Today, with the wave of prefabricated construction sweeping the world and the continuous deepening of green building materials policies, light steel keel, as the core component of building decoration and structural support, directly determines the production efficiency and quality accuracy of engineering quality and enterprise competitiveness. The traditional production of dragon bones faces pain points such as single machine models, cumbersome replacement, insufficient accuracy, and high labor costs, which have become bottlenecks restricting the scale development of enterprises. The emergence of Metal Steel Profile CD UD CU Drywall C U Channel Stud and Track Roll Forming Machine, with the core advantages of “intelligent, efficient, precise and durable”, reconstructs the keel production process and injects new upgrading momentum into building materials enterprises.

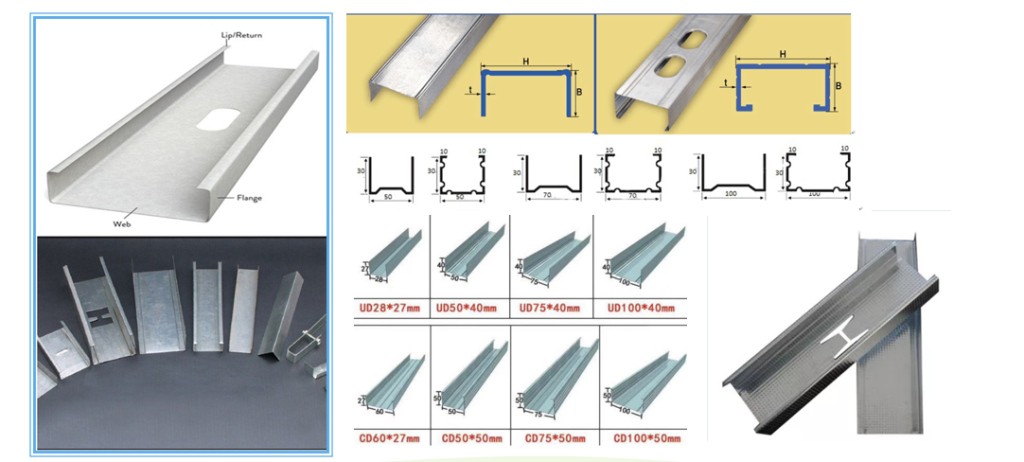

Profile drawing:

Application scenario:

• Commercial building decoration

The multi-purpose feature of the equipment significantly improves production efficiency, reduces material waste, and ensures accurate keel size to support the decorative structure of large commercial spaces, such as open shelf areas or partitions for brand counters.

• Office space and office buildings

Through automated production, the equipment provides high-precision keel, simplifies on-site construction, and shortens the construction period. For example, in office building renovation projects, the keel produced by this equipment can quickly build temporary or permanent partitions, improving space utilization.

• Industrial plants and storage facilities

The CU type keel machine supports customized production and can manufacture keels of different thicknesses and widths to meet the special needs of industrial environments. The factory production mode reduces on-site operations, lowers dust and noise pollution, and meets environmental standards.

• Residential buildings

The keel size produced by the equipment is precise, making it easy to achieve complex shapes such as curved ceilings. Its environmental characteristics also meet the demand for a healthy living environment in residential areas, reducing the formaldehyde emissions caused by traditional wooden keels.

Finished product image:

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness: 0.3-1.0mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

70m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Intelligent technology: a dual leap in precision and efficiency

Under the wave of automation and intelligent upgrading, the Metal Steel Profile CD UD CU Drywall C U Channel Stud and Track Roll Forming Machine integrates multiple core technologies to achieve precise control and efficient operation of the entire production process

-High precision forming system:

Cr12MoV alloy steel rollers are used, and after vacuum quenching treatment, the hardness reaches HRC58-62. Combined with multi pass continuous forming process, the forming tolerance is strictly controlled within ± 0.2mm, and the straightness error is ≤± 0.2mm, far higher than the industry standard. The size of the produced keel is uniform and the surface is flat, and it can be directly put into construction without secondary processing, greatly improving the product qualification rate and construction efficiency.

-Fully automated control:

Equipped with an imported PLC control system and LCD touch screen, operators only need to input parameters such as size and output, and the equipment can automatically complete the entire process of unwinding, feeding, punching, forming, cutting, and receiving. Only 1-2 workers are needed for a single production line, reducing labor costs by more than 70%. Equipped with an intelligent correction device, the position of the steel strip is monitored in real time and automatically adjusted to effectively prevent deviation, reducing the scrap rate from 5% of traditional equipment to below 1%.

-Efficient production capacity output:

Multiple production speed options are provided for different enterprise production capacity needs. The production speed of conventional models can reach 15-25 meters per minute, while high-speed models can exceed 50 meters per minute. The daily production capacity can reach up to 3000 meters, which is 50% more efficient than traditional equipment and easily meets large-scale production needs.