Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

GI/GL

|

Thickness:0.4-0.8mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Punching device

|

Punching type

|

High speed rotary punch

|

||

|

4.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

5.Cutting device

|

Cutting type

|

Hydraulic servo motor drived flying shear

|

||

|

6.Power

|

Motor Power

|

7.5KW*2 sets

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

7.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

8.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

9.Forming Speed

|

max 70m/min include punching holes

|

Speed is adjustable according to customer’s request

|

||

Product Description:

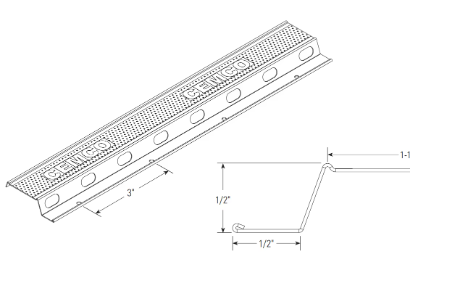

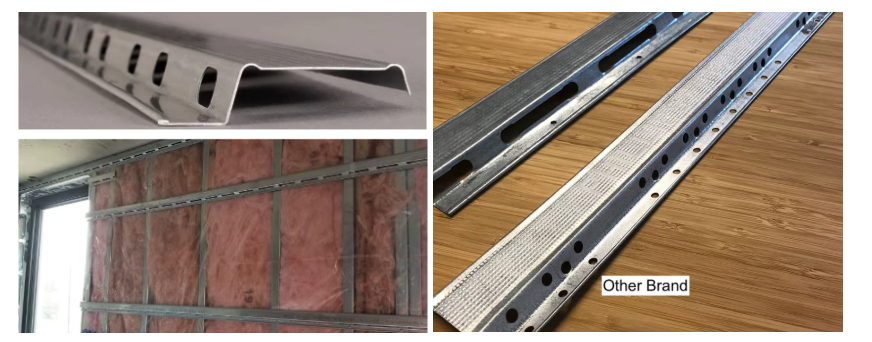

The high speed Resilient Furring Channel roll forming machine is a device designed specifically for drywall construction, mainly used for manufacturing metal bolts and tracks. This equipment can efficiently produce uniformly sized and highly accurate bolts and tracks through rolling forming technology, meeting various length requirements. Its core functions include efficient manufacturing of metal studs and tracks, ensuring uniform size and superior accuracy of each product, and flexible and versatile cutting capabilities, suitable for new construction or renovation projects.

Technical parameters and performance characteristics:

- Production speed:

Using servo motor-driven rolling forming technology, the production speed can reach 45 meters per second, greatly improving work efficiency. - Automation level:

Fully automated operation, precise control through computer, combined with automatic feeding and cutting functions, greatly improves production efficiency while reducing labor costs. - Material adaptability:

The machine is made of high-quality materials to ensure stable operation and excellent durability.

Application areas:

The high speed Resilient Furring Channel roll forming machine is widely used in the production of steel structure buildings, light steel keels, painted keels, card keels and other products. Its efficient and automated characteristics make it an important application in the manufacturing of non load bearing partition wall systems and ceiling keel frames in the field of architecture.

Products Display: