In industries such as building materials, hardware manufacturing, and decoration engineering, the appearance, texture, and structural performance of metal materials directly determine the market competitiveness of products. Are you still struggling with these issues? The metal surface has a single texture, making it difficult to meet high-end decorative needs; Artificial embossing has low efficiency and poor accuracy, resulting in uneven product quality during mass production; Traditional equipment mold replacement is cumbersome, and facing multi specification orders, one can only passively wait… Don’t let these problems constrain the development of enterprises. The emergence of fully automatic Metal Carbon Steel Stainless Steel Cold Rolling Checker Plate Embossing Machine has brought a new solution to the metal processing industry!

Optional shapes:

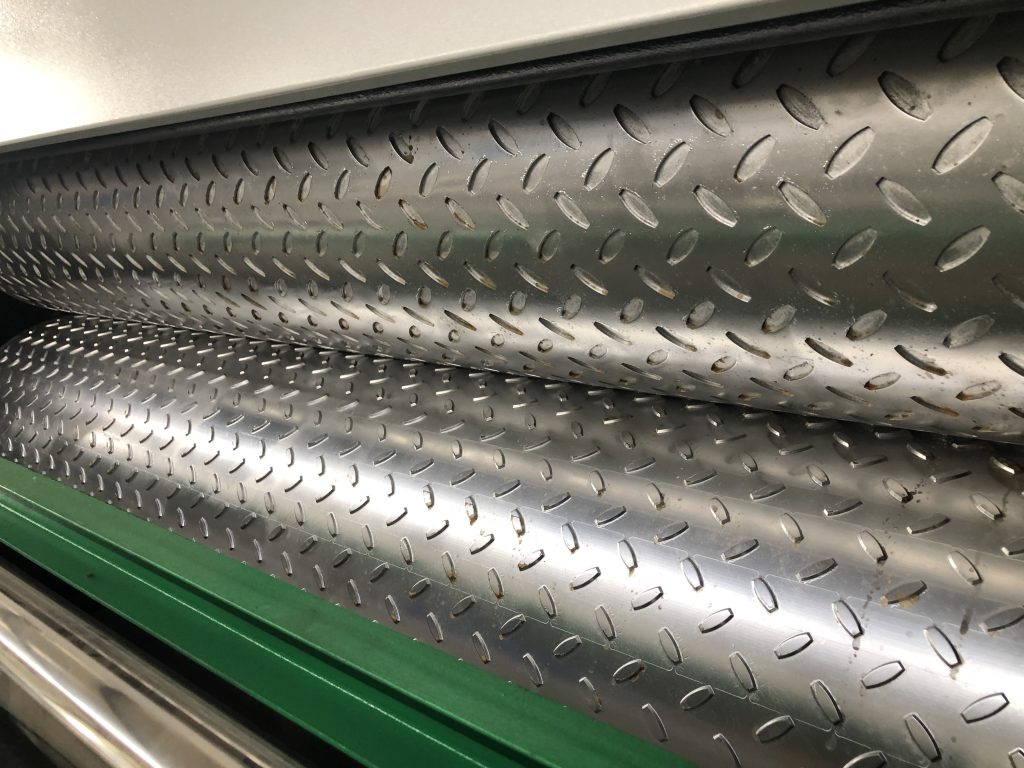

Finished product image:

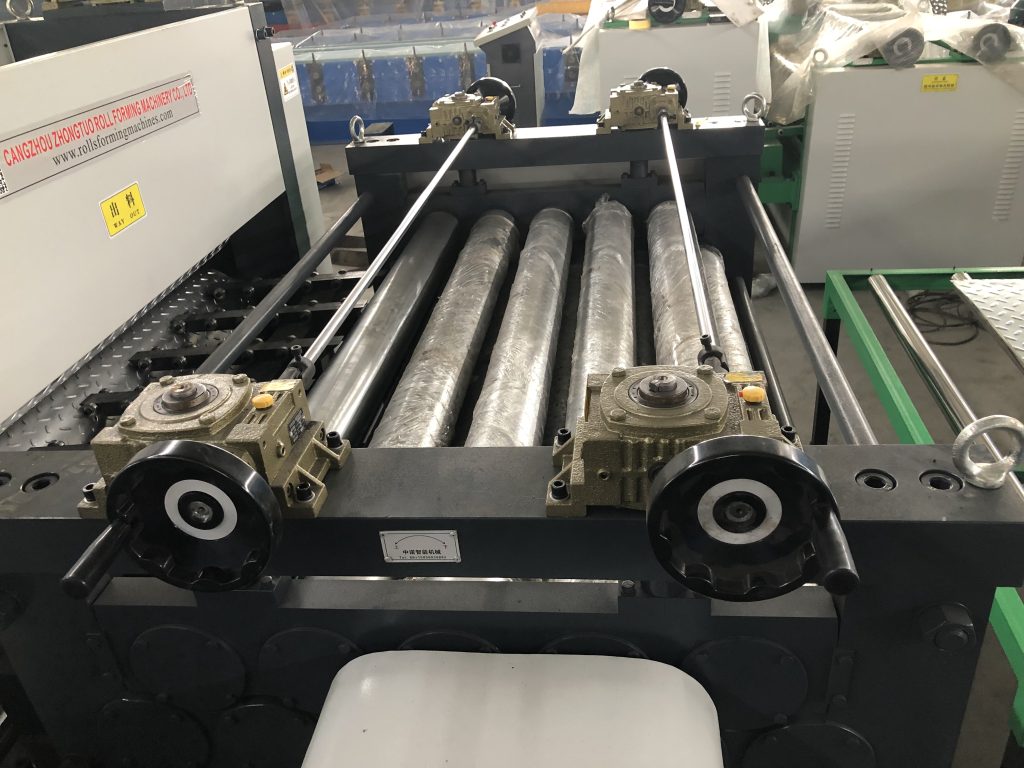

Product Attributes :

1. Roller specifications: DIA450~500mm, width: 1000~2000mm.

2. Take the roll surface hard chromium plating

3. Suitable for pressing plate: 1-6 mm

4.Frame steel plate welded structure, polished, tempering, machining, solid wall plate Q235 90 mm thick

5. Pattern processed by laser engraving.

6. The pattern making: according to the buyer to provide the sample pattern

7. Pressure mode: hydraulic 50~100T.

8. Working speed: 0-10m/min, speed changed by frequency converter .

9. Voltage 380V/50Hz/3PH or customize

10. Safety shield shell

11. Beautiful appearance

Product Introduction

It is a “production engine” that improves efficiency and easily breaks through production capacity bottlenecks. The traditional manual embossing method can only process a small amount of metal sheets per day and is prone to errors due to fatigue. The Metal Carbon Steel Stainless Steel Cold Rolling Checker Plate Embossing Machine adopts servo motor drive and continuous rolling process, which realizes the full process automation from feeding, embossing to winding/cutting for metal coils/sheets such as aluminum, iron, and stainless steel. Its processing speed can reach 10-30m/min, and it can stably produce over 2000 square meters of qualified embossed metal parts in 8 hours, which is more than 5 times more efficient than traditional methods! At the same time, the device supports multi machine operation by one person, greatly reducing manual input, allowing you to deliver quickly and control costs when facing large quantities of orders.

It is a precision master that guarantees quality, creating impeccable metallic texture. The accuracy and texture consistency of metal embossing directly affect the visual effect and durability of the product. This metal embossing machine is equipped with a high-precision PLC control system, combined with alloy embossing rollers that have undergone special heat treatment (with a hardness of HRC60 or above, wear-resistant and wear-resistant), which can accurately control the embossing pressure and speed, ensuring that the texture depth error is ≤ 0.1mm and the texture of the same batch of products is completely consistent. Whether it’s simulated wood grain, stone pattern, three-dimensional geometric pattern, or corporate logo, they can all be presented clearly, and the embossed metal surface is smooth without burrs or deformation, without the need for secondary polishing, directly meeting the high-end decoration and structural use needs, making your product stand out in the market.

It is a “flexible and versatile” tool that can meet diverse needs and easily adapt to production in multiple scenarios. The market demand is changing rapidly. Today, 1.2 mm thick stainless steel embossed plate needs to be processed, and tomorrow, 0.5 mm aluminum embossed coil may be produced; This time we need to suppress the wood grain texture, and next time we may need to customize exclusive patterns. Traditional equipment mold replacement often takes several hours, seriously affecting production progress. This Metal Carbon Steel Stainless Steel Cold Rolling Checker Plate Embossing Machine adopts a fast roller changing design, combined with adjustable embossing parameters (pressure, temperature, speed can be accurately set), replacing embossing rollers only takes 30 minutes, and supports metal material processing with a thickness of 0.1-3mm. Whether it is embossing decorative panels for building exterior walls, anti slip embossing parts for five metal accessories, metal embossing panels for car interiors, or metal decorative strips for the furniture industry, it can be “done in one machine”. In addition, the equipment can also be linked with cutting, laminating and other modules to achieve integrated operations of “embossing+cutting” and “embossing+laminating”, further simplifying the production process.

What is more trustworthy is that we provide full lifecycle service guarantee. Starting from equipment selection, professional engineers will tailor exclusive production plans based on your product specifications, production capacity requirements, and material types; After the delivery of the equipment, free on-site installation and debugging will be provided, and one-on-one operation training will be provided to ensure that your team can quickly get started; In later use, we provide 24/7 online technical support, annual warranty for core components, and timely response to maintenance needs, ensuring worry free production for you.