In the rapidly developing wave of the modern construction industry, the roof system, as an important component of the building, directly affects the progress of the entire construction project in terms of quality, efficiency, and cost control. Traditional trapezoidal roof panel production relies heavily on manual operations, which not only results in low production efficiency and poor product quality stability, but also fails to meet the standardization and high-precision requirements of large-scale construction projects for roof panels. In this context, the fully automatic trapezoidal roof panel machine has emerged, which has revolutionized the production mode of trapezoidal roof panels with its core advantages of intelligence and automation, and has become a key equipment for promoting the industrial upgrading of the construction industry. The emergence of fully automatic trapezoidal roof panel machines is not only a technological innovation in the field of construction equipment, but also an important force in promoting the industrialization and intelligent development of the construction industry. It solves the pain points in traditional roof panel production for construction enterprises with efficient production capacity, stable product quality, and significant cost advantages, helping enterprises enhance their market competitiveness. With the continuous upgrading of technology, fully automatic trapezoidal roof panel machines will play a greater role in the wave of green and intelligent construction, injecting new vitality into the high-quality development of the construction industry.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness(0.4-0.7mm) Width(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Ordinary decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

10-20 rows(As your requirement)

|

||

|

Diameter of shaft

|

70mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive chain

|

1.2inch(As your requirement)

|

|||

|

Dimension(L*W*H)

|

10000*1600*1600(customize)

|

|||

|

Weight

|

4-6T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

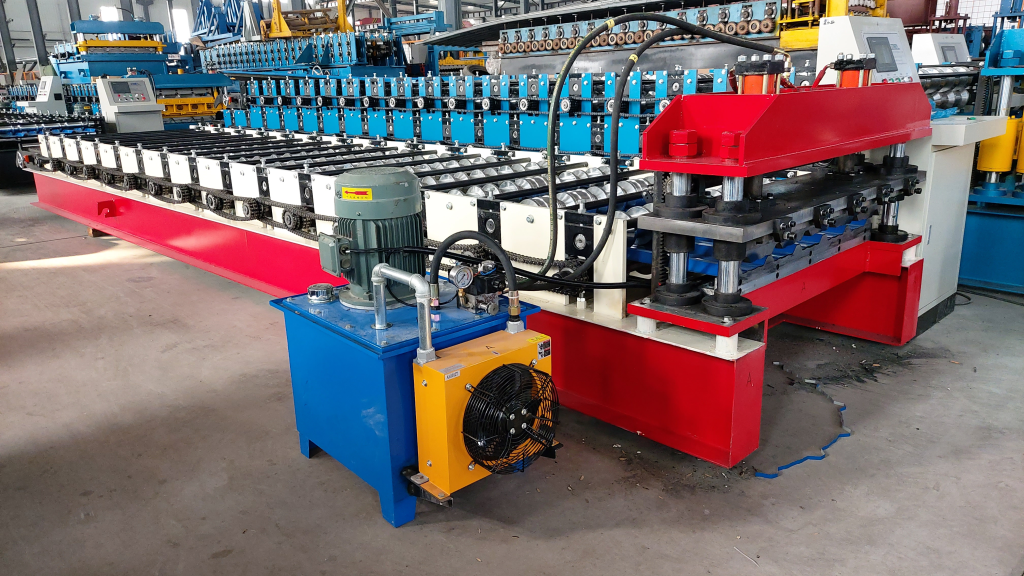

The core structure : precision components create efficient performance

The fully automatic trapezoidal roof panel machine is not a single device, but a complete production line composed of a series of precision components working together. Its core structure revolves around the production logic design of “automated feeding precise forming intelligent cutting efficient output”, mainly including the following key parts:

1.Material release mechanism:

As the starting point of production, the material release mechanism adopts a hydraulic tensioning device, which can adapt to metal coils of different widths and thicknesses (such as color steel plates, galvanized plates, etc.). This mechanism can automatically adjust the tension of the coil, avoiding problems such as deviation and wrinkles during the feeding process, ensuring the stability of raw material transportation, and laying the foundation for subsequent forming processes.

2.Leveling device:

Metal coils are prone to bending and deformation during storage and transportation. The leveling device uses multiple sets of precision rollers to continuously roll and correct the coils. The device is equipped with a built-in pressure sensor and intelligent control system, which can automatically adjust the roller pressure and speed according to the material and thickness of the coil. The flatness error of the coil is controlled within ± 0.5mm, ensuring the appearance and structural accuracy of the formed roof panel.

3.Molding host:

This is the “core heart” of the machine, using a multi pass progressive molding process. The host is equipped with 20-30 sets of customized forming rollers, each set of rollers corresponding to one forming step of the trapezoidal roof panel – from the initial flat plate pre bending, to the gradual shaping of trapezoidal peaks and valleys, and then to the precise pressing of edge locking, without manual intervention throughout the process. The forming roller is made of high-strength alloy steel material, and after quenching treatment, its hardness can reach HRC55 or above. It not only ensures the consistency of the forming dimensions of the roof panel (wave height and wave distance error ≤ 0.3mm), but also extends the service life of the equipment and reduces maintenance costs.

4.Cutting system:

Unlike traditional manual cutting or semi-automatic cutting, the fully automatic cutting system adopts hydraulic drive or servo motor drive, combined with high-precision laser positioning or encoder counting, to achieve fixed length cutting of roof panels. The operator only needs to input the required length (such as 3m, 6m, 12m, etc.) in the control system, and the system can automatically calculate the cutting position with a cutting error controlled within ± 1mm. At the same time, the cutting system is equipped with dust-proof and noise reduction devices, which can ensure the smoothness of the cutting surface and improve the production environment, meeting the requirements of environmentally friendly production.

5.Control system:

The “brain” of the entire machine adopts industrial grade PLC (programmable logic controller) combined with touch screen operation interface, with functions such as parameter setting, production monitoring, and fault alarm. Operators do not require professional programming knowledge and can adjust production parameters such as molding speed, cutting length, and coil tension through the touch screen; The system can also display production progress and equipment operating status in real time (such as current, temperature, pressure, etc.). When the equipment encounters abnormalities (such as coil breakage, roller jamming, etc.), it will immediately sound and light an alarm, and prompt the cause of the fault and troubleshooting methods on the screen, greatly reducing the operating threshold and fault handling time of the equipment.

The workflow : “one click” production from coil to finished product

The workflow of the fully automatic trapezoidal roof panel machine is highly automated, and the entire process does not require manual intervention, achieving a “one click” conversion from metal coil to finished trapezoidal roof panel. The specific steps are as follows:

1.Raw material preparation:

The operator lifts the metal coil onto the tensioning shaft of the feeding mechanism, fixes the coil with a hydraulic device, and then inputs information such as coil material (such as color steel, galvanized), thickness (usually 0.3-1.2mm), roof panel forming parameters (wave height, wave distance, plate width), and cutting length into the control system.

2.Automatic feeding and leveling:

After starting the equipment, the feeding mechanism transports the coil to the leveling device at a stable speed according to the control system instructions; The leveling device uses intelligent pressure regulation to continuously correct the coil, eliminate the bending stress of the coil, and ensure that the coil enters the forming host smoothly.

3.Multi pass progressive forming:

After the flat coil enters the forming host, it is gradually pressed by 20-30 forming rolls in sequence – first, the edge of the coil is pressed into a preliminary shape by pre bending rolls, then gradually shaped into trapezoidal peaks and valleys by intermediate rolls, and finally the size and shape of the roof panel are accurately calibrated by shaping rolls to ensure that the peak height and wave spacing width of each roof panel are completely consistent.

4.Fixed length cutting and output:

The formed continuous roof panels are transported to the cutting system, and the encoder records the real-time conveying length of the roof panels. When the set length is reached, the cutting system quickly starts and completes precise cutting within 1-2 seconds; The cut finished roof panels are automatically transported to the finished product stacking area through conveyor rollers. Some high-end models are also equipped with automatic stacking devices, which can neatly stack the finished roof panels according to the number of layers, facilitating subsequent handling and storage.

5.Production monitoring and data statistics:

Throughout the entire production process, the control system collects real-time production data (such as output, pass rate, equipment running time, etc.) and automatically generates production reports. Operators can export reports through USB flash drives for production management and cost accounting purposes; At the same time, the system will back up the operating data of the equipment to provide data support for subsequent equipment maintenance and production optimization.

Core advantage: A “three win” solution that reduces costs, increases efficiency, and improves quality

Compared with traditional manual or semi-automatic production methods, the fully automatic trapezoidal roof panel machine, with its intelligent and automated characteristics, has brought multiple advantages of “cost reduction, efficiency improvement, and quality improvement” to the construction industry, which are specifically reflected in the following aspects:

1.Significantly improve production efficiency and shorten project cycle:

Traditional manual production of trapezoidal roof panels requires 3-5 people to cooperate, with a daily output of only 500-800 square meters; The forming speed of the fully automatic trapezoidal roof panel machine can reach 10-20m/min, and the daily output can reach 2000-5000 square meters, increasing production efficiency by 3-5 times. For projects that require a large number of roof panels, such as large factories, logistics warehouses, and steel structure venues, the use of fully automated machines can significantly shorten the production cycle of roof panels and avoid project delays caused by insufficient supply of roof panels.

2.Ensuring stable product quality and reducing rework risks:

Manual production is affected by factors such as the technical level and fatigue level of operators, and roof panels are prone to problems such as uneven wave peaks, edge warping, and cutting length deviation. The product qualification rate is usually only 85% -90%; The fully automatic machine controls the molding error and cutting error at the millimeter level through precision mechanical structure and intelligent control system, and the product qualification rate can be increased to over 99%. Stable product quality not only reduces rework and repair costs caused by roof panel quality issues, but also improves the waterproof performance and structural stability of building roofs, extending the service life of buildings.

3.Reduce manual dependence and overall costs:

On the one hand, fully automated machines only require 1-2 people for equipment monitoring and raw material replenishment, which can reduce labor demand by more than 70% compared to traditional production methods, significantly reducing labor costs such as wages and social security; On the other hand, machine production can effectively reduce raw material waste (traditional manual production has a material utilization rate of about 90%, while fully automated machines can reach over 98%), while also reducing equipment damage and maintenance costs caused by manual operation errors. Taking the daily production of 3000 square meters of roof panels as an example, using fully automated machines can save comprehensive costs of 500000 to 1 million yuan per year.

4.Adapting to diverse demands and enhancing market competitiveness:

With the diversification of architectural design, the market’s demand for specifications (such as wave height, wave spacing, and plate width) and materials (such as color steel, aluminum magnesium manganese, galvanized sheet) of trapezoidal roof panels is becoming increasingly diverse. The fully automatic trapezoidal roof panel machine can quickly switch between producing roof panels of different specifications and materials by replacing the forming rollers (replacement time only takes 1-2 hours) and adjusting the control system parameters, without the need to rebuild the production line. This flexible production capacity can help companies quickly respond to customer needs, expand their business scope, and gain an advantage in fierce market competition.

Applicable scenarios:

The fully automatic trapezoidal roof panel machine, with its high efficiency, precision, and flexibility, is widely used in various construction projects, mainly including:

1.Industrial plants and logistics warehouses:

These types of buildings have a high demand for roof panels with uniform specifications, and fully automated machines can achieve large-scale production to meet the rapid construction needs of the project; At the same time, the machine produced roof panels have high precision, which can improve the sealing and waterproofing of the roof, ensuring the safety of equipment and goods in the factory.

2.Steel structure venues and public buildings:

such as sports halls, exhibition centers, airport terminals, etc., have complex roof designs and high requirements for the diversity of roof panel specifications and appearance quality. The fully automatic machine can produce roof panels with different wave heights and lengths, adapting to complex roof shapes while ensuring the flatness and aesthetics of the roof panels.

3.Residential and commercial buildings:

In modern steel structure residences, villas, and commercial complexes, trapezoidal roof panels are often used as the core components of roof enclosure systems. The roof panels produced by fully automated machines have stable quality and can improve the sound insulation and thermal insulation performance of residential buildings, meeting green building standards.