High Quality Metal Roof Panel Ridge Making Machine is a core building material processing equipment specifically designed for the large-scale, high-precision production of ridge tiles. It integrates the entire process of roll feeding, precise forming, automatic cutting, and finished product collection, and is compatible with various commonly used roofing tile materials such as color-coated steel sheets, galvanized steel sheets, aluminum alloy sheets, and stainless steel sheets. It can achieve customized production of ridge tiles in multiple specifications, including Chinese, Western, and antique styles. As a key processing equipment for roofing projects, this equipment overcomes the drawbacks of traditional manual forming and semi-automated processing. Its core competitiveness lies in “precise shaping, high-efficiency mass production, and stable reliability.” It integrates a precision mechanical structure and an intelligent control system, meeting the bulk supply needs of large-scale real estate projects as well as customized processing scenarios for ancient building restoration and distinctive residential construction, providing high-quality ridge tile production solutions for roofing material companies and contractors.

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness: 0.4-0.7mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler (will give you as free)

|

||

|

3.Main body

|

Roller station

|

14 rows (As your requirement)

|

||

|

Diameter of shaft

|

65mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

about 5500*1600*1600(customize)

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW, servo motor

|

||

|

Hydraulic system power

|

4KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

10-15m/min

|

The speed can be adjusted as customer’s request

|

||

Application scenario:

• In the civil construction sector

we produce Chinese-style pitched roof ridge tiles and Western-style villa ridge tiles for residences, villas, and rural self-built houses, precisely matching architectural styles while ensuring aesthetics and waterproofing, helping to create high-quality, livable spaces.

• In the industrial construction sector

we produce ridge tiles suitable for large buildings such as factories, warehouses, and cold chain logistics centers. The finished products are wind-resistant, pressure-resistant, and corrosion-resistant, suitable for the harsh environments of industrial settings.

• In the municipal and public building sector

we can customize irregularly shaped ridge tiles for distinctive buildings such as stadiums, stations, and cultural venues, meeting personalized design needs and enhancing the overall aesthetics and recognizability of the buildings.

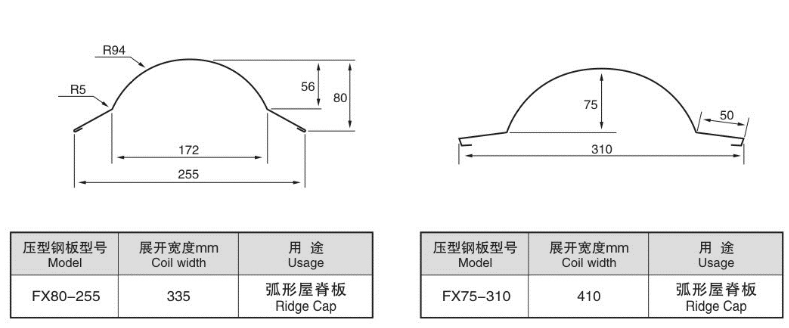

Pattern diagram:

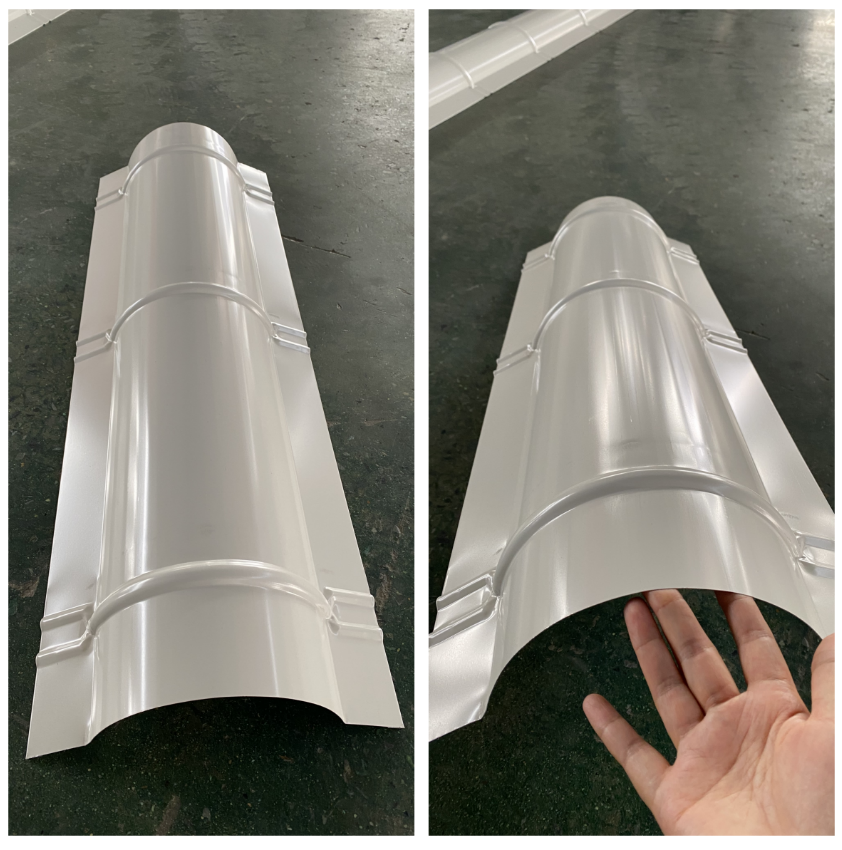

Finished product image:

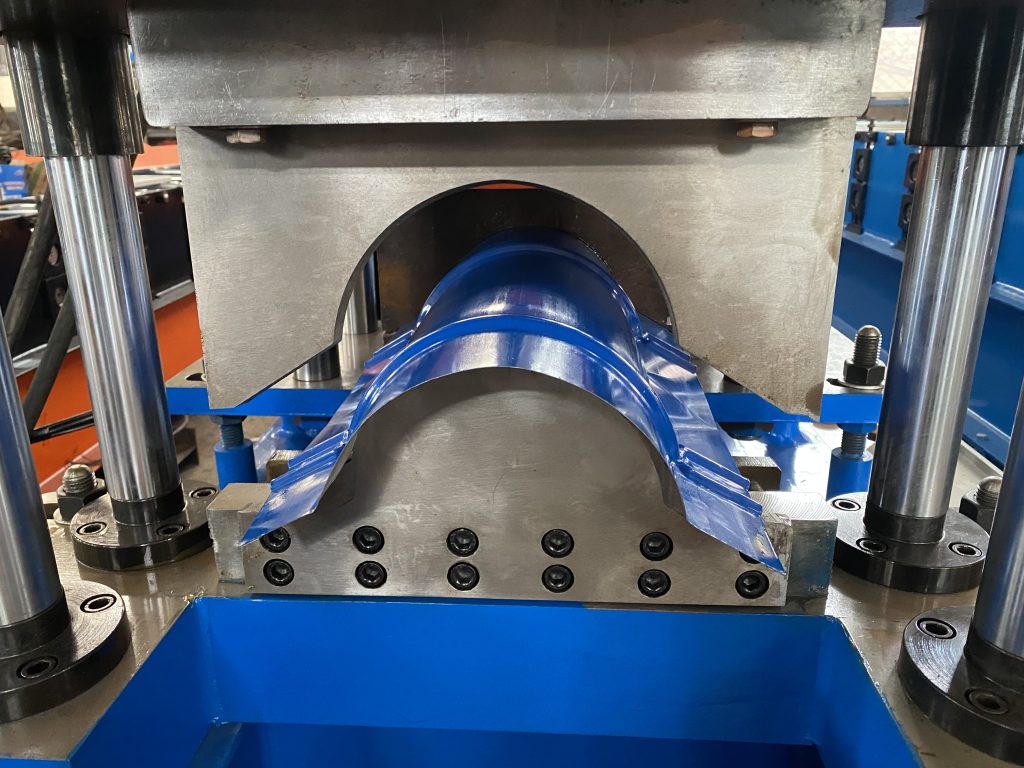

Core advantage:

1. Precise Shaping, Superior Quality:

Equipped with high-precision forming molds and a servo control system, the molds are CNC precision-ground to perfectly fit the ridge tile design. Servo motors precisely control forming pressure and speed, ensuring that the curvature, size, and overlap structure of each ridge tile are completely uniform, with errors controlled within ±0.5mm. This prevents roof sealing performance from being affected by shape deviations. Simultaneously, surface protection devices prevent scratches and deformation of the tiles during processing, resulting in a smooth, even surface and uniform color in the finished product, allowing for direct application to projects without secondary finishing.

2. High-Efficiency Mass Production, Flexible Switching:

Optimized transmission and feeding structures increase production speed by over 40% compared to traditional equipment, with a single-shift capacity of thousands of tiles, supporting 24-hour continuous and stable operation. Equipped with an intelligent touch-screen operating system, preset parameters for multiple ridge tile types allow for switching between different specifications and shapes within just 10 minutes, eliminating the need for complex manual adjustments and significantly reducing equipment downtime. This caters to both standardized mass production and small-batch customization needs.

3. Stable and durable with wide adaptability:

The machine body is made of high-strength steel welded in one piece and subjected to aging treatment to eliminate internal stress. It can withstand the vibration and load of long-term high-intensity operation and is not easily deformed. The forming mold is made of wear-resistant alloy material and undergoes special heat treatment, which extends the service life by more than 60% compared with ordinary molds. It supports the processing of plates with different thicknesses from 0.3-1.2mm and can be adapted to various metal materials and surface coatings. At the same time, it can customize exclusive molds according to customer needs to cover the ridge tile shape requirements of various roofing projects.