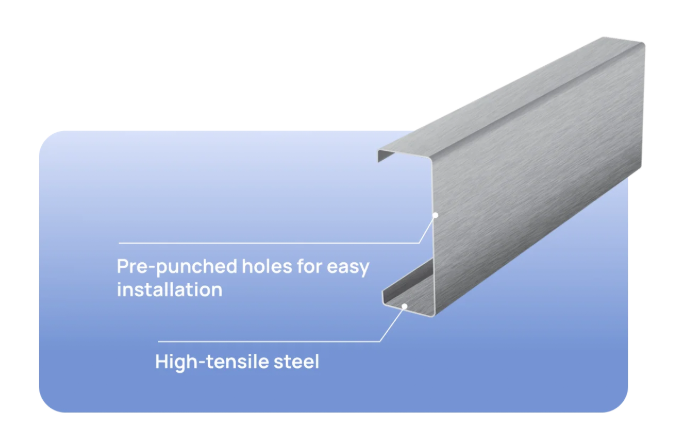

Fully Automatic C Purlin Roll Forming Machine (Gearbox Type) is an automated cold bending equipment used for producing C-shaped steel (also known as C-shaped purlins), widely used in the manufacturing of main load-bearing structures in industrial and civil buildings. This equipment uses continuous roll forming technology to process steel coils into C-shaped steel components with reasonable cross-sectional shapes and high load-bearing capacity.

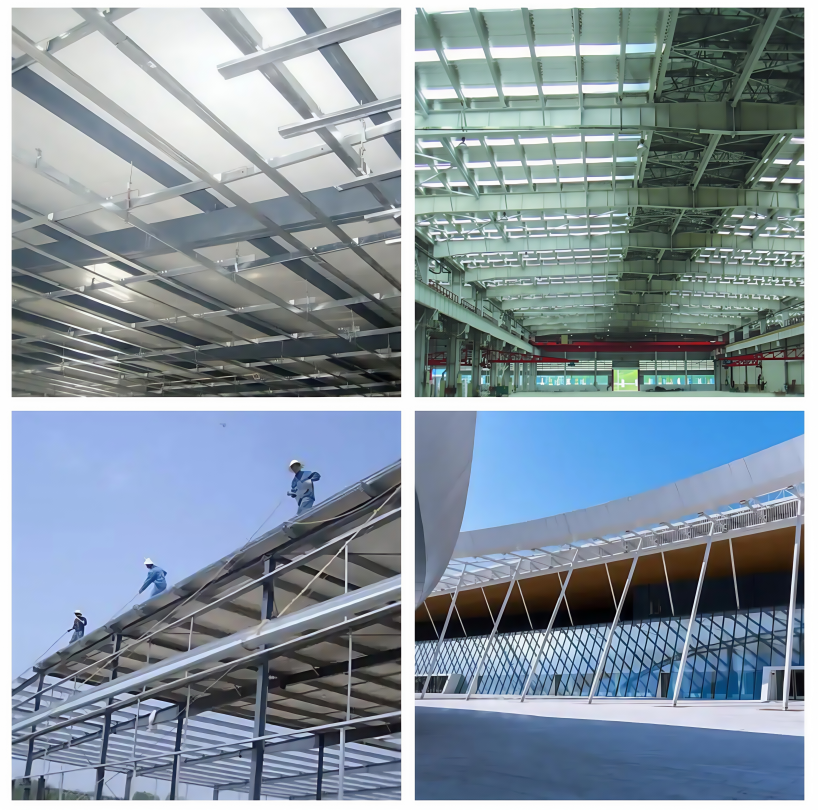

Application scenario:

1.Steel structure construction field

The finished products produced by C-shaped steel machines are widely used in the main structures of large and medium-sized industrial and civil buildings, such as factories, warehouses, locomotive depots, exhibition halls, sports venues, cinemas, etc. C-shaped steel can serve as key load-bearing components such as roof purlins, wall beams, crossbeams, and columns, providing stable support. It has good flatness and high strength, which can effectively improve the safety and construction efficiency of buildings.

2.Prefabricated buildings and photovoltaic brackets

With the development of green buildings and new energy, the application of C-shaped steel in prefabricated buildings is increasing day by day. Meanwhile, in solar power generation systems, C-shaped steel is widely used in the manufacturing of photovoltaic brackets, which have good corrosion resistance and structural stability, and are suitable for long-term outdoor use.

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Analysis of the core advantages of the machine

1、 Efficient and precise production capacity

(1)Automated production process:

Integrated with automatic feeding, pressing, and cutting functions, it can output 6-8 meters of finished products per minute, increasing efficiency by more than 40% compared to traditional processes.

(2)Precision machining capability:

Using servo system and PLC control module, the dimensional error is strictly controlled within ± 0.1mm to ensure that the components are assembled tightly and seamlessly.

(3)Diversified processing support:

Supports various hole types such as circular holes, elliptical holes, and square holes, and can achieve special processes such as oblique punching and side punching to meet complex engineering requirements.

2、 Stable and durable equipment performance

(1)High strength structural design:

The fuselage frame is made of high-strength steel, and the key transmission components are made of alloy materials, which can operate stably in high-strength production environments for a long time.

(2)Low failure rate guarantee:

Through precision machining and strict quality inspection, the equipment can maintain stability under complex working conditions, effectively reducing maintenance frequency.

(3)Energy saving and consumption reducing features:

Optimize the transmission system and material utilization rate, significantly reducing energy consumption and waste generation in the production process.

3、 Flexible and adaptable modular design

(1)Quick changeover capability:

Supports mold replacement within three minutes, easily meeting the processing needs of C-shaped steel with different thicknesses and sizes.

(2)Multi scenario compatibility:

Suitable for 0.8mm-3.0mm steel plates, galvanized plates, and stainless steel plates, widely used in light steel villas, heavy-duty shelves, new energy vehicle frames, and other fields.

(3)Customized solution:

Provide non-standard size customization services, combined with professional structural calculation support, to ensure that the solution meets national standards.