Here is the working video of this machine for everyone to watch:

Product Attributes :

1. Roller specifications: DIA450~500mm, width: 1000~2000mm.

2. Take the roll surface hard chromium plating

3. Suitable for pressing plate: 1-6 mm

4.Frame steel plate welded structure, polished, tempering, machining, solid wall plate Q235 90 mm thick

5. Pattern processed by laser engraving.

6. The pattern making: according to the buyer to provide the sample pattern

7. Pressure mode: hydraulic 50~100T.

8. Working speed: 0-10m/min, speed changed by frequency converter .

9. Voltage 380V/50Hz/3PH or customize

10. Safety shield shell

11. Beautiful appearance

Product Description:

Metal embossing machine is a device used for embossing on metal surfaces, widely used for surface treatment of various metal materials such as aluminum plates, color steel, copper plates, stainless steel plates, etc. Its main function is to imprint metal surfaces through embossing rollers, forming various patterns or textures to meet different decorative or functional needs. Metal embossing machines usually adopt a suction plate structure, which transfers the heat of the heating plate to the fusion surface of the upper and lower plastic heating elements through electric heating method, causing the surface to melt. Then, the heating plate is quickly withdrawn, and the fusion surface of the upper and lower heating elements is fused, solidified, and integrated after heating. The whole machine is in the form of a frame, consisting of three large plates: an upper template, a lower template, and a hot template. It is equipped with a hot mold and upper and lower plastic cold molds, and the action mode is pneumatic control.

Application areas:

Metal embossing machines are widely used for surface treatment of various metal sheets, including aluminum plates, color steel plates, copper plates, stainless steel plates, etc. It has a wide range of applications, such as:

1.Architectural exterior wall decoration:

used to make metal exterior wall decorative panels, providing a beautiful appearance and protective effect.

2.Home appliance manufacturing:

applied to the outer shell of household appliances such as refrigerators and cold storage to improve the appearance quality of products.

3.Vehicle manufacturing:

Applied in the fields of car flooring, door manufacturing, etc., to enhance the aesthetics and durability of products.

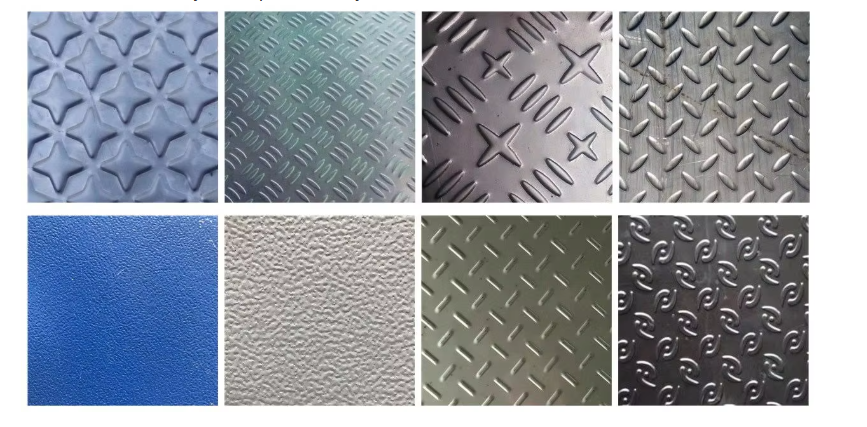

There are also many other pattern for your reference:

Products Display: