The CZ purlin automatic changeable cold roll forming machine adopts infinite transformation technology, which can be adjusted in millimeters within the specification range. It is not only suitable for the production of standard plate shapes, but also for the production of non-standard plate shapes. Its infinite changeover and infinite cutting functions enable cutting after forming without the need for tool change, making changeover quick and greatly improving production efficiency and flexibility. The equipment mainly consists of a passive loading rack, a leveling device, a punching device, a cutting device after forming, a hydraulic station, and a computer control system. It uses an automatic flying saw for punching and is easy to operate.

Technical features:

- Infinite transformation system:

TheCZ purlin automatic changeable cold roll forming machine adopts infinite transformation technology, which can be adjusted in millimeters within the specifications. It can not only produce standard plate shapes, but also non-standard plate shapes. The perfect combination of infinite transformation and infinite cutting has created the first high-speed infinite roll forming equipment in history that does not require blade replacement and can quickly transform after forming. - Efficient production:

CZ purlin automatic changeable cold roll forming machine has the characteristics of efficient production, which can quickly manufacture various components required for construction and transportation, meeting the needs of large-scale production and rapid delivery. - Precise control:

By precisely controlling the molding process, components that meet various process requirements can be produced to ensure product quality and stability.

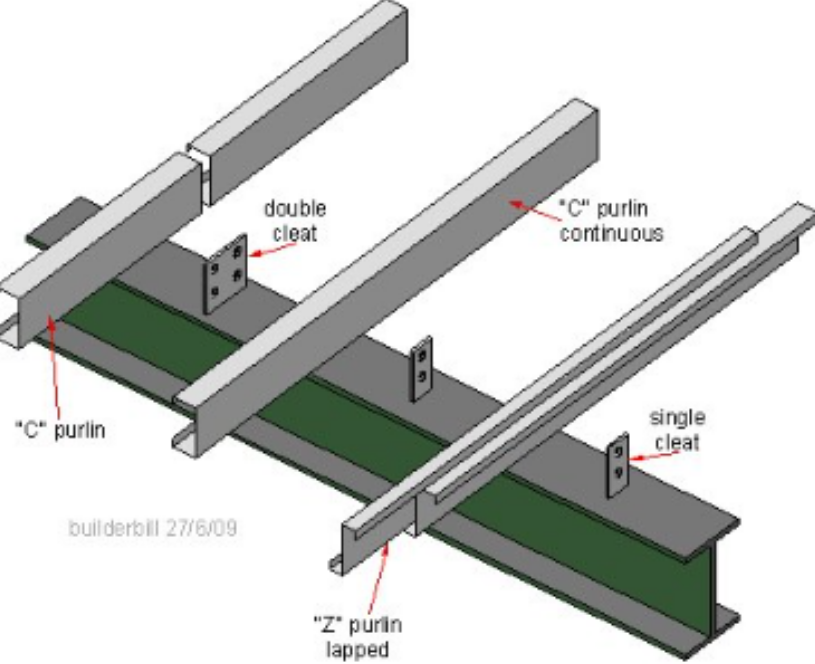

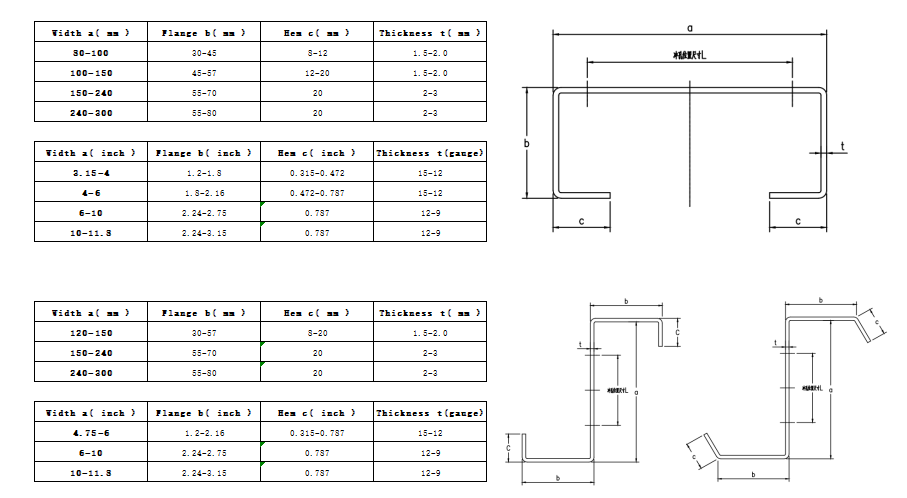

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

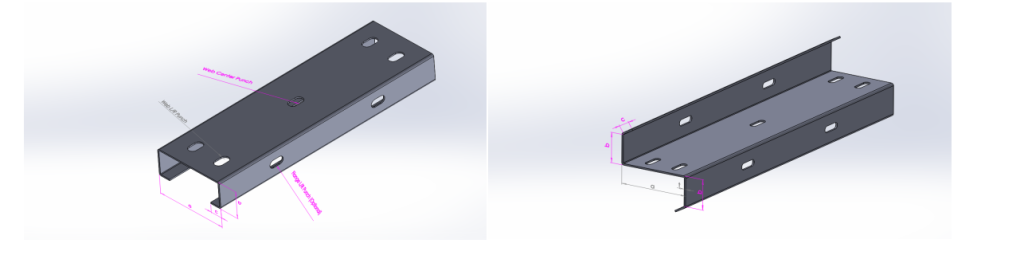

Products Display:

Product Work Video: