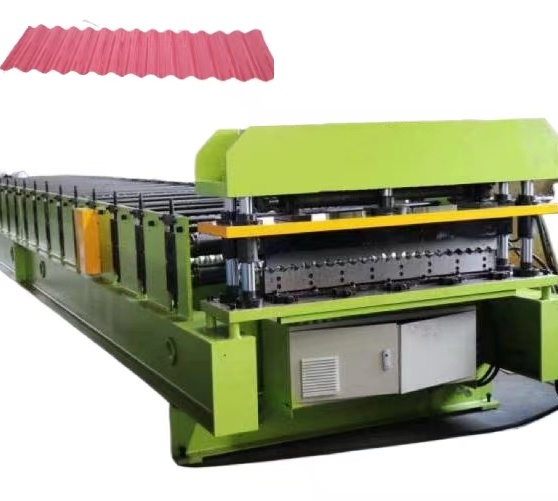

Work flow of Corrugated Roof Sheet Roll Forming Machine

https://www.youtube.com/watch?v=HoYD5j-KxQU

The Critical Role of Corrugated Roof Tile Equipment in Construction

In the field of construction engineering, the processing quality of corrugated roof tiles directly affects the structural stability and aesthetic integrity of building roofs. As the core carrier in the production process, roof tile equipment plays a vital role in determining performance and precision. Among them, curved corrugated roof tile equipment, with its professional processing capabilities for corrugated tile, has become a key device for adapting to various special-shaped roof designs, playing an irreplaceable role in modern building roof system construction.

Zhong Tuo Corrugated Roof Tile Equipment: Specialized for Arc-shaped Tile Processing

Zhong Tuo curved corrugated roof tile equipment is a specialized device integrating processing, forming, and auxiliary installation of curved corrugated roof tiles. It is designed to address industry pain points such as insufficient processing precision and limited adaptability of arc-shaped tiles. Equipped with a precision cutting and multi-curvature forming system, driven by servo motors and with digital parameter settings, it can accurately realize one-time forming from flat base materials to tiles of different radii (such as 1/4 circle, 1/6 circle, etc.). It can flexibly match the arc structures of various building roofs, including sloped roofs, domes, and arched roofs, ensuring that the fitting error between tiles and the roof base is controlled at the millimeter level. This fundamentally avoids potential leakage risks that may occur in traditional manual processing.

Meanwhile, the automated production mode of the equipment increases the single-shift production capacity by more than 300%, significantly reducing labor input in links such as manual handling, positioning, and cutting. Moreover, through standardized production processes, it ensures the dimensional consistency and surface flatness of each tile, significantly improving the overall quality of roof projects.

Core Components: Rigorous Material Selection and Craftsmanship

As a representative of fully automated roof tile forming equipment, Zhong Tuo curved corrugated roof tile equipment embodies strict professional standards in the material selection and craftsmanship of core components:

The roller components of the forming machine are made of high-quality 45# carbon structural steel as the base material.

After quenching and tempering, this steel has excellent comprehensive mechanical properties, with a hardness of HB220-250, sufficient to withstand the mechanical load of long-term high-pressure forming operations. On this basis, the roller surface undergoes precision chrome plating, with a coating thickness controlled at 0.05-0.1mm.

This not only makes the surface finish reach a mirror-level standard of Ra0.8μm or lower but also achieves double protection for the rollers through the inert chemical properties and high hardness (Hv900-1100) of the chrome plating layer.

On one hand, it effectively resists erosion from base material debris and moisture in the air during processing, preventing rust; on the other hand, it significantly improves wear resistance, extending the service life of the rollers to more than 3 times that of traditional carbon steel rollers.

More importantly, the smooth chrome-plated surface can minimize the friction coefficient with processing materials such as color steel plates and galvanized plates,

avoiding damage to the material surface coating or scratches caused by contact wear, thus ensuring the appearance integrity and weather resistance of finished tiles.

Cutting Section: High Precision Guaranteed by Intelligent Control

In the product cutting section, the equipment adopts a PLC programmable logic control system combined with high-precision grating ruler positioning technology to achieve full closed-loop cutting control.

Operators can preset parameters such as cutting length and quantity through the touch screen.

The system collects feeding speed and position information in real-time and makes dynamic adjustments, stabilizing the cutting precision within ±0.3mm, which is far higher than the industry standard of ±1mm.

This automated control mode not only simplifies the operation process (only 1-2 operators are needed to complete the entire line production) but also fundamentally eliminates cumulative errors caused by manual measurement and cutting.

It provides precise dimensional guarantee for the rapid splicing of corrugated roof tiles in large-scale production, and is especially suitable for efficient construction of large-area curved roof projects such as large factories, gymnasiums, and exhibition halls.

The main parameters of the machine

| Feeding device | One set guiding roller |

| Steel plate welded platform to carry the sheet and feed into roll forming system | |

| Feeding width is adjustable with the handle wheels | |

| Rolling shaft | Shaft material:45# STEEL |

| Shaft diameter: 75 mm | |

| Tempering treatment to prevent deformed and improve hardness | |

| Roller | 45# steel, hard chromed treatment |

| Rolling station | 15 rollingstations |

| Work speed | 0-20m/min |

| Machinestructure | Steel plate welded structure |

| Machinebasic frame | 350# H steel welded |

| Work power | 5.5 kw |

| Rolling spacer | Anti rusty treatment |

| Pull rod | Anti rusty treatment |

| Transmission | By Chains with cover |

| Noted: please fill the lube in case the chains getting dry |