Work flow of Double Layer Tile Iron Sheet Roofing Tile Making Roll Forming Machine

Double Layer Tile Iron Sheet Roofing Tile Making Roll Forming Machine Operations

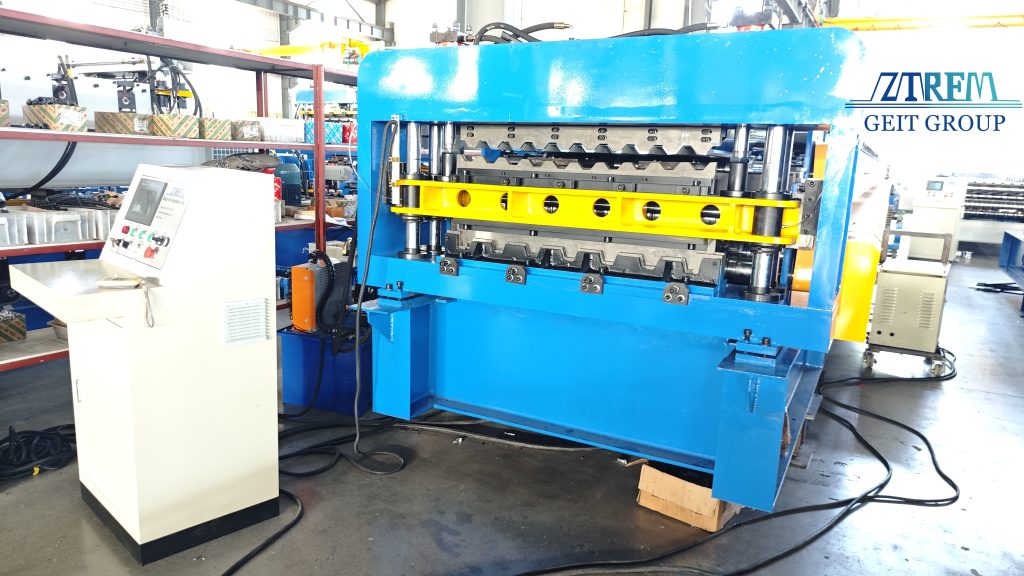

1. Overview and Main Components

The double layer color steel tile machine achieves efficient integration of two models, with a scientific structure and neat appearance. It offers advantages like space-saving and easy operation, making it especially suitable for users with limited site space or those needing on-site construction.

The equipment mainly consists of a feeding and guiding platform, a forming main machine, a forming and cutting device, a hydraulic station, and a computer control system. Switching between the upper and lower layers is simple: each layer can be controlled separately via the conversion button on the electric control cabinet, and power can also be controlled independently for each layer through a clutch. Optional configurations include ordinary uncoilers and hydraulic uncoilers, with specific models of the upper and lower layers customizable to customer requirements.

2. Steel Drag Chain Details and Performance

The machine tool steel drag chain of the double layer tile press is primarily composed of chain plates (high-quality chrome-plated steel plates), support plates (extruded aluminum alloy), and shaft pins (alloy steel), etc. These components ensure no relative movement or distortion between cables/rubber pipes and the drag chain.

The chain plates, after chrome plating, feature a novel design and reasonable structure, with high flexibility, strong rigidity, and resistance to deformation. They are easy to install, reliable in use, and simple to disassemble. Notably, high-strength wear-resistant materials are used, and the shaft pins are made of alloy copper, which enhances the product’s wear resistance—making the drag chain bend more flexibly, with lower resistance and less noise—ensuring it remains free from deformation and sagging during long-term use.

Performance parameters of the steel drag chain:

– Maximum moving speed: 40 meters per minute

– Noise sound pressure level: no more than 68 decibels

– Safe service life: no less than 1 million times (reciprocating)

3. Purchasing Key Points for Double Layer Tile Press

– Check if there are welds at both ends of the solid shaft.

– The equipment’s weight can help determine whether components are solid or hollow.

– The quality of the tile press cannot be judged solely by whether the shaft is solid or hollow; some solid-shaft equipment may not meet quality standards, so a comprehensive inspection is necessary.

– Examine the frame material: high-quality frames typically use more abundant materials.

– Note the thickness of vertical plates on both sides: ordinary single-layer tile presses usually have 12mm vertical plates, while double layer ones have 14mm. High-quality double layer presses often use U-shaped vertical plates, while ordinary ones use strip-shaped vertical plates.

– Chains vary in quality, with specifications of 1 inch and 6 inches.

The main parameters of the machine

| Length of the main part | About 9000*1650*1500 mm |

| Weight of main part | 7 tons |

| Voltage | 380 v 50 hz 3 phase |

| Roller fixer | Middle plate 20mm thickness |

| Frame | 400 H-beam steel welded |

| Drive mode | Chain |

| Material of rollers | 45# steel, surface hard chromium plating. |

| Material of shafts | 45# steel |

| Diameter of shafts | φ 80 mm |

| Number of rollers | 13 rollers (C8) 17 rollers (C21) |

| Main power | 7.5 kw |

| Material thickness | 0.3-0.8mm |

| Forming speed | 8-20 m per minute |

Recommend related machine: