Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.4-0.7mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

11 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Specifications

|

Customized

|

|||

|

Weight

|

About 3T

|

|||

|

4.Cutter

|

Automatic

|

Cr12 material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

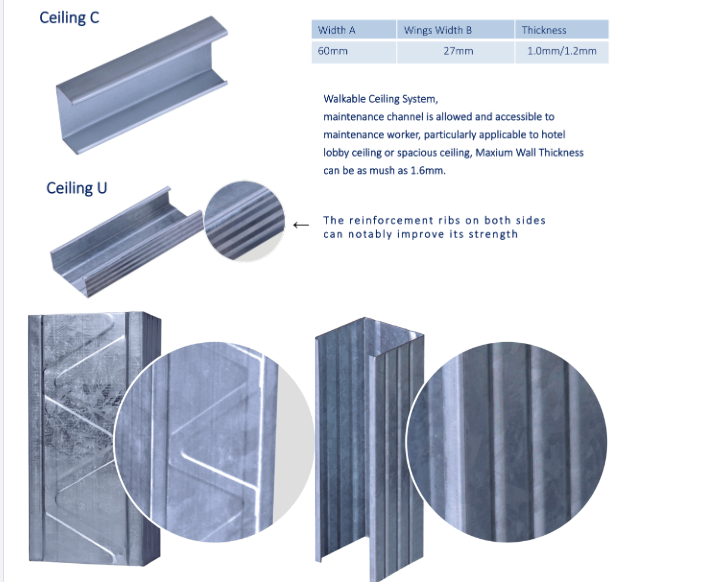

Product Description:

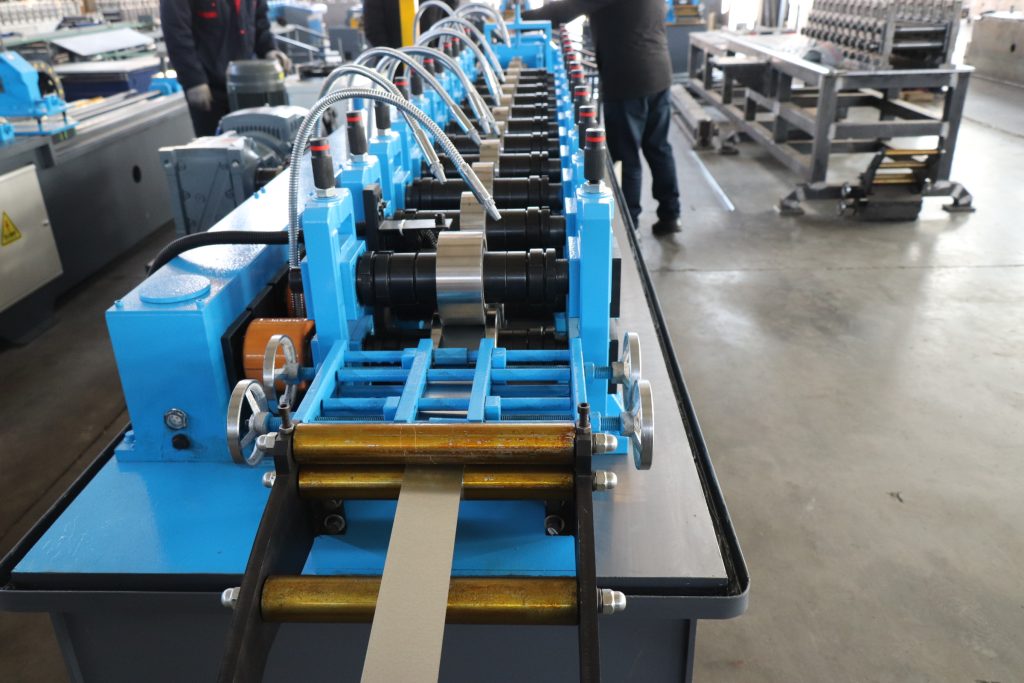

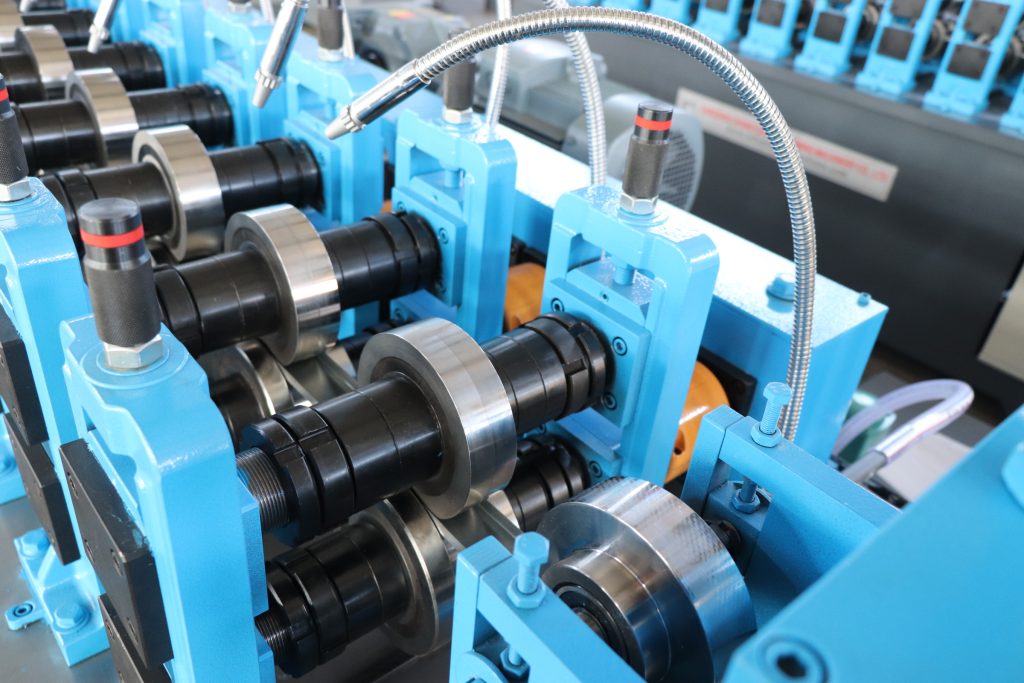

The drywall metal stud u channel steel roll forming machine is a specialized equipment used for producing U channel keels. It processes steel strips into U channel cross-sectional profiles through cold bending forming technology, mainly used for the skeleton structure of building partition systems and ceiling keel frames. The drywall metal stud u channel steel roll forming machine adopts cold rolling forming technology, which processes the strip steel into U channel section keel profiles through continuous cold rolling. Place the strip steel coil on the feeding rack and guide it to the forming area through guide rollers and positioning rollers. The strip steel gradually bends under the action of a series of forming rollers, ultimately forming a U channel cross-section. The formed keel is subjected to fixed length cutting using a hydraulic cutting device. The cut keel is output through a conveyor belt to complete production.

Main features:

1.Efficient production:

The production speed of the drywall metal stud u channel steel roll forming machine can reach 30-120 meters per minute, which can meet the needs of large-scale production.

2.Fully automated operation:

The equipment integrates functions such as automatic feeding, forming, cutting, etc., reducing manual intervention and lowering labor costs.

3.High precision molding:

Using high-precision molds and control systems to ensure accurate keel size, smooth surface, and stable quality.

4.Stable and reliable:

The equipment has a sturdy structure, operates smoothly, has a low failure rate, and ensures continuous production.

5.Flexible adaptation:

The specifications of the keel can be adjusted according to customer needs, suitable for various building scenarios.

6.Environmental protection and energy conservation:

adopting energy-saving design to reduce energy consumption in the production process.

Application areas:

- Construction engineering:

used for the manufacturing of light steel keel for walls, ceilings, partitions, etc. - Decoration and Renovation:

Suitable for the installation of indoor and outdoor decorative materials. - Industrial plant:

Used for the production of light steel keel for buildings such as factories and warehouses.

Products Display: