The Metal Steel C Shape Purlin Making Machine for Roof Structure is an automated equipment used for continuous cold bending production of C-shaped steel, widely used in the field of steel structure construction. It can efficiently produce C-shaped steel purlins with uniform specifications and stable performance. This type of equipment integrates processes such as feeding, leveling, punching, forming, and cutting, achieving fully automated assembly line operations from steel coils to finished products.

The Metal Steel C Shape Purlin Making Machine for Roof Structure usually consists of the following core components:

1.Passive loading rack: used to carry steel coils and achieve smooth feeding.

2.Leveling device: eliminates the bending of raw materials during transportation and storage, ensuring the flatness of the sheet before entering the forming roller.

3.Punching device: Automatically complete multi-point punching on C-shaped steel according to design requirements to meet subsequent installation and connection requirements.

4.Forming system: The core part of the entire equipment is to gradually bend the flat plate into a “C” shaped cross-section through multiple passes of rolling mills.

5.Cutting device (flying saw): an automatic flying saw driven by hydraulic or pneumatic power, which precisely cuts finished products according to the set length.

6.Hydraulic station and electrical control system: provide power and integrate PLC control to achieve full process automation operation and parameter adjustment.

Application scenarios

• Roof purlins and wall beams of industrial plants, warehouses, and garages;

• The load-bearing structures of large-span buildings such as exhibition halls, sports venues, cinemas, etc;

• Mechanical manufacturing fields such as photovoltaic bracket systems, equipment frames, and guide rails;

• Stainless steel C-shaped steel is also commonly used in industries such as food processing and medical devices in humid or corrosive environments.

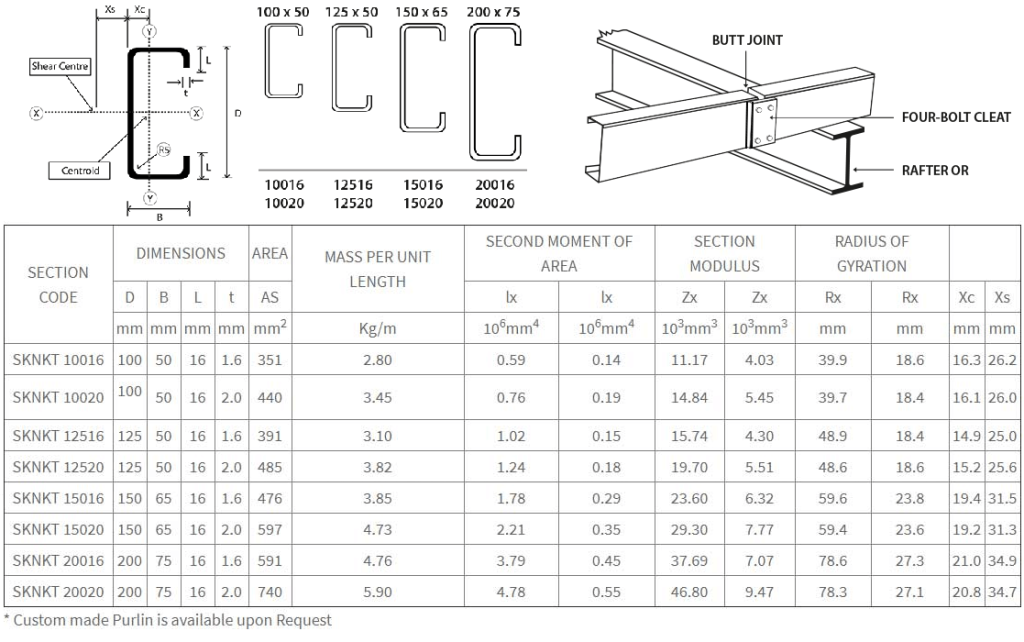

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Core advantage: redefining the production standards for C-shaped steel

Our machine breaks through traditional production bottlenecks and integrates five core processes: uncoiling, leveling, punching, forming, and cutting. It achieves full process automation from raw materials to finished products, completely bidding farewell to the inefficiency and complexity of traditional manual bending and welding.

1. Millimeter level accuracy, building a solid foundation for engineering

Adopting PLC intelligent control system and high-precision servo drive, combined with alloy steel (GCr15) rollers that have undergone overall quenching treatment in a salt bath furnace, the quenching hardness reaches HRC58-62, and the quenching depth is 8mm, ensuring stable and controllable forming process.

2. Efficient mass production, solving delivery problems

The production speed of the equipment can reach 8-25 meters per minute, and only 1-2 people are needed to monitor and operate a single device. The maximum output of a single shift (8 hours) can reach 3000 meters, with a daily output of 15-20 tons, which is 40% -60% more efficient than traditional processing equipment.

3. Diversified adaptation, covering the needs of all scenarios

Through modular design and new docking type adjustment steel sleeves, the equipment can flexibly adapt to the production of various specifications of C-shaped steel with a width of 60-350mm and a thickness of 1.2-3.5mm. By replacing the rollers or adjusting the spacers, the model can be quickly switched without the need for additional specialized equipment.

4. Energy conservation and consumption reduction, enhancing profit margins

The cold bending process has no cutting edge waste throughout the entire process, and with the intelligent fixed length cutting system, the material consumption can be accurately controlled, greatly improving the utilization rate of steel. Compared with traditional processing methods, the annual steel loss can be reduced by more than 20%.

5. Hardcore configuration: a solid guarantee of quality and durability

We always adhere to the production philosophy of “quality first”, striving for excellence in every detail from core components to overall architecture. The equipment base is made of 320 I-beam or 350H steel, and the body is stable and sturdy, which can effectively resist the vibration and impact during the production process.