In the wave of iterative upgrading in the construction and building materials industry, Fully Automatic IBR Roof Machine Trapezoidal Metal Roll Forming Production Line have become the preferred roofing material for industrial plants, warehouses, large venues, and residential buildings due to their core advantages of smooth lines, compressive and wear-resistant properties, and excellent waterproofing. The key to determining the quality, production capacity, and profit margin of trapezoidal tiles is a set of high-performance production equipment. Choosing the right equipment not only allows you to stand firm in fierce competition, but also enables you to easily seize market dividends and achieve dual breakthroughs in production capacity and revenue!

Core features:

• Efficient production capacity empowerment, easy to undertake large orders.

• Precision quality control, creating core competitiveness in the market.

• Energy conservation, cost reduction, and overall profit potential enhancement.

Application Scenario:

1.In the field of industrial plants

Suitable for the needs of large heavy and light industry factories, the trapezoidal tiles produced are resistant to compression, wind, and corrosion, and can resist dust, acid and alkali erosion in industrial environments, ensuring long-term stability of the roof.

2.In the warehouse scene

Large span compatible tiles can be mass-produced, with excellent waterproof and moisture-proof performance, effectively protecting the safety of stored materials, and efficient installation to meet the needs of rapid warehouse construction.

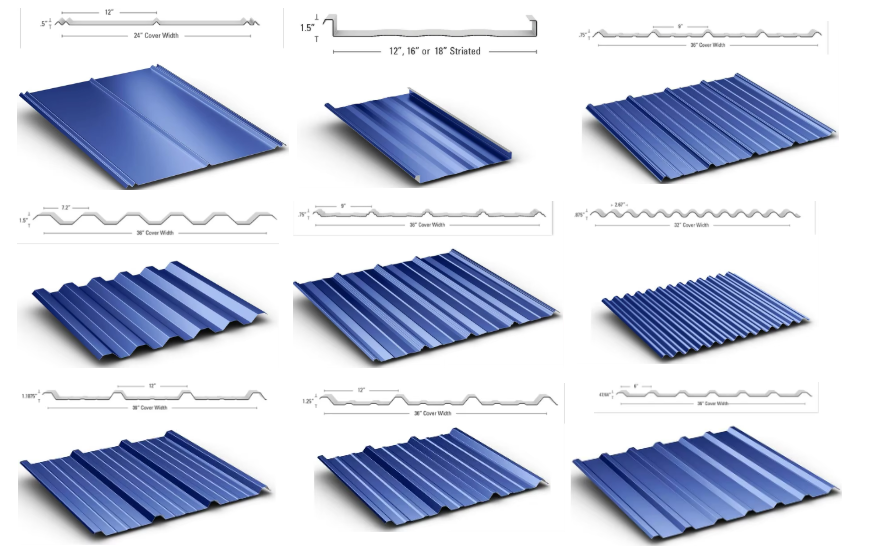

3.In large venue scenes

The equipment can be customized to produce trapezoidal tiles of different specifications and colors, which are in line with the overall design style of the venue. At the same time, the tiles are tightly spliced and have strong load-bearing capacity, suitable for large-span roof structures of the venue.

Product Attributes:

|

Main frame

|

350mm H beam structure

|

|||

|

Material of rollers

|

High grade 45 high quality steel by CNC machining and hard chrome coating

|

|||

|

Forming stations

|

16 stations

|

|||

|

Diameter of shafts

|

Φ70mm solid(Guaranteed)

|

|||

|

Material of shafts

|

High grade 45#,with heat treatment

|

|||

|

Forming speed

|

About 0-30m/min

|

|||

|

Voltage

|

380V/50HZ/3P

|

|||

|

Transmission way

|

By double chains

|

|||

|

Main motor

|

Servo motor 7.5kw,Yaskawa

|

|||

|

Cutting blade material

|

Cr12Mov quenched treatment to improve hardness

|

|||

|

Cutting type

|

Electric cutting

|

|||

|

Driving method

|

By motor,4 kw

|

|||

|

Cover

|

Whole cover for roll former,without cutter.2 parts can slide side to side easily.

|

|||