Full automatic standing seam roofing panel roll forming machine is an advanced mechanical device specifically used for producing vertical seam roof panels. It uses metal sheet as raw material and processes the sheet into a unique vertical seam structure through a series of precision machining processes. This device integrates advanced technologies from multiple fields such as mechanical manufacturing, automation control, and materials science, and can meet the diverse needs of different buildings for roof materials. Whether it is a large commercial complex, industrial plant, sports arena, airport terminal and other large public buildings, the products produced by the full automatic standing seam roofing panel roll forming machine can become the ideal choice for roof construction with excellent performance, providing solid and reliable roof protection for various types of buildings.

Equipment features: a concentrated manifestation of excellent performance

The full automatic standing seam roofing panel roll forming machine has many significant characteristics. In terms of processing accuracy, it is equipped with high-precision molding molds and advanced CNC systems, which can control the dimensional errors of roof panels within a very small range, ensuring that each panel can be perfectly assembled and guaranteeing the integrity and sealing of the roof.

Another major feature is its high degree of automation. The equipment adopts a fully automated production process, from the transportation and processing of raw materials to the cutting and stacking of finished products, all of which can achieve unmanned or less human operation, greatly improving production efficiency, reducing labor costs and human operation errors.

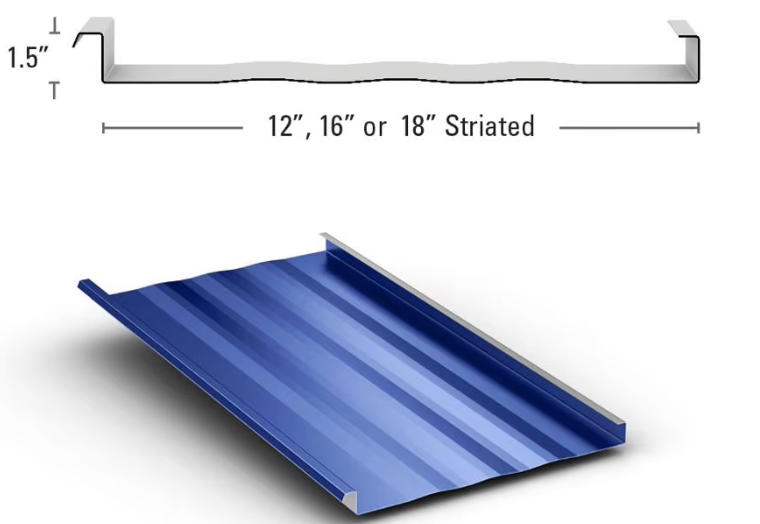

At the same time, the equipment has strong adaptability and can be compatible with various materials of metal sheets, such as color steel plates, aluminum alloy plates, zinc steel plates, etc. It can also flexibly adjust production parameters according to different building design requirements, produce vertical seam roof panels of different specifications and shapes, and meet the construction needs of various complex roofs.

In addition, the equipment operates stably and reliably, using high-quality components and advanced lubrication systems to reduce the occurrence of equipment failures, extend the service life of the equipment, and ensure the continuity of production.

Equipment advantage: showcasing strength beyond tradition

Compared with traditional roof material production equipment, the full automatic standing seam roofing panel roll forming machine has significant advantages. Firstly, the production efficiency is higher. Traditional equipment production methods are cumbersome, with high manual participation and slow production speed. However, the full automatic standing seam roofing panel roll forming machine can produce a large number of roof panels per hour through automated production, which can quickly meet the material requirements of large-scale construction projects and shorten project timelines.

In terms of product quality, the advantages are also very prominent. The traditional production method is prone to problems such as inaccurate size and unstable structure of roof panels, which affect the quality and service life of the roof. The roof panels produced by the full automatic standing seam roofing panel roll forming machine have stronger waterproofing, wind resistance, and durability due to high-precision processing and stable performance. They can effectively resist the erosion of harsh weather and extend the service life of the roof.

From the perspective of cost control, full automatic standing seam roofing panel roll forming machine also has more advantages. Automated production reduces labor costs, and the quality of roof panels produced by equipment is stable, reducing the cost of later maintenance and replacement. Meanwhile, an efficient production mode can also reduce the waste of raw materials, further lowering production costs.

In addition, in terms of environmental protection, the full automatic standing seam roofing panel roll forming machine also performs well. It adopts advanced production technology, has low energy consumption, and generates less waste during the production process, which is in line with the modern concept of green and environmental protection.

Process flow: Perfect presentation of precision manufacturing

The process flow of the full automatic standing seam roofing panel roll forming machine is rigorous and orderly, with every step striving for excellence to ensure the production of high-quality vertical seam roof panels.

The first step is raw material preparation, placing the metal coils that meet the requirements on the feeding rack of the equipment, and smoothly conveying the coils to the next process through an automatic feeding device.

The second step is the leveling process. During transportation and storage, metal coils may experience bending, deformation, and other issues. The leveling device will level the coils to ensure their flatness and lay a solid foundation for subsequent processing.

The third step is molding processing, which is the core link of the entire process flow. After leveling, the board enters the forming machine and, under the action of a series of precision molds, undergoes multiple rolling, bending and other operations to gradually form the prototype of the roof panel with a vertical seam structure. The design of the mold is determined based on the specifications and shape of the roof panel, ensuring that every indentation and bending is precise and error free.

The fourth step is the cutting process. When the roof panel reaches the preset length, the cutting device will accurately cut it according to the set size. The cutting process is fast and smooth, ensuring that the cut is neat and smooth, without affecting the splicing and use of the roof panel.

The fifth step is the output of finished products. The cut vertical seam roof panels are transported to the finished product stacking area through a conveyor device for neat stacking, waiting for subsequent transportation and installation.

The full automatic standing seam roofing panel roll forming machine has become a leader in the field of roof construction with its advanced technology, excellent performance, and perfect process flow. Choosing full automatic standing seam roofing panel roll forming machine will bring efficient, high-quality, and reliable roofing solutions to your construction projects, helping you stand out in the competition of the construction industry.