Angle steel, a critical structural component in numerous industries, including construction, machinery, automotive, and photovoltaics, has a quality and efficiency that directly impacts the progress and cost of the entire project. Are you still struggling with these issues? Manual angle steel processing is inefficient, often resulting in product scrap due to operational errors. Traditional equipment is limited in functionality and struggles to quickly respond to orders for angle steel of varying specifications. Material waste during the production process significantly increases operating costs. Don’t worry! The advent of fully automatic angle steel forming machines offers a completely new production solution!

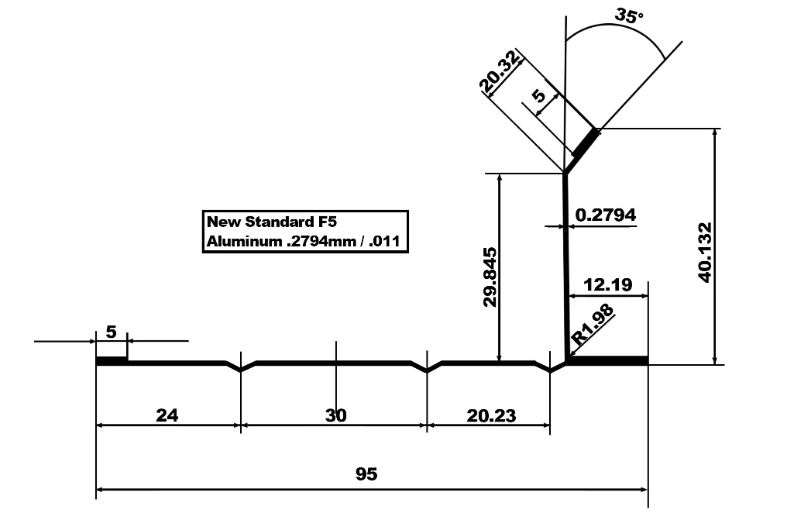

Pattern diagram:

Technical parameter:

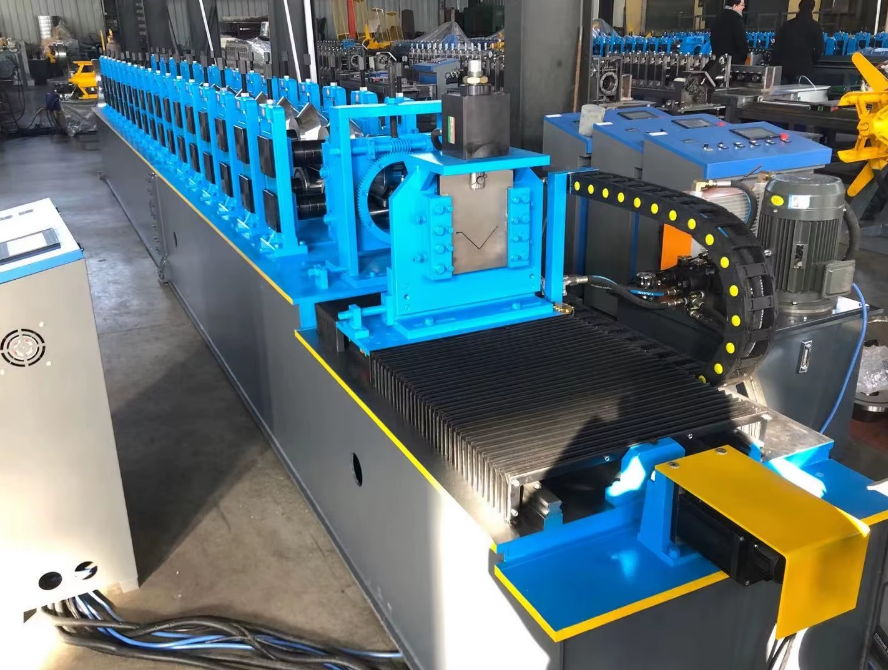

Main roll forming machine:

| Voltage | 380V-3P-50HZ (Or as your request) |

| Drive mode | Chains drive |

| Material of roller | GCr12 Mov |

| Material of shaft | 45# steel with tempering |

| Shaft diameter | Φ 50 mm |

| Numbers of roller | 14 roller stations |

| Main motor power | 5.5+5.5 KW |

| Roll forming speed | 0-45 m/min |

Cutting system:

| Cutter material | Cr12 |

| Power supply | Hydraulic power with tracking cutting |

| Cutting power | 5.5 KW |

Receiving table:

| Quantity | 1 set |

| Length | 3 m |

| Motor power | 0.75 KW |

Hydraulic oil pump station:

| Hydraulic motor power | 3 KW |

| Hydraulic oil | 46# hydraulic oil |

| Cooling system | With cooling fan on it |

PLC control system:

| Language | English/Chinese or as your reuqest |

| Voltage | 380V-3P-50HZ or as your request |

| Length control | Yes |

| Speed control | Yes |

| Operating panel | Have buttons and touch screen |

| PLC brand | DELTA brand |

|

Low voltage electrical apparatus

|

Schneider brand |

| Counter | Omron brand |

A powerful assistant to improve efficiency

This angle steel forming machine is a powerful tool for improving efficiency. Traditional manual angle steel processing can only produce a small number of products after a day’s hard work. However, the fully automatic angle steel forming machine utilizes advanced automation technology to automate the entire process, from uncoiling and automatic feeding to precise forming and cutting to length. With a forming speed of 10-15 m/min, it can consistently produce over 4,000 meters of qualified angle steel in 8 hours, significantly improving production efficiency compared to traditional methods. Furthermore, one person can easily oversee multiple machines, effectively reducing labor input and saving companies significant labor costs, allowing them to easily handle urgent orders.

A “solid backing” to ensure quality.

It also serves as a “solid backing” for quality assurance. The precision of angle steel is crucial for subsequent assembly and use; even the slightest error can cause serious problems. This angle steel forming machine is equipped with a high-precision PLC control system, capable of precisely controlling the feed size to within ±0.5mm, ensuring the exact dimensions of each angle steel. Furthermore, the forming molds used in this machine undergo a special heat treatment, resulting in high hardness and strong wear resistance. This not only ensures precise angles after forming, but also creates a smooth, burr-free surface, eliminating the need for subsequent secondary processing and directly meeting assembly requirements, significantly improving product qualification rates and quality stability.

A “jack of all trades” that can meet diverse needs

This angle steel forming machine also excels in flexibility, making it a versatile tool for meeting diverse needs. Market demands are constantly changing, and companies often need to produce angle steels of varying specifications and styles. Traditional equipment often requires several hours to replace molds, severely impacting production schedules. This angle steel forming machine, however, utilizes a quick mold change design, coupled with a modular workstation layout. Changing molds of different specifications only takes about 30 minutes, significantly reducing equipment adjustment time. Furthermore, it supports integrated punching, cutting, and forming operations. If you need to process round holes, long holes, and the like on angle steel, there’s no need for additional punching equipment. The machine’s built-in precision stamping module can accomplish this task in one go, and the cutting process can be completed without scrapping. Material utilization is increased to over 98%, effectively reducing material waste and lowering the company’s production costs.

Comprehensive quality services

In addition to the superior performance of our equipment, we also provide a comprehensive range of high-quality services. From the moment you inquire about our equipment, our professional engineers will tailor a customized configuration based on your actual production needs, product specifications, and other factors, ensuring the equipment perfectly fits your production process. After delivery, we will arrange for professional technicians to perform on-site installation and commissioning, and provide free training to your operators to ensure they can quickly and proficiently master the equipment’s operation. Throughout the equipment’s subsequent use, we also provide 24/7 online technical support. If you encounter any technical issues, our technicians will provide solutions immediately and ensure the timely supply of spare parts, ensuring a worry-free production process.