Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.18-0.5mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

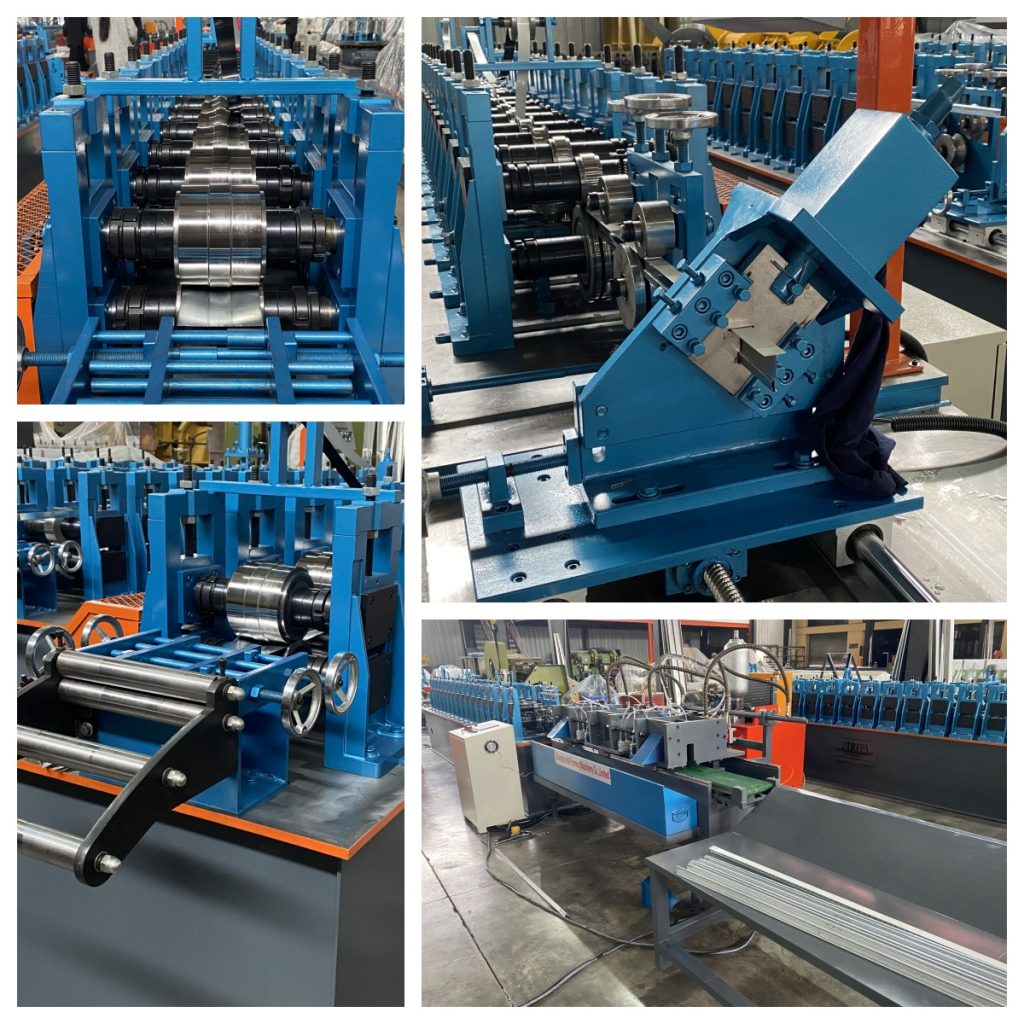

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

70m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

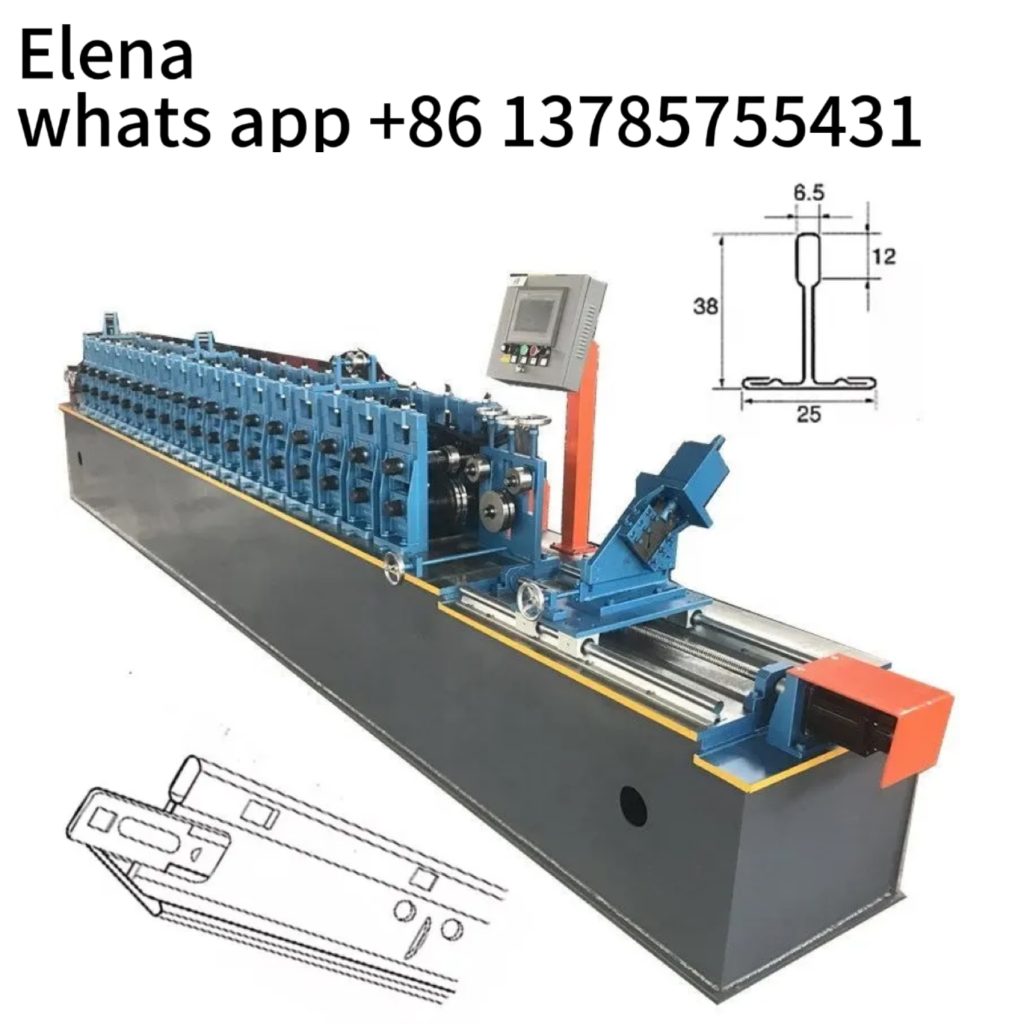

Product Description:

The t grid cross t grid ceiling roll forming machine is a specialized equipment used for producing T-shaped keels, mainly used for ceiling and partition systems in the construction field. The production of metal cross-sectional profiles through cold rolling forming process has the characteristics of high efficiency and high degree of automation. Zhongtuo Machinery adopts a PLC control system, which has the characteristics of high efficiency and high degree of automation. The production speed can reach 6-13 meters per minute. The equipment uses strip steel as raw material and forms T-shaped keels through continuous cold rolling, which is widely used in the production of light steel keels, painted keels and other products.

Features and advantages:

1.Efficient production:

The t grid cross t grid ceiling roll forming machine adopts a fully automatic operation interface, providing multiple language options for easy use by operators. The host adopts Siemens motors, which have smooth transmission and low noise, greatly improving production efficiency.

2.Quality assurance:

Adopting energy storage rapid stamping technology to ensure consistent quality of each hole and head, avoiding errors caused by manual operation, and improving product consistency and stability.

3.Environmental protection and energy conservation:

Using Siemens all copper wire motors, the transmission is smooth, the noise is low, and it meets the requirements of environmental protection and energy conservation.

Application areas:

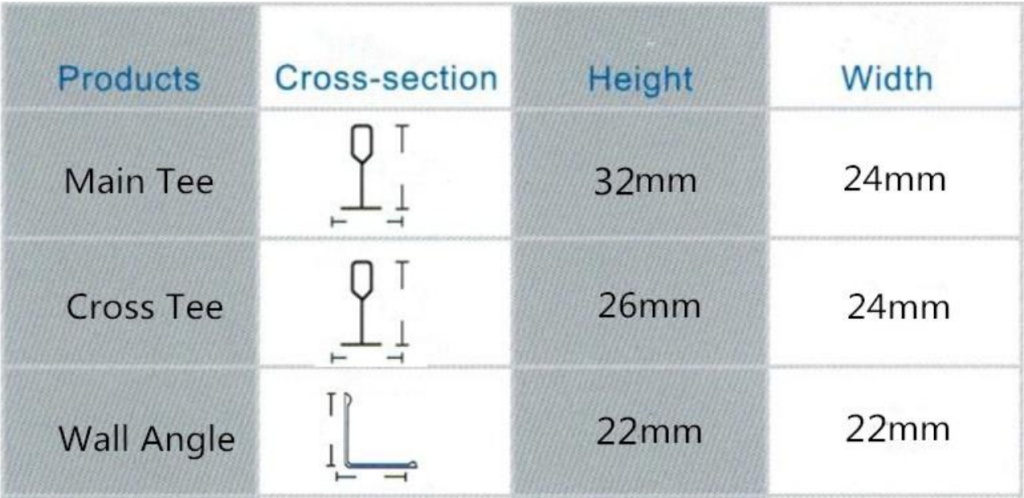

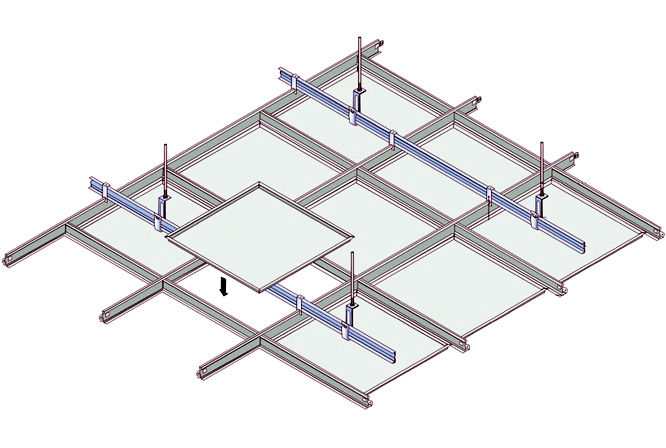

T-shaped keel is widely used in systems such as mineral wool board, gypsum board ceiling, and light steel keel ceiling, and is commonly used in ceiling design in offices, shopping malls, schools, and other places. Due to its stable support, the T-shaped keel can withstand a certain amount of weight and provide a sturdy foundation.