Work flow of floor deck roll forming machine

https://www.youtube.com/watch?v=xWJj15eT90w

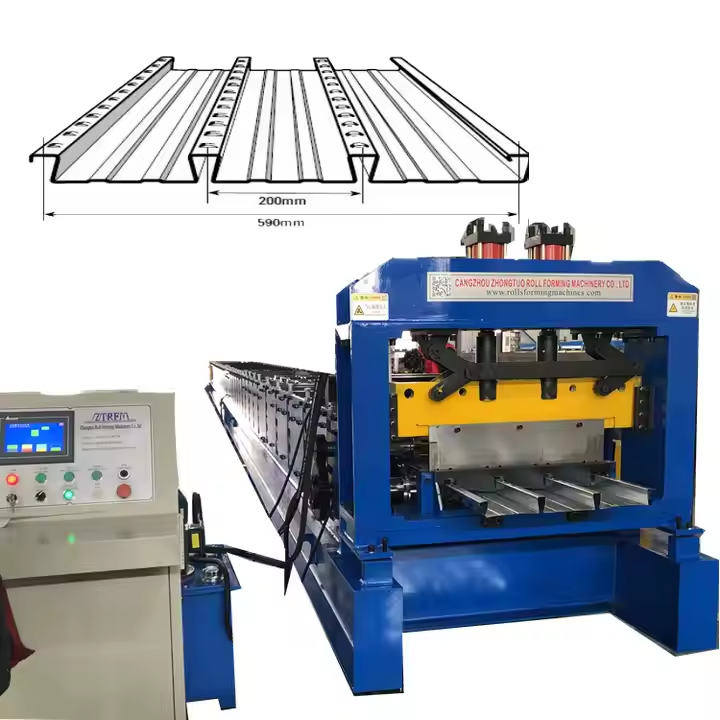

Main introduction of floor decking machine

KLIP-LOK floor deck is a new type of construction formwork, mainly used in housing construction and bridge engineering. It features high strength, high rigidity, good durability and excellent fire resistance, making it one of the commonly used formwork materials in modern construction.

Firstly, KLIP-LOK floor deck has extremely high strength and rigidity, enabling it to withstand large pressure and shear force without easy deformation or damage. Meanwhile, it boasts good durability, ensuring resistance to aging, wear and corrosion during long-term use. Additionally, this formwork exhibits excellent fire resistance, which can effectively prevent the spread of fire and provide better protection for buildings.

Secondly, the installation of KLIP-LOK floor deck is very convenient and efficient, which can effectively shorten the construction period and reduce project costs. At the same time, the closed design of the formwork prevents grout leakage during concrete pouring, guaranteeing the forming effect and quality of concrete. Moreover, the formwork can be customized as needed to meet requirements of different sizes and shapes.

Finally, closed KLIP-LOK floor deck has a very wide range of applications and can be used in various types of housing construction and bridge engineering. For instance, in high-rise buildings, it can be used for floor slab construction; in bridge engineering, it can be applied to the construction of bridge decks, piers and other components. Besides, due to its excellent environmental performance, the formwork is also suitable for green building and sustainable development projects.

In summary, KLIP-LOK floor deck is an outstanding construction formwork material with characteristics such as high strength, high rigidity, good durability and excellent fire resistance. It has a wide application range, being applicable to various housing construction and bridge engineering projects. Meanwhile, its installation is convenient and fast, which can effectively shorten the construction period and reduce project costs. Therefore, closed KLIP-LOK floor deck is one of the indispensable important materials in modern construction.

The main parameters of the machine

|

1.Formed Material

|

PPGI,PPGL

|

Material Thickness:24/26 Gauge (0.3-0.6 mm) Width:43inch(1092mm)

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

26 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

350mm H Beam Structure, With 18mm Welded Steel Middle Support Plate.

|

|||

|

Drive

|

gear and Double Chain transmission

|

|||

|

Dimension(L*W*H)

|

1.3m*1.65m*1.5m

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||