Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,PPGL,AI,Etc.

|

Material Thickness:0.3-1.0mm

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

Due to your requirement profile

|

||

|

Diameter of shaft

|

Due to your requirement profile

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

Due to your requirement profile

|

|||

|

Drive

|

gear and Double Chain transmission/gearbox transmission optional

|

|||

|

Dimension(L*W*H)

|

Due to design

|

|||

|

Weight

|

Due to design

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW(normally)

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

As your requirement

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

0-15m/min

|

Provide customized

|

||

Product Description:

Standing seam metal roof sheet roll forming machine: a perfect integration of traditional craftsmanship and modern technology

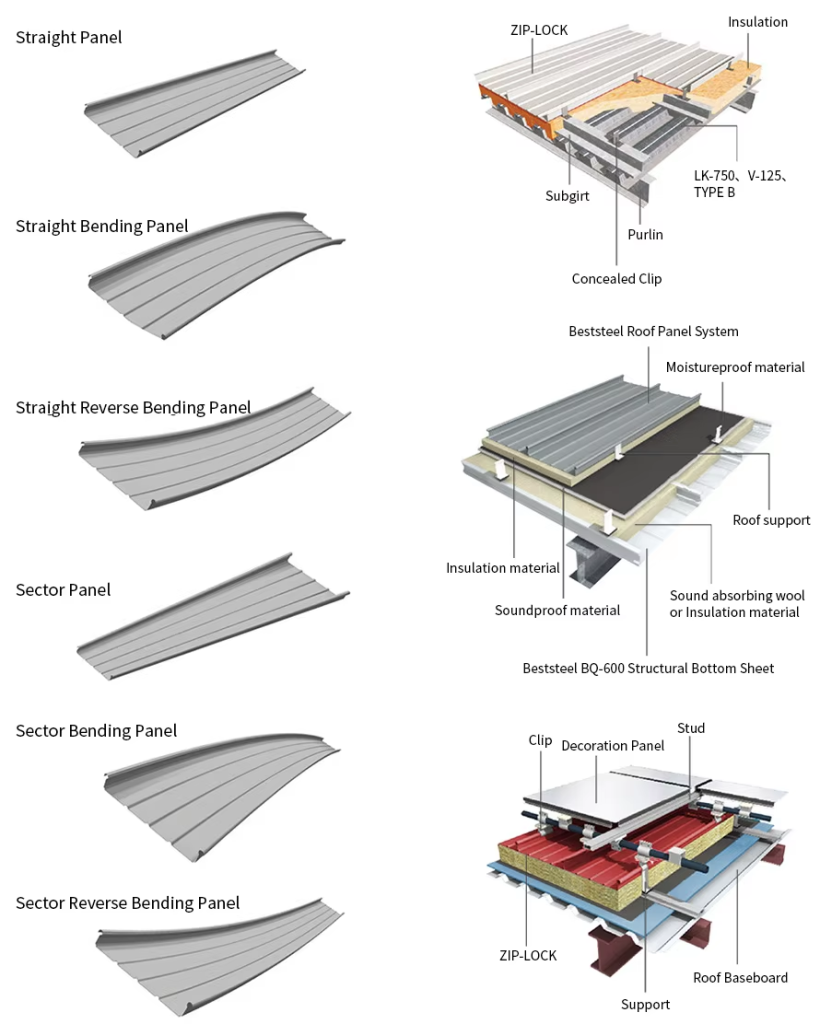

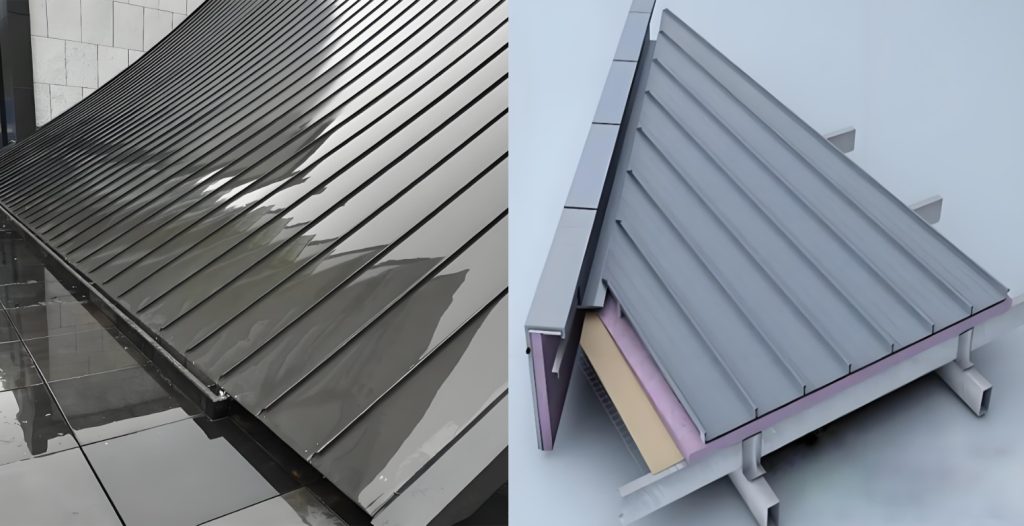

As the “fifth facade” of a building, the waterproofing and aesthetics of the roof are crucial. As the core equipment for metal roof processing, the vertical seam roof tile machine is reshaping the modern architectural skyline with efficient and precise processing technology. This article will systematically introduce its technological advantages, and industry applications.

Technical advantages:

- Efficient construction:

The standing seam metal roof sheet roll forming machine can quickly achieve tile splicing and self-locking, greatly improving construction efficiency and reducing installation time and labor costs. The self-locking (fast locking) standing seam design enables tiles to be quickly assembled and locked during installation, reducing the installation time of a single tile from the traditional 3 minutes to 40 seconds. - Excellent waterproof performance:

The standing seam roof tiles produced by the standing seam metal roof sheet roll forming machine can effectively enhance the waterproof performance of the roof and prevent rainwater leakage through a unique splicing method. This design is particularly suitable for roofs with small slopes and can meet high waterproof requirements. - Strong adaptability:

The portable machine designed for the standing seam metal roof sheet roll forming machine can adapt to complex construction environments, especially in residential areas. Its single-phase voltage requirements make it easier for the machine to work in household electrical environments. This design simplifies the complexity of construction operations and improves the convenience of construction. - Structural stability:

Mechanical locking joints are connected between tiles through mechanical connectors, which are more secure and can withstand greater external forces such as strong winds and snow. They are suitable for building projects that require high stability of roof structures.

Application scenarios:

1.Buildings with smaller roof slopes:

When the roof slope is small, the flow rate of rainwater on the roof is relatively slow, and higher waterproof performance requirements are placed on the roof. The unique splicing method of the vertical seam roof tiles produced by the standing seam metal roof sheet roll forming machine can effectively enhance the waterproof performance of the roof and prevent rainwater leakage.2.Buildings that require high waterproof performance:

Standing seam roof tiles, through their unique splicing method, can significantly improve the waterproof performance of the roof, making them suitable for building projects that require high waterproof performance.3.Portable construction requirements:

In residential areas, portable standing seam metal roof sheet roll forming machines can be transported more conveniently, and can even be directly lifted to the roof for operation, greatly simplifying the complexity of construction operations.

Products Display: