Under the wave of industrialization in architectural decoration, efficient, precise, and stable processing equipment is the core competitiveness for enterprises to seize market opportunities. As a key equipment in the field of light steel keel processing, ZTRFM Full Automatic Metal Furring Channel Forming Machine Omega provides efficient and convenient solutions for industries such as building materials production and construction decoration with its unique forming process and excellent performance. It has become the preferred equipment for many enterprises to upgrade production capacity and improve quality.

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.4-0.8mm

|

||

|

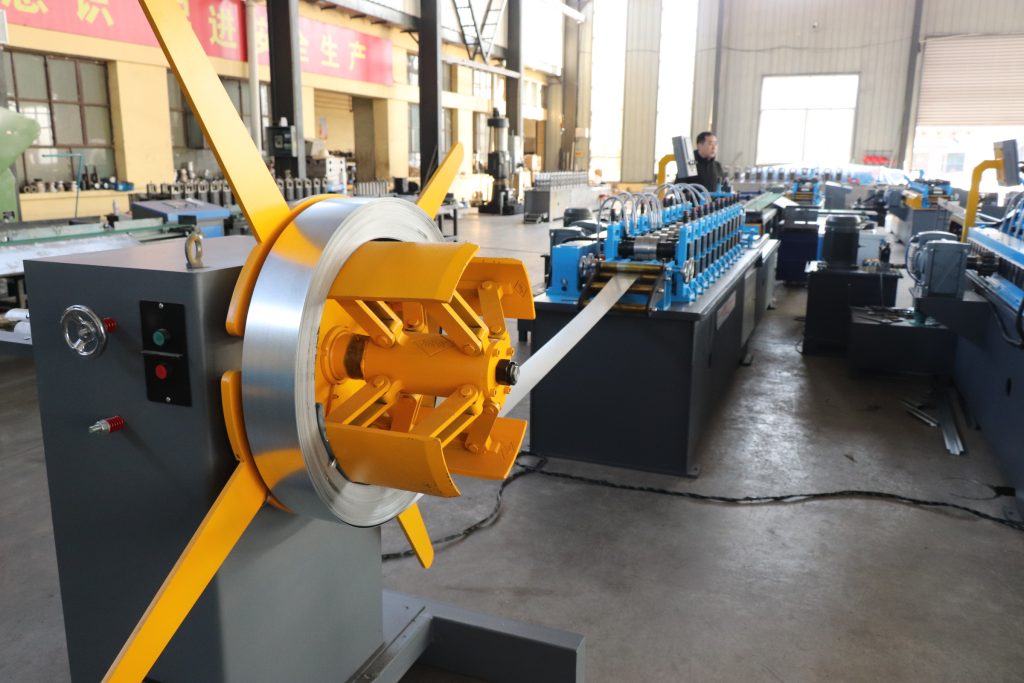

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

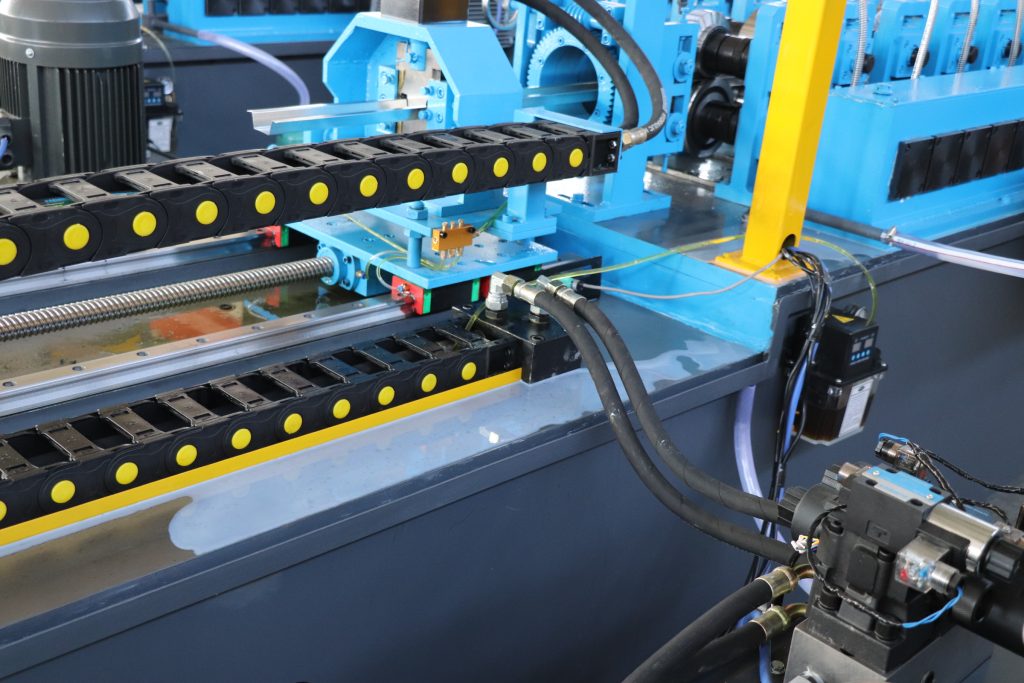

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

40-45m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

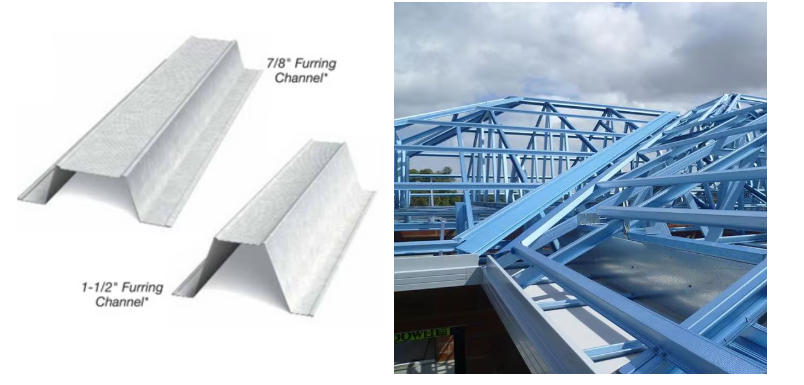

Multiple application scenarios: Global coverage, adapted to the construction needs of multiple industries

Based on the product characteristics of lightweight, high-strength, and easy installation of hat type keel, the application scenarios of ZTRFM Full Automatic Metal Furring Channel Forming Machine Omega have comprehensively covered multiple fields such as building decoration, industrial manufacturing, and new energy, becoming a core processing equipment across industries. The specific application scenarios are as follows:

• Architectural Decoration Field: Mainstream Demand Scenarios

• Industrial and transportation sectors: structural support core

• New Energy and Agriculture: Featured Adaptation Scenarios

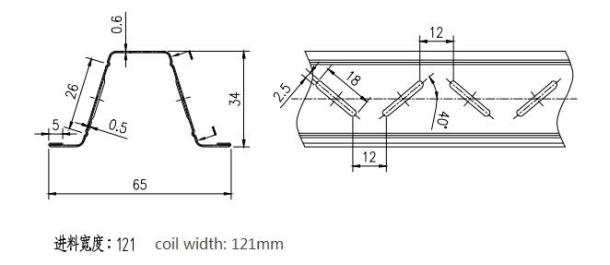

Profile drawing as below:

Core competitive advantage: multidimensional leadership, creating core value for the enterprise

Compared with traditional keel processing equipment, ZTRFM Full Automatic Metal Furring Channel Forming Machine Omega have significant advantages in precision, efficiency, stability, cost-effectiveness, etc., fully meeting the production needs of enterprises and creating greater value for users:

1. High precision molding, excellent product quality

The equipment adopts a multi pass cold bending forming process and a precision CNC system, with a forming accuracy controlled within ± 0.1mm. The flatness error of the keel surface is as low as 0.08mm, and the crack free rate at right angle bends reaches 100%. The processed hat shaped keel has a clean and flat appearance, with strength far exceeding industry standards. Its bending strength can reach over 300MPa, and the product qualification rate has been increased to 99%. Whether it is for domestic engineering applications or export needs, it can easily meet quality requirements.

2.Efficient and energy-saving, dual optimization of production capacity and cost

The equipment is equipped with a variable frequency speed regulating motor, which can flexibly adjust the operating speed according to the thickness of raw materials and production needs. The molding speed is 40% higher than traditional equipment, and the daily production capacity can reach more than 1200 meters. At the same time, the variable frequency drive design reduces energy consumption by 25% compared to traditional equipment, and with optimized molding processes, the material utilization rate is increased to 98.5%, effectively reducing raw material waste and lowering production costs for enterprises.

3. Stable and durable, with extremely low operation and maintenance costs

The key components are made of high-quality materials and imported brands. The rollers are heat-treated with hard chrome plating, and the blade has a service life of over 1 million times. The equipment has been running continuously for over 8000 hours without any faults, with an average annual downtime of less than 5 hours. The comprehensive utilization rate of the equipment is over 95%.

4. Flexible adaptation to meet customized needs

The equipment supports modular mold replacement and can quickly switch between different specifications and materials of cap type keel production. It is compatible with various raw materials such as cold-rolled steel, galvanized steel, stainless steel, aluminum alloy, etc., meeting the customized production needs of multiple industries such as building decoration and industrial manufacturing. Whether it is standard specification products or customized special sizes, efficient mass production can be achieved, helping enterprises quickly respond to market changes.