Metal roll forming standing seam machine is a specialized equipment for producing standing seam roof panels, mainly used in the construction industry, especially in the installation of roof and wall systems. The standing seam roof panel machine produced by Zhongtuo is widely used in the installation of roof and wall systems in the construction industry. Its 360 degree upright mechanical lock seam design ensures that there are no nails on the entire roof, eliminating the risk of water leakage and ensuring good drainage and sealing performance. In addition, our equipment can also be customized with colors according to customer needs, providing a variety of choices.

Features and functions:

1. High production efficiency:

The Metal roll forming standing seam machine adopts advanced CNC technology, which can quickly and accurately cut and process materials, greatly improving production efficiency. The equipment is equipped with an automatic feeding system and an intelligent control system, which can automatically adjust the cutting speed and processing accuracy to ensure efficient and stable production process.

2. Reliable quality:

Using high-precision CNC machine tools and advanced processing techniques to ensure the accuracy and quality of products. The equipment is also equipped with an advanced quality inspection system to conduct strict quality testing on products, ensuring that every product meets the standard requirements.

3. Wide applicability:

Suitable for processing aluminum manganese magnesium alloy sheets of various specifications, it can produce roof panels of different specifications and shapes. The equipment can also be customized according to customer needs to meet the needs of different customers.

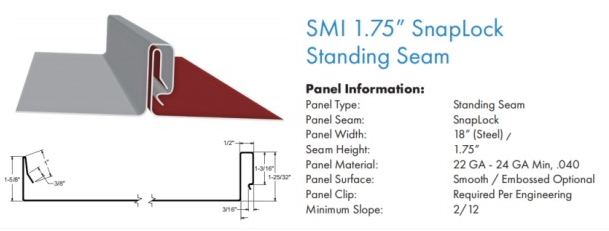

Pattern diagram:

Product main components:

| No. | Name | Unit | Quantity |

| 1 | 3T decoiler | set | 1 |

| 2 | Feeding,pinch, and pre-cutter part | set | 1 |

| 5 | Roll forming part | set | 1 |

| 6 | Product run-out table | set | 1 |

| 7 | PLC control station | set | 1 |

| 8 | Hydraulic oil pump station | set | 1 |

| 9 | Spare parts | set | 1 |

Product Attributes :

| No | Components | Item | Parameter |

|

1 |

Decoiler/uncoiler |

3ton manual decoiler |

Capacity: 3ton

Coil inner dia:450-550mm Feeding width: max 500mm |

| 2 | Feeding, pinch and pre-cutter | Pinch rollers | 2sets |

| Shearing type | hydraulic pre shearing | ||

| Blade material | Gcr12 quenched treatment | ||

|

3. |

Main roll forming part |

Machine frame | 350mm H beam structure,

Outside steel wall plate is connected by screw on the frame surface being sandblasted |

| Forming stations | 20 rollers stations | ||

| Material of rollers | high grade No.45 forged steel, with digital-controlled procession, surface hard chromium plating to ensure long lifetime | ||

| Diameter of shafts | Φ70mm full axis | ||

| Material of shafts | High grade 45#, all shafts are tooled by grinding machine for two times to ensure the precision of final product. | ||

| Forming speed | 0-20m/min | ||

| voltage | 380V,60HZ,3 Phrase or as your request | ||

| Transmission way | By chain | ||

| Main motor | 5.5KW Siemens brand | ||

| 5. | PLC control station | PLC brand | PLC, Siemens brand of buttom and low-voltage apparatus

Friendly man-machine interface system can be set batches to the workpiece, length, quantity, etc. |

| language | English and Chinese | ||

| encoder | Omron brand | ||

|

6 |

Hydraulic oil pump station |

Hydraulic station motor | 3KW |

| type | With air-cooling system | ||

| Main components | Include a set of hydraulic tank, a set of hydraulic oil pump, four hydraulic pipes. And two sets of electromagnetism valves | ||

| 7 | Product run-out table | type | 3m Simple table |

| 8 | Spare parts | tooling | One set |

| others | Chain, gear, fuse, travel switch, encoder |

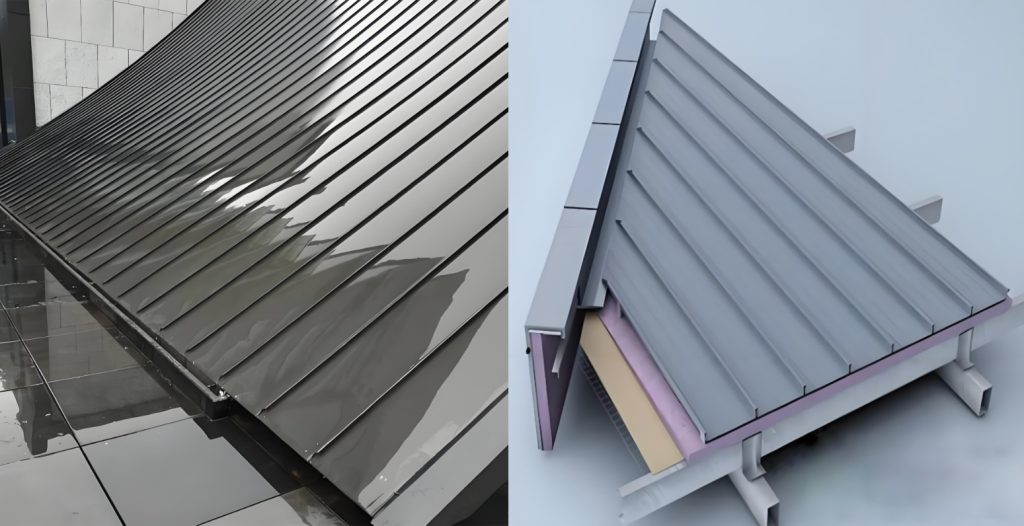

Products Display: