Faced with the differentiated needs of different industries such as construction, transportation, energy, and communication, our Easy Operation Customized Cable Tray Roll Forming Machine with Punching Holes has strong material adaptability and specification compatibility, and can flexibly produce various specialized trays to fully meet the requirements of complex scene applications.

-Multi material compatibility:

suitable for complex working conditions: supports processing of various raw materials such as galvanized steel strip, Q195/Q235 carbon steel, aluminum alloy, nickel based alloy, fiberglass, etc. The material thickness adaptation range is 0.5-3.0mm, and can produce specialized cable trays that are corrosion-resistant, high-temperature resistant, lightweight, explosion-proof, etc. according to different scene requirements.

-Full specification coverage:

meeting diverse needs: can produce various types of cable trays such as trough, tray, step, and combination, with a width adaptation range of 50mm-1200mm and a height of 25mm-300mm. It can be customized to produce special functional cable trays with large spans (maximum span of 6m), fire resistance, fire resistance, electromagnetic shielding, etc.

-Modular design, balancing stability and flexibility:

The equipment frame is made of Q345B structural steel welded together, which has undergone aging treatment to eliminate internal stress and improve deformation resistance by 20% compared to the industry average. The core transmission components use high-precision gears and servo motors, which run smoothly with low noise and extend the service life to more than 10 years. Simultaneously optimizing the body structure, reducing weight by 15%, balancing production stability and site mobility, and adapting to different sizes of factory layouts.

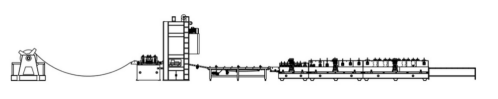

Pattern diagram:

working flow :

Punch press process flow: Active feeding — Leveling servo feeding — Punch press (punching, cutting) — Conveying platform — Forming — Discharge

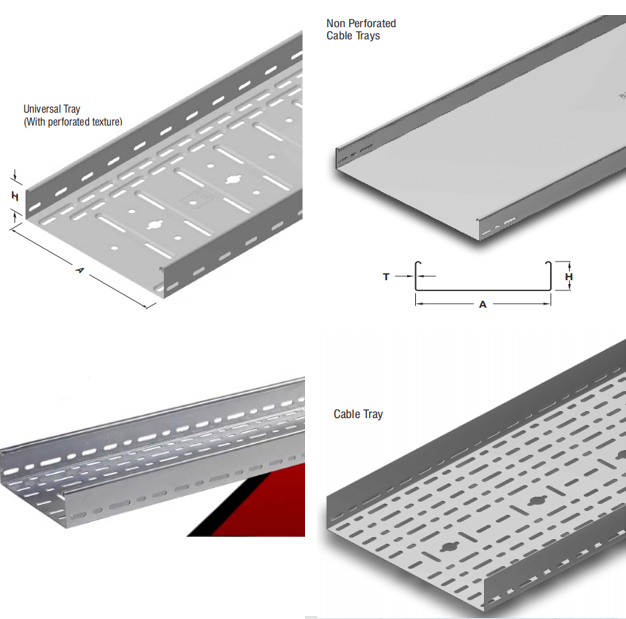

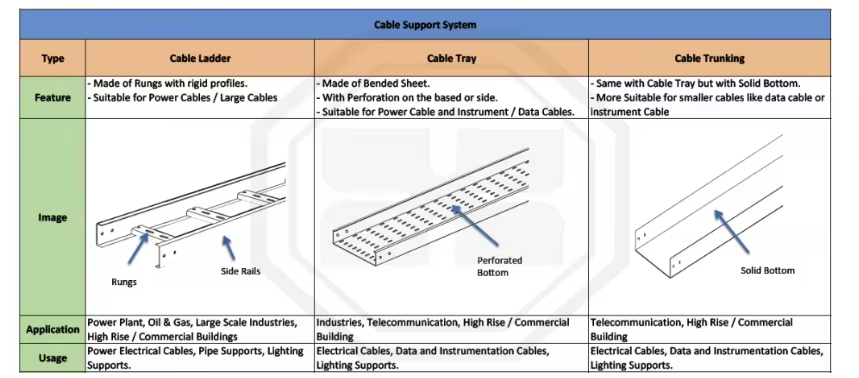

Common types and characteristics:

• Slot type (fully enclosed):

Like a covered “slot”, it has good dust prevention and interference shielding effects, suitable for sensitive cables such as computers and communications, but relatively poor heat dissipation.

• Tray type (heavy-duty type):

The bottom plate is wide, the load is large, the heat dissipation is good, and it is suitable for laying a large number of power cables. It is a common choice in industries such as petroleum and chemical.

• Cascade type (lightweight):

Lightweight and breathable like a ladder, with obvious advantages in heat dissipation and cost, suitable for general power cable laying.

• Network format (new type):

excellent ventilation and heat dissipation, environmentally friendly and recyclable, good earthquake resistance, it is the development trend of high heat dissipation demand scenarios such as data centers in the future.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:200-1130 mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

7T

|

||

|

3.Main body

|

Roller station

|

22 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

35×1.5×1.6m

|

|||

|

Weight

|

About 60KW

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

5-10m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Core functions and structural characteristics

1.Support and protection:

Overhead cables are like sturdy “shelves” to avoid wear and compression, especially in harsh environments such as outdoors and chemical plants. The rainproof and corrosion-resistant cover plate design can effectively protect the internal cables.

2.Flexible configuration:

Modular design allows for easy adjustment of length, width, and height to meet different on-site requirements.

3.Layered management:

There is usually a clear layered design that can classify and lay power cables, control cables, etc. to avoid interference and facilitate maintenance.