In today’s fast-paced construction industry, angle steel keels serve as core supporting components in curtain walls, steel structures, and interior decoration. Their processing efficiency and precision directly impact the progress and quality of engineering projects. Traditional manual processing or simple equipment operation is not only time-consuming and labor-intensive, with high error rates, but also fails to meet the demands of large-scale, standardized production. The emergence of Wall Angle Roll Forming Machine Iron Slotted Angle Beads Making Machines has completely addressed this industry pain point, revolutionizing processing methods for companies and becoming a key piece of equipment to boost competitiveness.

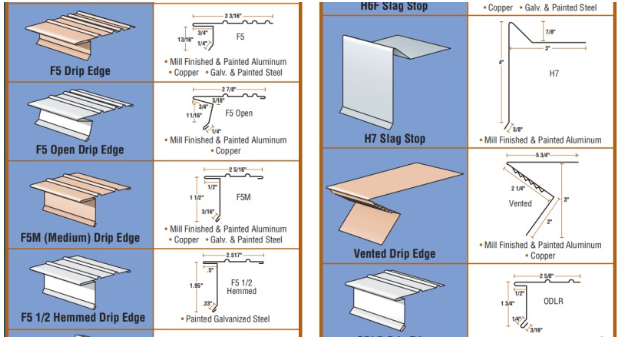

Pattern drawing:

Application areas:

1.Curtain Walls:

In the world of curtain walls, angle steel keel machines are skilled craftsmen, meticulously shaping support keels. With precise dimensional control and accurate punching, the keels seamlessly integrate with curtain wall panels and embedded components, creating a sturdy barrier that withstands wind, rain, and earthquakes, significantly enhancing the stability and safety of the overall structure.

2.Steel Structure Engineering:

Across the vast landscape of steel structure engineering, angle steel keel machines are tireless production giants, diligently crafting the purlins and support keels required for steel structures like factories and exhibition halls. Their robust mass production capacity acts as a continuous source of power, precisely meeting the stringent component quantity and quality requirements of large-scale projects, safeguarding project progress and ensuring the smooth completion of architectural visions.

3.Decoration and Renovation:

Entering the creative world of decoration and renovation, angle steel keel machines transform into dynamic artistic assistants. Using flexible and adjustable parameters, it tailors interior ceiling and partition trusses to the unique needs of various decorating styles. From minimalist and modern to classical and opulent, it easily adapts to a wide range of styles, eliminating tedious construction tasks and maximizing efficiency like a vibrant musical note.

4.Transportation Facilities:

In the construction of transportation facilities, the angle steel truss machine serves as a resilient and reliable guardian, specializing in the production of key components such as highway guardrail support trusses and subway platform decorative trusses. Its core components, with exceptional wear resistance, easily withstand the long-term processing challenges of high-strength angle steel. Like a steel guardian, it maintains its position, ensuring the superior quality of the trusses it produces, laying a solid foundation for the durability and reliability of transportation facilities.

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.2-0..4mm (customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

70m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Fully automated operation, eliminating inefficiencies and tedious processes

This angle steel keel machine is equipped with an advanced CNC system, fully automating the entire process, from raw material feeding, punching, cutting, to forming. Requiring no frequent manual intervention, simply enter preset parameters on the control panel, and the machine will accurately execute each processing instruction. For example, for processing common 50×50mm angle steel, traditional equipment can process less than 30 pieces per hour, while this machine can consistently process 80-120 pieces per hour, nearly tripling efficiency. Furthermore, automated operation significantly reduces labor costs, allowing a single worker to easily manage multiple machines, effectively alleviating labor pressure on businesses.

High-precision processing, ensuring project quality

For building components, precision is the foundation of safety and durability. This angle steel keel machine utilizes high-quality servo motors and precision guides, achieving a processing error of within ±0.1mm, far exceeding the industry standard of ±0.5mm. From punching position accuracy to cut surface smoothness, it perfectly meets the highest engineering standards. During curtain wall stud installation, precise machining dimensions reduce on-site adjustment time, ensure tight stud splicing, enhance overall structural stability, and avoid safety hazards caused by dimensional deviations. Furthermore, the machine’s intelligent detection system monitors the machining process in real time, instantly shutting down and issuing an alarm if any anomalies occur, further ensuring product quality.

Versatile Adaptability to Meet Diverse Needs

Considering the diverse stud specifications required for different projects, this angle steel stud machine offers robust compatibility and flexibility. It accommodates angle steel sizes ranging from 30×30mm to 100×100mm. By quickly changing dies, punching diameter, hole spacing, and cutting length can be flexibly adjusted without having to replace the entire machine, significantly reducing equipment investment costs. Whether custom stud processing for small decorative projects or mass production for large steel structure projects, this machine can easily handle both small and large-scale steel structure projects, providing strong support for business expansion.