trapezoidal roofing tile machine adopts an automated production process, which can achieve continuous operation, fast production speed, and high production capacity. Compared with traditional manual or semi-automated production methods, its production efficiency can be greatly increased by several times or even dozens of times. Taking some advanced production lines as an example, the production speed can reach tens of meters per minute, and the output of a single production line in one day can meet the needs of large-scale construction projects, greatly shortening the construction period and improving the project schedule.

2.High-precision products:

With the help of precise forming molds and advanced control systems, the tiles produced by the trapezoidal roof tile machine have extremely high dimensional accuracy and good shape accuracy. The size deviation of the tiles can be strictly controlled within a very small range, for example, the length deviation can be controlled within ±1mm, and the deviation of wave height and wave distance can also be accurate to ±0.5mm. This high-precision product can achieve seamless splicing during the installation process, which not only improves the overall aesthetics of the roof, but more importantly, enhances the waterproof and windproof performance of the roof, ensuring the stability and safety of the building structure.

3.Strong material adaptability:

The machine is capable of processing many types of metal sheets, such as galvanized steel strips, cold-rolled steel strips, color-coated steel strips, etc., while also adapting to different thicknesses of plates, from thinner 0.3mm plates to thicker 1.0mm plates, capable of high-quality forming processing. Whether it is common metal materials for construction or some plates with special performance requirements, trapezoidal roof tile machines can achieve ideal molding results by adjusting equipment parameters and molding processes according to the characteristics of the material, meeting the diverse needs of different customers and construction projects.

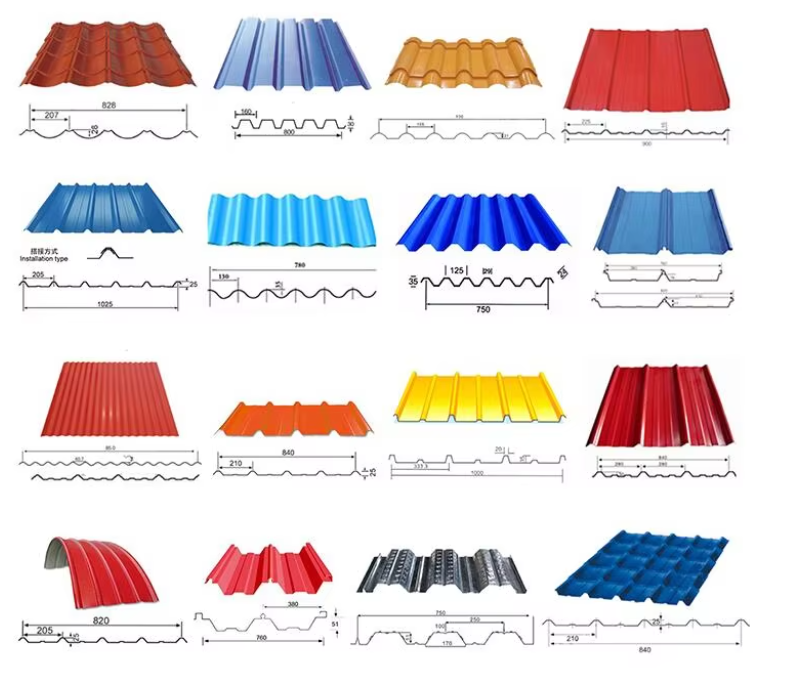

4.Versatility:

In addition to producing standard specifications of trapezoidal roof tiles, trapezoidal roof tile machines can also produce other shapes and specifications of roofing tiles, such as trapezoidal tiles with different wave heights and wave pitches, as well as some specially designed special-shaped tiles. In addition, some advanced equipment also has additional functions such as punching and embossing, which can punch holes of various shapes on the surface of tiles, or press unique patterns, meet the special requirements for the aesthetics and functionality of roof tiles in architectural design, realize multi-purpose in one machine, and improve the use value and return on investment of equipment.

5.Energy saving and environmental protection:

In the production process, the trapezoidal roofing tile machine adopts cold forming or molding process, which does not require heat treatment of the metal sheet, which greatly reduces energy consumption compared to the hot processing process. Moreover, due to the high production efficiency of the equipment, the energy consumption per unit product is correspondingly reduced, which is in line with the development trend of modern industrial energy conservation and environmental protection. At the same time, in the design and manufacturing process of the equipment, attention is paid to reducing noise and dust generation, creating a relatively comfortable and environmentally friendly working environment for operators.

Application Scenarios:

1.Industrial plants:

In the construction of industrial plants, trapezoidal roofing tiles have become the first choice for roofing materials due to their good waterproof and drainage properties and high strength. The tiles produced by the trapezoidal roofing tile machine can adapt to the roofing needs of large spans and large areas of industrial plants, and their sturdy and durable characteristics can withstand harsh industrial environments, such as strong winds, heavy rain, snow, etc., providing reliable protection for equipment and production activities in the plant. At the same time, the surface coating of tiles can also choose materials with anti-corrosion and anti-rust functions as needed, extending the service life of the roof and reducing maintenance costs.

2.Warehouse:

The requirements for the roof of the warehouse are mainly waterproof, moisture-proof and structurally stable to protect the stored goods from the external environment. The tiles produced by the trapezoidal roof tile machine have a tight lap structure and good waterproof performance, which can effectively prevent rainwater leakage. Moreover, its strong load-bearing capacity can cope with the pressure of cargo stacking or snow weight that the warehouse roof may bear. In addition, the installation of trapezoidal roofing tiles is simple and fast, and the laying of warehouse roofs can be completed in a short time, reducing the impact of construction on warehouse operations.

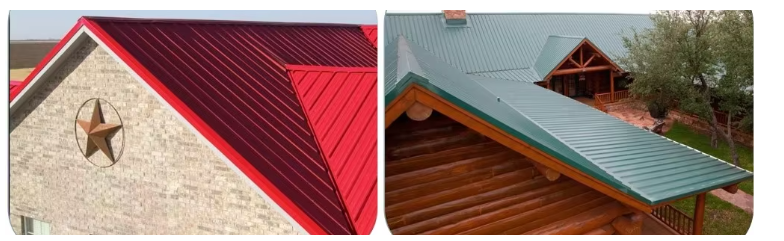

3.Residential Buildings:

In the field of civil housing, trapezoidal roof tiles not only have practical functions, but also enhance the aesthetics of houses. Its variety of colors and styles can match different styles of architecture, adding a unique charm to the home. At the same time, the sound insulation and heat insulation performance of trapezoidal roof tiles can also provide residents with a more comfortable living environment. In some earthquake-prone areas, lightweight and high-strength trapezoidal roof tiles can also reduce the overall weight of the house, improve the seismic performance of the house, and ensure the safety of residents’ lives and property.

4.Agricultural facilities:

such as agricultural greenhouses, breeding houses and other agricultural facilities, the requirements for roofing materials are economical and practical, corrosion resistance, and aging resistance. The cost of tiles produced by trapezoidal roof tile machines is relatively low, and they have good corrosion resistance and can adapt to acid-alkali erosion in agricultural environments. Its large drainage slope design can quickly drain rainwater and snow, avoiding damage to agricultural facilities. In addition, trapezoidal roof tiles are easy to install, allowing for quick construction of agricultural facilities to meet the timeliness needs of agricultural production.

5.Public buildings:

In public buildings such as gymnasiums, exhibition halls, and railway stations, trapezoidal roof tiles are also widely used. These buildings usually have large spaces and unique modeling designs, and the tiles produced by trapezoidal roof tile machines can be customized into different shapes and specifications according to the requirements of architectural design to achieve diverse roof shapes. At the same time, its high strength and stability can meet the strict requirements of public buildings for roof structure safety, providing security for the activities of a large number of people. Moreover, the fire resistance of the tiles also meets the fire safety standards of public buildings.

Products Display: