Cut to Length and Slitting line

https://www.youtube.com/watch?v=nEGFfgLkWEI

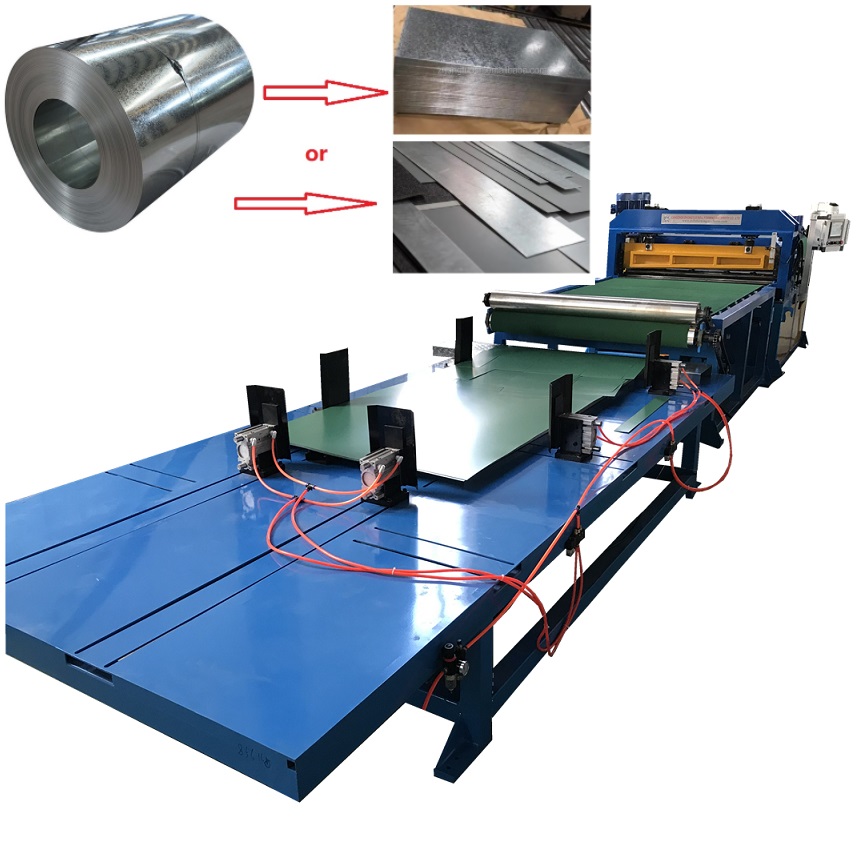

Introduction of the Automatic Line for the Cut to Length and Slitting of Steel Coils

The All-in-One Automatic Line for the Cut to Length and Slitting of Steel Coils is a state-of-the-art industrial apparatus meticulously engineered to streamline the processing of steel coils with unparalleled efficiency. By seamlessly integrating the two pivotal functions of cut-to-length and slitting, this advanced production line represents a significant leap forward in steel processing technology. Below is an in-depth exploration of its core elements:

Key Functions

1. Slitting: The slitting function of this integrated line is a sophisticated process that transforms a broad steel coil into multiple narrow strips, or slits, by executing precise longitudinal cuts. Leveraging high-precision cutting mechanisms, it enables the production of strips with exact widths tailored to diverse industrial applications.

For instance, in the electrical industry, it can produce thin strips for transformer laminations, while in the packaging sector, it can create strips of appropriate widths for manufacturing metal containers. This flexibility makes it an indispensable asset across various manufacturing fields.

2. Cut-to-Length: Complementing the slitting process, the cut-to-length function trims the slit strips, or the original coil when slitting isn’t required, into steel sheets of precisely defined lengths. Employing advanced measurement and control systems, it ensures that each cut adheres to strict dimensional tolerances.

This precision is crucial in industries like automotive manufacturing, where components need to fit together seamlessly, and construction, where standardized steel sheets are essential for structural integrity.

Advantages of the

– Efficiency: One of the most significant advantages of this all-in-one line is its remarkable efficiency. By combining the cut-to-length and slitting processes into a single production line, it eliminates the need for multiple setups and intermediate handling.

This precision not only meets but often exceeds the stringent quality standards of modern industries, enabling the production of high – quality steel products that can be used in critical applications.

– Versatility: With its adaptable design, the All-in-One Automatic Line can handle a diverse range of steel types, including cold-rolled, hot-rolled, galvanized, and stainless steel. It can also accommodate various thicknesses, from thin gauge sheets to thick plates.

This versatility allows manufacturers to use a single production line for multiple product lines, reducing capital investment and production complexity. Whether it’s for small – batch custom orders or large – scale mass production, this line can be easily reconfigured to meet different production needs.

The All-in-One Automatic Line for the Cut to Length and Slitting of Steel Coils has become an essential piece of equipment in modern industrial manufacturing. Its widespread adoption in industries such as automotive, construction, manufacturing, electrical, and packaging is a clear indication of its value.

As these industries continue to evolve and demand higher – quality, more precisely engineered steel products, the importance of this advanced production line is only set to increase.

Recommended related machine