The Metal Steel Aluminum PPGI Coil Cut to Length Line and Slitting Machine serves as the core machinery for metal coil processing, achieving the full-process transformation from wide-width coils to precision strips/plates through the coordinated operation of longitudinal slitting and cross-cutting. Its technical essence lies in integrating four major functional modules—uncoiling, leveling, shearing, and stacking—to form a closed-loop processing chain.

1.Longitudinal slitting:

Multiple parallel cuts are made along the length of the material, dividing the coil into narrow strips of specified width (e.g., 0.1-12mm thickness range), suitable for raw material preparation of precision components such as motor stators and rotors, and transformer cores.

2.Cross-cutting to fixed dimensions:

Perform lengthwise cutting along the width direction to produce flat plates and automatically stack them, meeting the stringent requirements for dimensional accuracy (±0.3mm) and surface quality in applications such as automotive body panels and home appliance panels.

3.Composite Integration:

High-end models integrate dual functions into one system, achieving one-stop processing from coil material to strip material to sheet material through an EPC automatic edge alignment system and servo feeding mechanism, significantly enhancing production line flexibility.

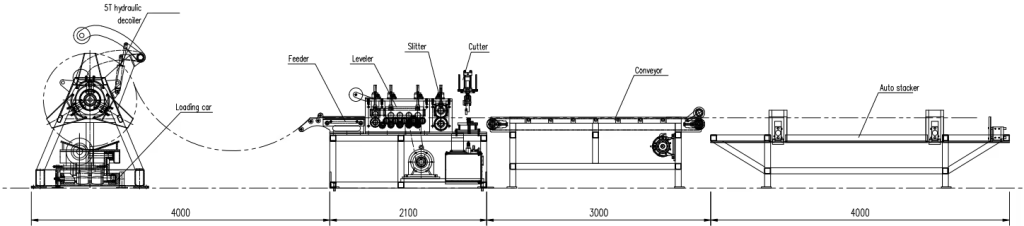

Working flow:

Uncoiling → Feeding material into machine →Leveling →Slitting (Waste rewinder) →Cutting(Optional) → Conveyor→Auto stacker →Tension stand→Recoiler

Main components:

| Item | Description of Item | Unit | Quantity |

| 1 | Hydraulic decoiler with loading car | set | 1 |

| 2 | Leveling & slitting & cutting device | set | 1 |

| 3 | Waste rewinder | set | 2 |

| 4 | Conveyor | set | 1 |

| 5 | Auto stacker | set | 1 |

| 6 | Tension stand | set | 1 |

| 7 | Recoiler with unloading car | set | 1 |

| 8 | Control system | set | 1 |

| 9 | Hydraulic system | set | 1 |

Technological Breakthroughs and Performance Advantages

1.Dual improvement in accuracy and efficiency

• Shearing Precision: Utilizing high-precision alloy steel cutting tools and a closed-loop control system, the transverse shearing dimensional accuracy is maintained within ±0.3mm, while the longitudinal slitting width deviation is ≤0.5mm, ensuring consistent raw material blanks for stamping parts.

•Speed breakthrough: Servo drive and stepless speed regulation technology enable a longitudinal cutting speed of 200 m/min, with transverse cutting line speed covering the range of 40-120 m/min, achieving over 30% efficiency improvement compared to traditional equipment.

2. Material Adaptability Expansion

The equipment is compatible with a wide range of metal materials, including cold-rolled carbon steel, silicon steel, stainless steel, aluminum plates, galvanized plates, and more. It features optimized shearing processes specifically for thin materials such as silicon steel sheets and tinplate, effectively reducing burrs and deformation.

3. Intelligence and Stability Upgrades

•Fully automated control: The touch screen HMI and PLC system enable parameter presetting and self-diagnosis of faults, reducing the need for manual intervention.

•Structural Reliability: The heavy-duty bearings and CNC machining frame ensure long-term high-load operation, extending equipment lifespan by 40% while significantly reducing noise and failure rates.