0.3-1mm thickness Floor Deck Roll Forming Machine for Roofing and Wall Sheet Fully Automatic

Product Attributes :

|

Size of main part

|

about 15000 х 1850 х 1500 mm(as your requirement)

|

|||

|

Weight of main part

|

about 6t

|

|||

|

Processing material

|

235 Mpa

|

|||

|

Material thickness

|

0.3-1mm

|

|||

|

Input material width

|

1220mm

|

|||

|

Voltage

|

380 v 50 hz 3 phase or as request

|

|||

|

Frame

|

400 H beam steel welded

|

|||

|

Roller fixer

|

Middle plate (thickness 20mm)

|

|||

|

Drive mode

|

as your requirement

|

|||

|

Material of rollers

|

Gcr15 quenching treat HRC58-60

|

|||

|

Material of shafts

|

45# steel precision-machined

|

|||

|

Diameter of shafts

|

φ 95 mm

|

|||

|

Number of rollers

|

as your requirement

|

|||

|

Drive motor power

|

Hydraulic unit motor power 7.5kW

|

|||

|

Forming speed

|

0-15 m per minute

|

|||

The advantage of Floor Deck Roll Forming Machine:

- Efficiency and precision:

The Zhongtuo floor deck roll forming machine adopts advanced automated production technology, which can directly position and fix prefabricated floor slabs in predetermined positions without the need for on-site concrete pouring, greatly shortening the construction period and reducing labor costs. In addition, the automation of equipment operation makes the production process more precise and stable, effectively reducing errors caused by manual operation. - Customization and Intelligence:

Zhongtuo’s floor deck roll forming machine supports customized production and can adjust parameters such as thickness, wave height, and length of the slab according to customer needs. In addition, the device has a high degree of intelligence, and parameter settings and monitoring can be completed through the human-machine interface, making it easy to operate.

Product Description:

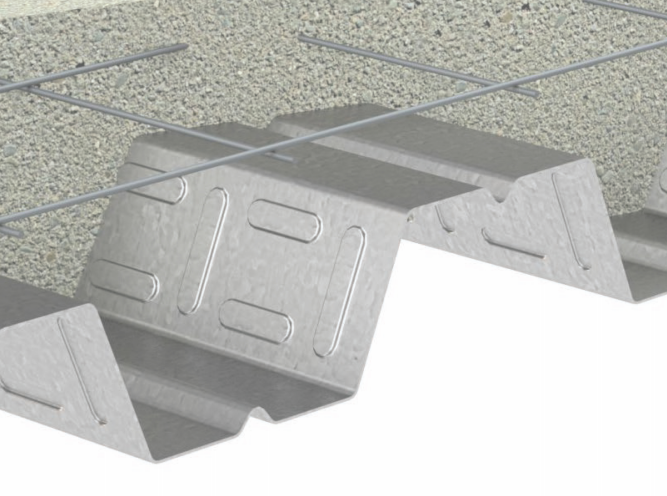

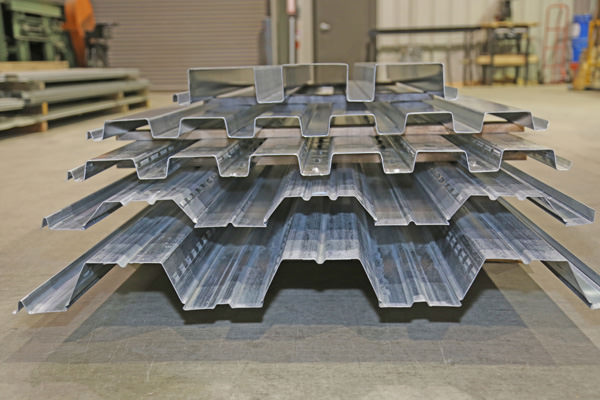

The floor slab machine is an automated production equipment designed specifically for the construction industry, mainly used for producing non pouring floor slabs. This type of equipment significantly improves the production efficiency and quality of floor slabs by optimizing the process flow, while reducing labor costs and material waste. The core function of the floor slab machine is to achieve automated forming of floor slabs, using advanced mechanical structures and control systems to accurately complete processes such as sheet pressing, cutting, and forming.

The floor slab has high strength and good bearing capacity, which can withstand large loads and spans, and is suitable for complex building structures such as large-span and high-rise buildings. Floor slabs can effectively absorb and disperse seismic forces, reducing the damage to buildings caused by earthquakes. For example, steel truss floor slabs are suitable for buildings with high seismic requirements due to their excellent load-bearing capacity and stiffness.Products Display: