How to make Snap Lock Standing Seam Metal Sheets?

Below is a workflow video for you to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,PPGL,AI,Etc.

|

Material Thickness:0.4-0.8mm

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

Due to your requirement profile

|

||

|

Diameter of shaft

|

Due to your requirement profile

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

Due to your requirement profile

|

|||

|

Drive

|

gear and Double Chain transmission/gearbox transmission optional

|

|||

|

Dimension(L*W*H)

|

Due to design

|

|||

|

Weight

|

Due to design

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW(normally)

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

As your requirement

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

0-80m/min

|

Provide customized

|

||

The advantage of this Snap Lock Standing Seam Metal Sheet Roll Forming Machine:

- Efficient production:

The snap lock standing seam metal sheet roll forming machine adopts advanced CNC technology and automatic feeding system, which can quickly and accurately cut and process metal sheets, greatly improving production efficiency. - Precision machining:

The equipment is equipped with high-precision CNC machine tools and advanced machining processes to ensure accurate size and shape of the product, and reliable quality. - Multifunctionality:

It can produce roof tiles of different specifications and shapes to meet diverse market demands. - Environmental protection and energy conservation:

Adopting energy-saving technologies and environmentally friendly materials to reduce energy consumption and emissions in the production process, in compliance with environmental protection requirements.

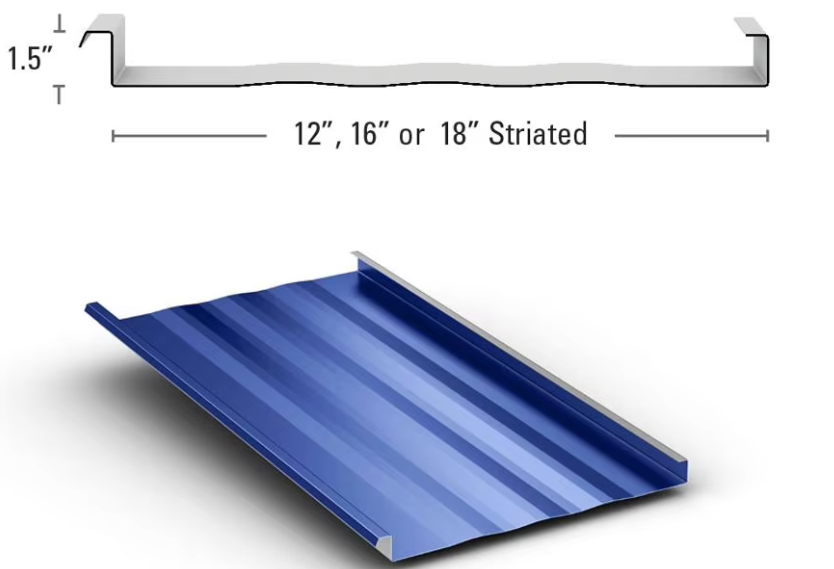

Product Description:

The snap lock standing seam metal sheet roll forming machine is a specialized equipment for producing snap lock standing seam metal sheets, mainly used for processing metal sheets and manufacturing roof tile materials that meet the requirements through cutting, bending, welding and other processes. This type of equipment usually has the characteristics of high efficiency, precision, and versatility, and can meet the production needs of roof tiles of different specifications and shapes. Widely used in the construction industry, especially in projects that require high-quality roofing materials. The roof tiles produced by it have excellent properties such as waterproofing, wind resistance, and thermal insulation, and are suitable for laying roofs on various buildings.

Products Display: