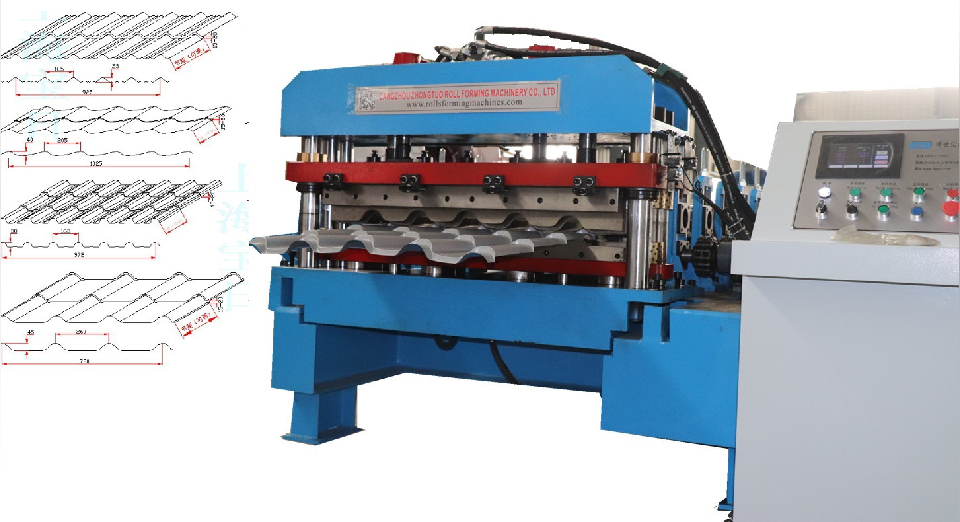

Work flow of Glazed Tile Sheet Roll Forming Machine

https://www.youtube.com/watch?v=i94pUN77v9k

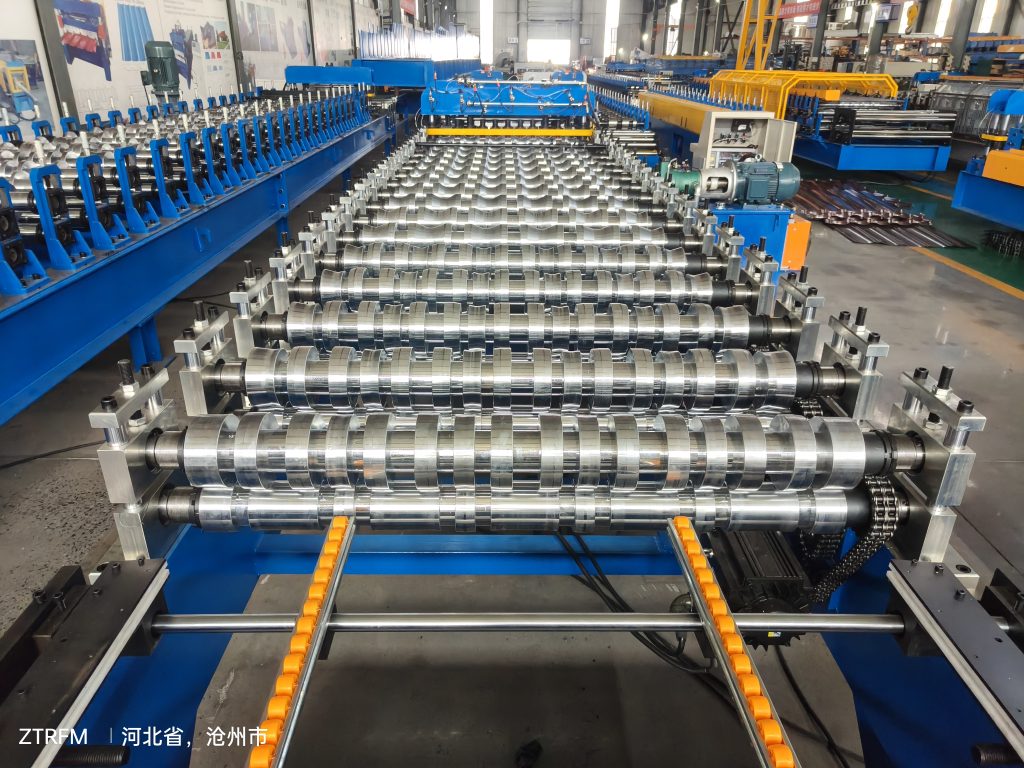

Specification of Glazed Tile Sheet Roll Forming Machine

| PPGI,GI,AI | Thickness:0.3-0.8mm | ||

| Hydraulic automatic decoiler | Manual decoiler(will give you as free) | ||

| Roller station | As your requirement | ||

| Diameter of shaft | 80mm solid shaft | ||

| Material of rollers | 45# steel, hard chrome plated on the surface | ||

| Machine body frame | 350 H steel | ||

| Drive | gearbox transmission(as your requirement) | ||

| Dimension(L*W*H) | 9500*1600*1600(customize) | ||

| Weight | 10T | ||

| Automatic | cr12mov material, no scratches, no deformation | ||

| Motor Power | 7.5KW | ||

| Hydraulic system power | 5.5KW | ||

| 380V 50Hz 3Phase | As your requirement | ||

| Electric Box | Customized(famous brand) | ||

| Language | English(Support multiple languages) | ||

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | ||

| 0-15/min | The speed depends on the shape of the tile and the thickness of the material. |

Features and Benefits About the Glazed Tile Sheet Roll Forming Machine

As a new type of roofing building material production equipment, the antique colored steel glazed tile forming machine adopts advanced roll forming technology and intelligent control system, which can efficiently convert 0.3-0.6mm thick color coated steel plates (PPGI/PPGL) into high-precision antique glazed tiles. The equipment can accurately reproduce the soft curves and three-dimensional stepped shapes of traditional glazed tiles through a precisely designed multi-pass roll forming mold system. The formed tiles not only retain the aesthetic characteristics of the eaves and corners of ancient buildings, but also achieve the industry-leading level of ±1.5mm in dimensional accuracy control.

The PLC intelligent control system integrated in the equipment is equipped with an HMI human-machine interaction interface, which supports one-click setting and automatic calibration of production parameters, and can realize the full process automation from coil unwinding, roll forming, cut-to-length to finished product collection. The core forming roller group adopts Cr12MoV alloy steel substrate and is chrome-plated on the surface. With the mirror polishing process, the surface hardness reaches HV850 or above, which effectively avoids scratches on the material surface and mold wear, ensuring continuous production of 200,000 linear meters without quality attenuation.

The colored steel glazed tiles produced by this equipment have both structural strength and decorative performance. According to SGS testing and certification, the coating has a salt spray resistance of more than 1,000 hours, and its weather resistance meets the requirements of GB/T 1771 standard. It still maintains good mechanical properties and color stability in extreme environments of -40°C to 80°C. The product density is only 1/30 of that of traditional clay tiles, and the single sheet bearing capacity is 800N, which effectively reduces the load on the building roof. It has the characteristics of light weight, high strength, fire retardant (B1 grade), and self-cleaning. It is widely used in antique building repair, cultural tourism project construction and modern commercial building roof decoration projects.

Recommended related machine

Application of glazed tiles