Here is the working video of this machine for everyone to watch:

Product Attributes :

|

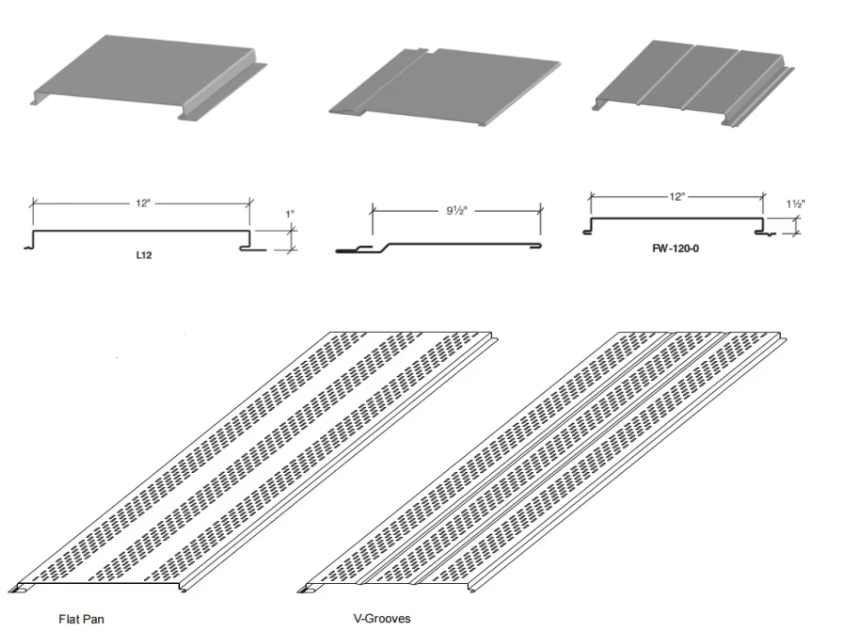

Profile

|

Customized and one machine adjustable for different profile

|

|||

|

Roller station

|

18 roller station

|

|||

|

Punching device

|

the punching roller are adjustable according to your needs,Punch or No punch

|

|||

|

Control system

|

PLC control System,Brand Simens

|

|||

|

Frame Construction

|

molding frame or pillar frame

|

|||

|

Support Material

|

PPGI,AI or others

|

|||

|

Forming Stations

|

All Rollers painted surface of the conductor pipe are hard chrome plated to insure long roll life and protect the finish.

|

|||

|

Driving part

|

All the stations of the machines are driving stations by gear, top and bottom. They are all spring loaded which creates a constant load on the material. The springs make our machines the most versatile on the market allowing you to run different material with virtually no adjustments. And also the machine can produce the profile with punching or without.

|

|||

Product Description:

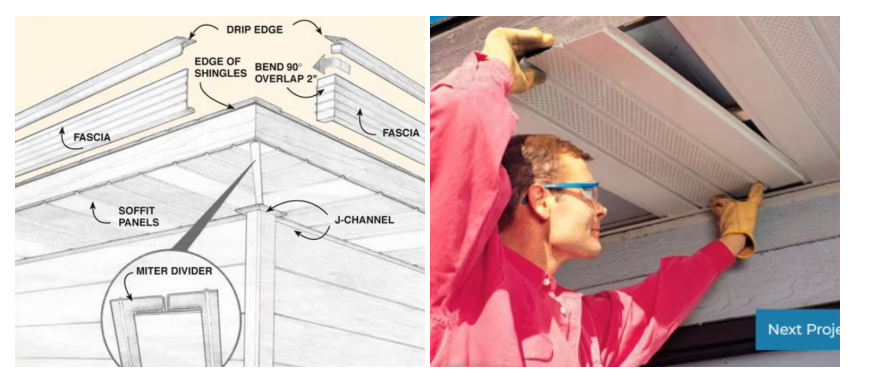

The ceiling soffit panel roll forming machine is mainly used for the decoration and functional implementation of building exterior walls, with both aesthetics and practicality. By fixing the board to the surface of the wall through dry hanging and other methods, personalized artistic design can be achieved to meet the aesthetic needs of commercial buildings, residential buildings, etc. For example, GRC hanging panels can be flexibly shaped, while metal exterior wall hanging panels can achieve details such as corners and door frames through hardware pendants. When the machine is made of materials such as double-layer special board, it has the characteristics of corrosion resistance, high temperature resistance, fire resistance, etc., which can effectively protect the building structure from environmental erosion. The metal hanging board also has sound insulation and noise reduction functions, improving indoor comfort. The machine adopts mechanized equipment (such as exterior wall hanging board machine) to achieve quick installation without seasonal restrictions, and hidden installation can reduce damage to the building structure. For example, cabinet installation solutions can conceal equipment and reduce visual interference. Some materials, such as composite metal plates, have thermal insulation functions to reduce energy consumption; Although single-layer metal plates have weaker insulation effects, they are more cost-effective and suitable for simple structural buildings.

Main features:

1.High degree of automation:

The equipment adopts advanced PLC control system, which can achieve automatic batching, forming and cutting, reducing manual intervention.

2.High production efficiency:

Capable of quickly producing a large number of hanging boards with consistent specifications to meet the needs of large-scale construction projects.

3.Stable product quality:

By precise process control, ensure the strength, flatness, and dimensional accuracy of the hanging board.

4.Environmental protection and energy conservation:

There is no discharge of three wastes during the production process, which meets the requirements of green environmental protection.

5.Wide applicability:

The produced hanging boards can be used for various scenarios such as indoor and outdoor ceilings, exterior wall decoration, etc.

Application scope:

- Indoor ceiling:

Ceiling decoration in places such as offices, schools, hospitals, shopping malls, etc. - Exterior wall decoration:

used for decorating and insulating the exterior walls of buildings, enhancing their appearance and performance. - Acoustic treatment:

In places with high acoustic requirements such as concert halls, theaters, and conference rooms, hanging boards can provide good sound absorption effects.Finished product image:

Products Display: