Work Flow of The Omega Roll Forming Machine

https://www.youtube.com/watch?v=ecI-4BgObI8

Omega keel machine primarily uses strip steel as raw material and produces complex cross-section profiles through continuous cold rolling forming. Its product range is extensive, including light steel keels, painted keels, clip-in keels, various construction profiles, steel structures, steel-lined door frame profiles, and high-speed guardrails, as well as cold bending and painting unit equipment of different specifications. The entire production process is controlled by PLC, ensuring precise and efficient operation.

Advantages of Omega Keel Machine

– It adopts PLC control, which is equipped with multiple safety protection mechanisms during normal production to ensure operational safety.

– The machine bed is a steel plate welded part, and after tempering treatment,

it can eliminate internal stress and prevent the machine body from deforming during operation.

– The forming frame is of cast iron structure, which has undergone tempering treatment, resulting in high rigidity and a long service life.

– The material of the roll shaft is 40Cr, and after quenching and tempering treatment,

its hardness reaches HB280, ensuring stable performance during rolling.

– The forming die is made of GCr15, which is subjected to quenching treatment, with a hardness ranging from HRC56 to 62, ensuring excellent wear resistance and forming accuracy.

– The transmission structure is gearbox transmission.

Each forming frame is equipped with components related to the light steel keel machine, which can guarantee the equipment to run for a long time and with high intensity, and has a long service life.

Processing Technology of Omega Keel Machine

Uncoiling – Straightening – Roll Forming – Cutting – Coiling

Equipment Composition of Omega Keel Machine

It is composed of uncoiler, guide frame, forming host, correction device, fixed-length cutting part, coiling table, electrical control part, etc.

For the Omega Profiles Roll Forming Machine parameters for your reference:

| Voltage | 380V ,50Hz, 3Phase (as customer request) |

| Frame type | Memorial arch frame |

| Drive mode | Chain as transmission |

| Material of rollers | GCr12mov |

| Material of shafts | 45# steel with tempering |

| Diameter of shafts | Φ70mm |

| Number of rollers | 15 rollers with dotting rollers |

| Main power | 7.5 kw |

| Raw Materials of the steel coil | Galvanized steel plate |

| Material thickness | 0.5-1.2 mm |

| Forming speed | 20 m per minute |

Main Features of Omega Keel Machine

– The equipment is fully automatically controlled, with multiple safety protections set during normal production. It can realize unmanned control, saving human resources.

– The machine bed is a steel plate welded part, which is tempered to eliminate internal stress and avoid deformation of the machine body.

– The forming frame is of cast iron structure, which is tempered to have high rigidity and long service life.

– The forming die is made of die steel, which is quenched to a hardness of HRC56-62.

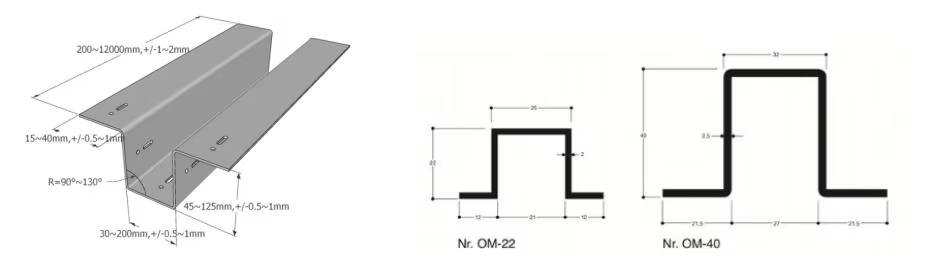

Common profile drawings

Recommend related machine