https://www.youtube.com/watch?v=ua4dP9uYqio

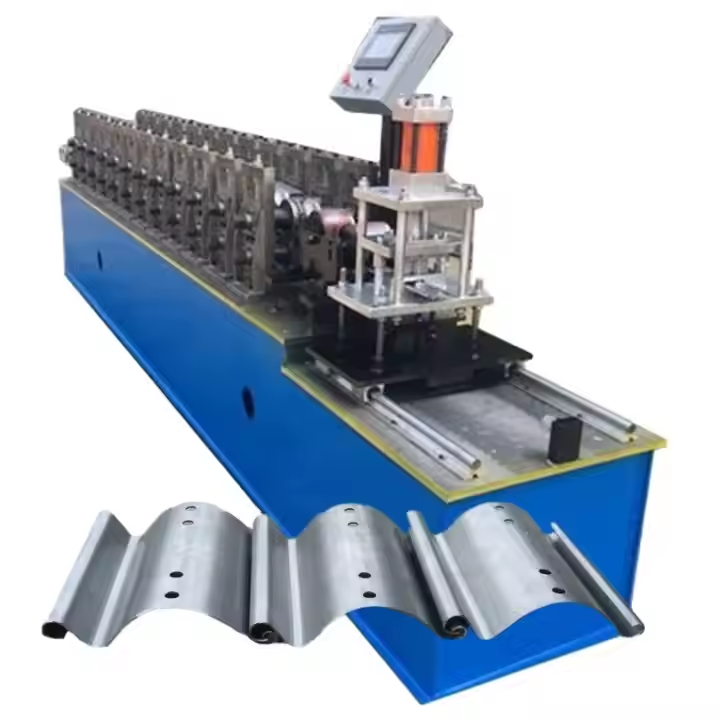

Automatic Door Frame Forming Equipment: High Accuracy & Low Maintenance

The door frame forming equipment is an automated production line specially designed for metal sheet forming. It offers a wide range of raw material options, including galvanized steel sheets, color-coated steel sheets of various colors, and aluminum sheets. The finished products processed by this equipment find extensive applications in the construction field: they can serve as external roof panels and wall cladding for buildings, protecting the structure from wind, rain, and temperature fluctuations; they can also function as interior decorative wall panels or ceiling panels, adding aesthetic appeal and a sense of hierarchy to the space.

Features of the Forming Moulds for Door Frame Forming Equipment

– The moulds have a high degree of customization and can be tailor-made according to the specific specifications and shape requirements of customers. All forming moulds are made of high-quality Gcr15 steel, and the materials undergo strict forging treatment before processing to improve the material’s density and mechanical properties, laying a foundation for the durability of the moulds.

– It has established a good reputation in the production of stainless steel forming moulds and always adheres to the bottom line of quality, never cutting corners. During the mould processing, each procedure follows strict technical standards, and the dimensional control is carried out by precision measuring tools throughout the process. For example, key parameters such as length and outer diameter can be strictly controlled within an error of 0.1mm under the precise measurement of vernier calipers, and the runout error can even be controlled within 0.05mm, ensuring that the precision of the moulds meets the high standards of the industry.

– The mould products themselves have excellent characteristics such as high strength and high wear resistance. At the same time, according to customer requirements, additional surface heat treatment processes such as carburizing and nitriding can be carried out. These processes can significantly improve the service life of the rolls, and the hardness of the treated moulds can reach HRC56-60, which is sufficient to cope with long-term high-intensity production operations. This feature makes the moulds almost maintenance-free after being put into the machine, greatly reducing the trouble of production interruption caused by equipment failure for users and lowering the repair cost.

– The forming effect of the moulds is excellent: the formed arc parts are round and full without wrinkles or deformation; the flat parts are smooth and flat without bulges or depressions; the angle parts are sharp and clear without fillets or deviations. After polishing, the surface of the mould has a high gloss, and it will not scratch or wear the surface of the material during contact with the raw materials, ensuring the appearance quality of the finished products.

– The forming design of the moulds follows the physical properties and deformation laws of the materials, and the forming process is natural and reasonable, which can effectively avoid problems such as cracking and wrinkling of the materials due to excessive stress. All forming moulds are strictly debugged and inspected by technical personnel before leaving the factory to ensure that their parameters meet the production requirements and can operate stably after being put into the machine.

Forming Process of Door Frame Forming Machine

The adopts a fully automated production process, with the specific steps as follows:

– Automatic feeding: The raw material coil is automatically unfolded through the feeding device to ensure the continuity and stability of material transportation.

– Guiding: The material enters the guiding device, and the positioning structure ensures that it maintains the correct traveling direction in the subsequent processing to avoid deviation.

– Leveling and feeding: The material is leveled by the leveling mechanism to eliminate the bending stress of the coil itself, making the material surface flat; at the same time, the feeding device conveys the material to the next process at a set speed.

– Continuous punching: According to the product design requirements, the punching mechanism performs continuous and precise punching on the material to form the required hole structure.

– Forming: The material enters the forming unit and is gradually bent and deformed under the continuous action of multiple sets of moulds, finally forming the door frame section shape that meets the design requirements.

– Sizing and cutting: When the formed material reaches the set length, the cutting device starts to cut the material accurately to ensure the consistency of product length.

– Receiving: The cut finished products are collected and sorted by the receiving device for subsequent storage and transportation.

Technical Conditions of Door Frame Forming Equipment

– Equipment floor area: The overall dimensions are 30 meters in length × 3.0 meters in width × 2 meters in height. Corresponding installation space needs to be reserved in the workshop to ensure that there is sufficient operating and maintenance area around the equipment.

– Equipment feeding direction: The left-in and right-out layout design is adopted, which is convenient for operators to plan and arrange the production line according to the workshop layout.

– Voltage parameters: The applicable power supply is 380V, 50Hz three-phase alternating current, and a stable power supply system must be equipped to ensure the normal operation of the equipment.

– Air source requirements: A compressed air source is required, with a flow rate of 0.5m³/min and a stable pressure of 0.6MPa, to provide sufficient power for the pneumatic components of the equipment.

– Hydraulic oil specification: The hydraulic system needs to use 46# hydraulic oil, which has appropriate viscosity and good wear resistance, ensuring the efficient operation of the hydraulic system.

– Gear oil specification: The gear transmission part of the equipment needs to be filled with 18# hyperbolic gear oil to reduce friction and wear between gears and prolong the service life of transmission components.

Product Features of Door Frame Forming Equipment

– This Door Frame Forming Equipment machine is designed and manufactured by a team with rich experience, integrating advanced design concepts and mature processing technology to ensure that the equipment reaches the industry-leading level in terms of structural rationality and operational stability.

– The processing of key components is completed by CNC equipment. Through high-precision automated processing, the dimensional accuracy of core parts such as rollers is guaranteed, providing a foundation for the stable operation of the equipment.

– Thanks to high-precision processing technology and accurate assembly and debugging, the overall operation of the equipment is stable, and it is not prone to failures during production, thus ensuring that the produced products have stable quality and uniform specifications, and reducing the rate of defective products.

– The cutting device of Door Frame Forming Equipment is driven by a hydraulic system. Compared with the traditional mechanical cutting method, it has lower noise, and the cutting process is stable, which can accurately control the product length with minimal error.

– The Door Frame Forming Equipment equipment adopts an overall automatic control system. Operators can complete parameter setting, production start, shutdown and other operations through the control panel, which is convenient and efficient, reduces manual intervention, and minimizes human operation errors.

Performance of Door Frame Forming Unit

– Applicable materials: It can process metal sheets such as galvanized sheets and low-carbon steel (such as common grades like Q235), meeting the material performance requirements of different construction scenarios.

– Range of sheet thickness: The equipment is suitable for processing sheets with a thickness of 0.8mm ≤ thickness ≤ 1.5mm, and sheets within this range can be stably formed on the equipment.

– Range of sheet width: It can handle sheets with a width of 150mm ≤ width ≤ 300mm, meeting the production needs of various specifications of door frame products.

Production floor area: The floor area of the entire production line is 30 meters in length × 3 meters in width, and the workshop layout must be planned according to this size.

– Total installed capacity: The total installed power of the equipment is 42kw, and the corresponding load capacity must be considered when planning the power supply system.

– Equipped air source requirements: A compressed air source with a flow rate of 0.9 cubic meters per minute and a pressure in the range of 0.6~0.7MPa is required to provide sufficient and stable power for the pneumatic components of the equipment.

Recommend related machine